fuel activation device

A technology of fuel oil and oil flow, applied to internal combustion piston engines, charging systems, combustion engines, etc., can solve the problems of cumbersome installation and disassembly operations, limited activation of fuel oil, and dislocation and movement of permanent magnets, so as to improve the activation effect and improve Magnetization effect, enhanced effect of change

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

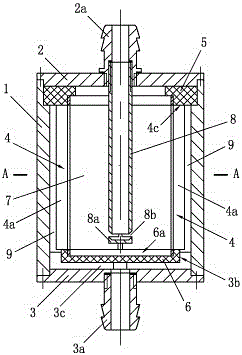

[0034] It includes a housing 1, one end of the housing is connected to the first end cover 2, the first end cover 2 is provided with an oil inlet joint 2a, the other end of the housing is connected to the second end cover 3, and the second end cover 3 is provided with an oil outlet Connector 3a, see figure 1 ; During implementation, the housing and end caps should avoid materials that affect the magnetic field.

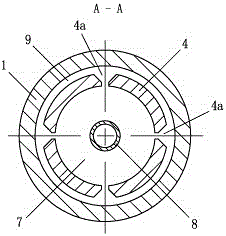

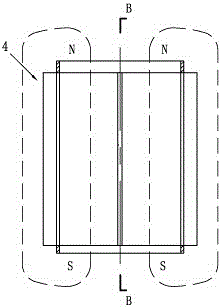

[0035] A permanent magnet cylinder 4 is arranged in the housing 1, such as figure 1 , Figure 3 to Figure 5 As shown, the permanent magnet cylinder 4 is an integral structure, the upper end of the permanent magnet cylinder 4 is provided with a seal ring 5, and the seal ring 5 cooperates with the first end cover 2 and the inner wall surface of the housing 1 to form a sealing structure. The permanent magnet cylinder 4 The lower end is provided with a sealing plate 6, which constitutes the sealing structure of the lower port of the permanent magnet cylinder 4, see ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com