Afterheat discharging pump for third-generation nuclear power technology AP1000

A technology of waste heat removal and technology, which is applied to components, pumps, pump devices, etc. of pumping devices used for elastic fluids. It can solve the problem that the locking structure cannot meet the requirements of nuclear power plant alternating loads and cannot guarantee the complete function of the pump group. Insufficient, unable to meet the installation space of nuclear power plants and other issues, to achieve the effect of compact overall structure size, simple structure, and meet the requirements of installation space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be described in further detail below in conjunction with the accompanying drawings.

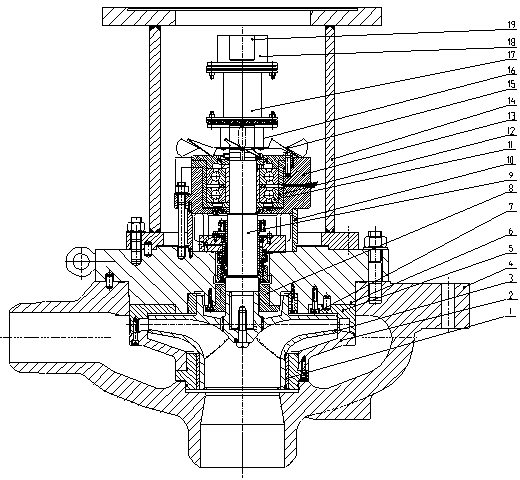

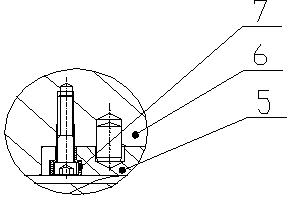

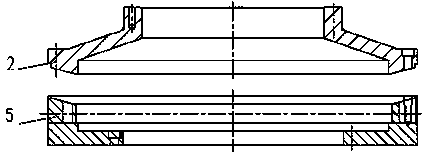

[0032] as attached figure 1 As shown, the waste heat removal pump for third-generation nuclear power technology (AP1000) provided by the present invention has a vertical, single-stage, single-suction, cantilever, and radially split structure. The working medium is sucked in from the bottom of the pump and discharged horizontally. The main components of the pump include impeller wear ring 1, pressure chamber cover plate 2, impeller 3, pump body 4, pressure chamber 5, pump cover 6, cup-shaped locking sleeve 7, throat bushing 8, pump shaft 9 , bearing bracket 10, bearing 11, bearing box 12, bearing box 13, motor bracket 14, forced cooling fan 15, pump end mounting plate 16, extended interval shaft 17, motor end mounting plate 18 and motor output shaft 19, etc.; The cover is a multi-level matching surface, which is matched with the pump body, motor bracket, bea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com