Halogen lamp packaging structure, packaging tooling and packaging method of biochemical analyzer

A biochemical analyzer, packaging structure technology, applied in the sealing between tube and shell components, incandescent lamps, incandescent lamp parts and other directions, can solve problems affecting instrument stability, large thermal expansion coefficient, filament position changes, etc. The method is simple and easy to implement, the thermal expansion rate is low, and the effect of ensuring stable work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0049] Embodiment of Halogen Lamp Encapsulation Structure of Biochemical Analyzer

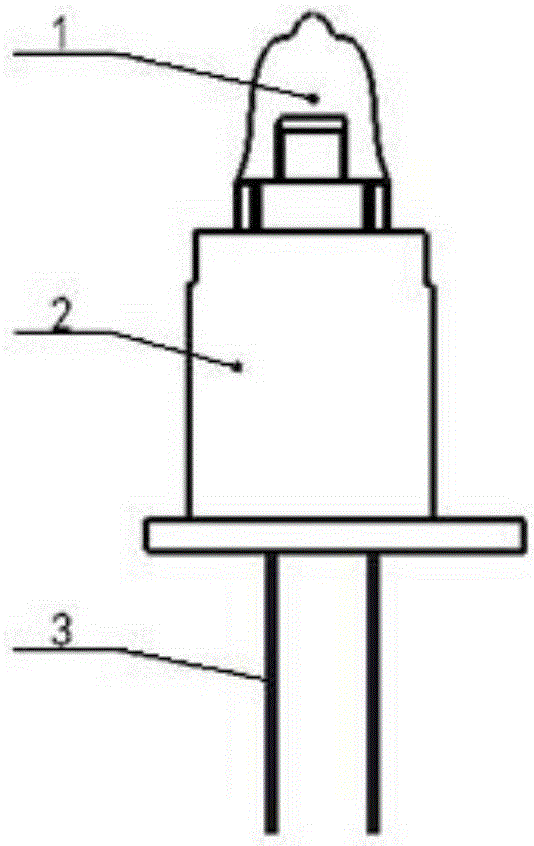

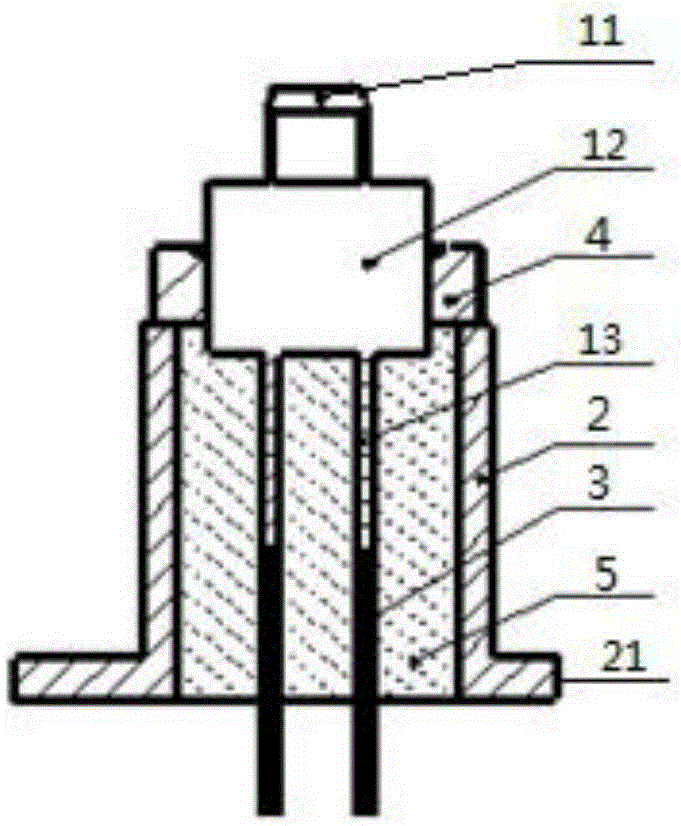

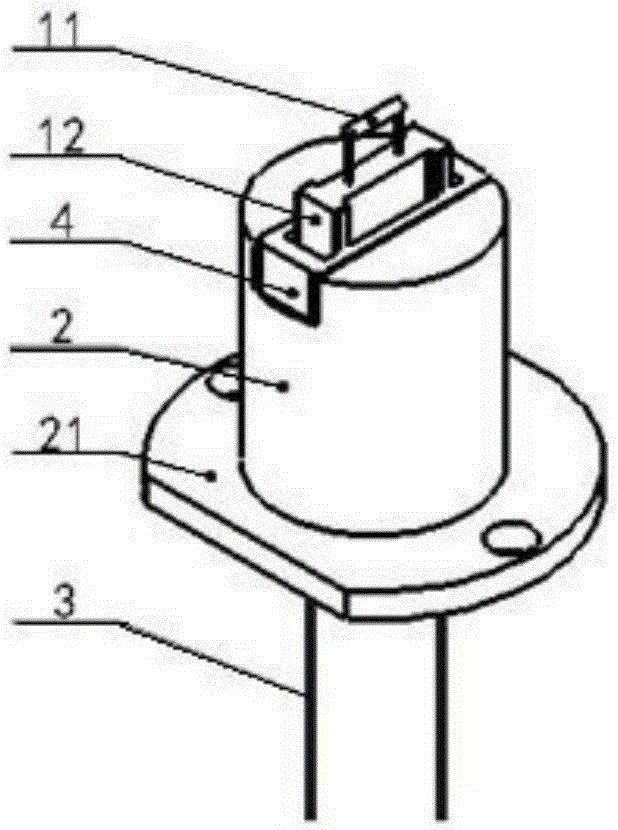

[0050] Examples of halogen lamp packaging structures of this biochemical analyzer figure 1 As shown, it includes a halogen lamp 1, a wire 3, and a lamp body fixing cylinder 2. The lamp body fixing cylinder 2 is a hollow cylinder, the outer diameter of the cylinder is smaller than the aperture of the lamp mounting hole of the light source seat 6, and the top of the cylinder has an integrated top cover with a concave flat groove on the top cover, and the thickness of the top cover is equal to or less than The depth of the flat groove, the bottom of the flat groove communicates with the hollow inner cavity of the lamp body fixing tube 2 , and the length and width of the flat groove are greater than the length and width of the lamp body 12 of the halogen lamp 1 . Such as figure 2 and 3 As shown, the clamping seat 4 is a cuboid, the length and width of the outer contour and the length and width ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com