Automatic fire-extinguishing patch board

A technology of automatic fire extinguishing and plug-in boards, which is applied in the direction of electrical components, coupling devices, circuits, etc., can solve the problems of low safety and achieve the effects of high safety, simple structure and convenient installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

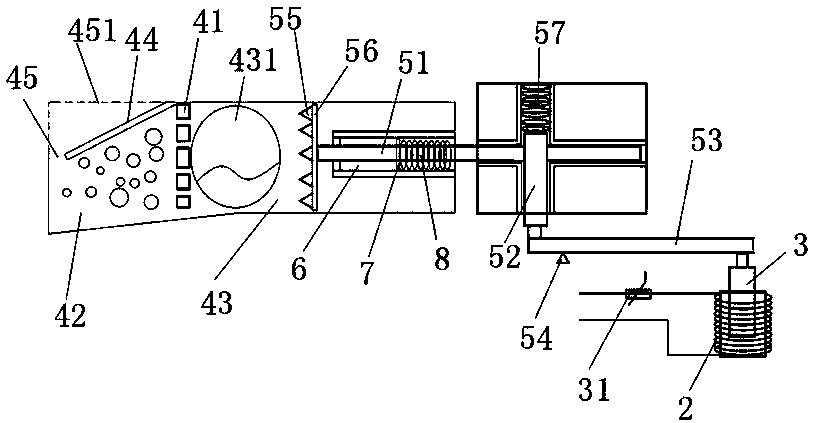

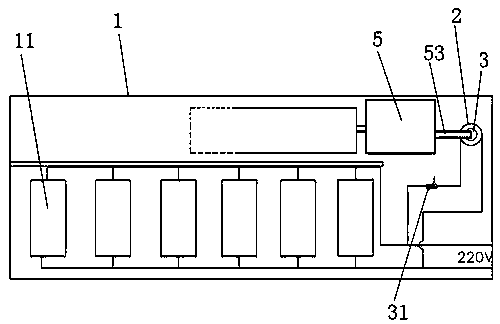

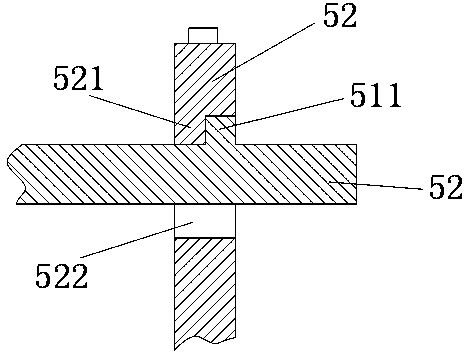

[0039] An automatic fire extinguishing plug board, comprising a plug board housing 1 and a socket 11 arranged in the plug board housing 1, the housing 1 is provided with fire extinguishing equipment, and the fire extinguishing equipment includes a braking device and a reaction device, the reaction device includes a reaction box, and the reaction box is provided with a baffle 41 that separates the reaction box into two communicating areas. Both sides of the baffle 41 are reactant chambers, and the braking device includes A coil 2 connected in parallel to the socket, a negative thermistor 31 connected in series with the coil 2, an iron rod 3 inserted in the coil 2 to move up and down, and a push rod assembly that brakes through the iron rod 3 and extends into the reaction box.

[0040] The stopper 41 is a plurality of stoppers arranged vertically or a partition with through holes, wherein the reactant chamber on the front side of the stopper 41 is a solid reactant chamber 42, an...

Embodiment 2

[0051] The difference from the above embodiment is that the stopper 41 is a plurality of stoppers arranged obliquely and transversely or a partition with through holes, and the reactant cavities on the upper and lower sides of the stopper 41 are liquid storage chambers 43. A liquid storage bag 431 is arranged in the liquid bag cavity 43 , and a bag pressing part is arranged at the front end of the push rod assembly. A limit projection is arranged on the lower surface of the stopper to ensure that the lower fluid storage bag will not slide forward.

[0052] The reactants can be two kinds of liquids arranged up and down, that is, a liquid compound for reaction is stored in each liquid storage bag, and the liquid storage bag is punctured by the bag-punching part, and the liquid in the upper liquid storage bag passes through the gap between the stoppers. The through holes in the gap or partition flow down and mix with the reaction liquid located in the lower part, thereby producin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com