Electric energy multiplication device named 'electric multiplication motor'

A technology of electric energy and electric energy conversion, applied in electromechanical devices, control mechanical energy, electrical components, etc., can solve problems such as electromechanical products that have not yet been seen, and achieve the effect of reducing quality and eliminating frictional resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

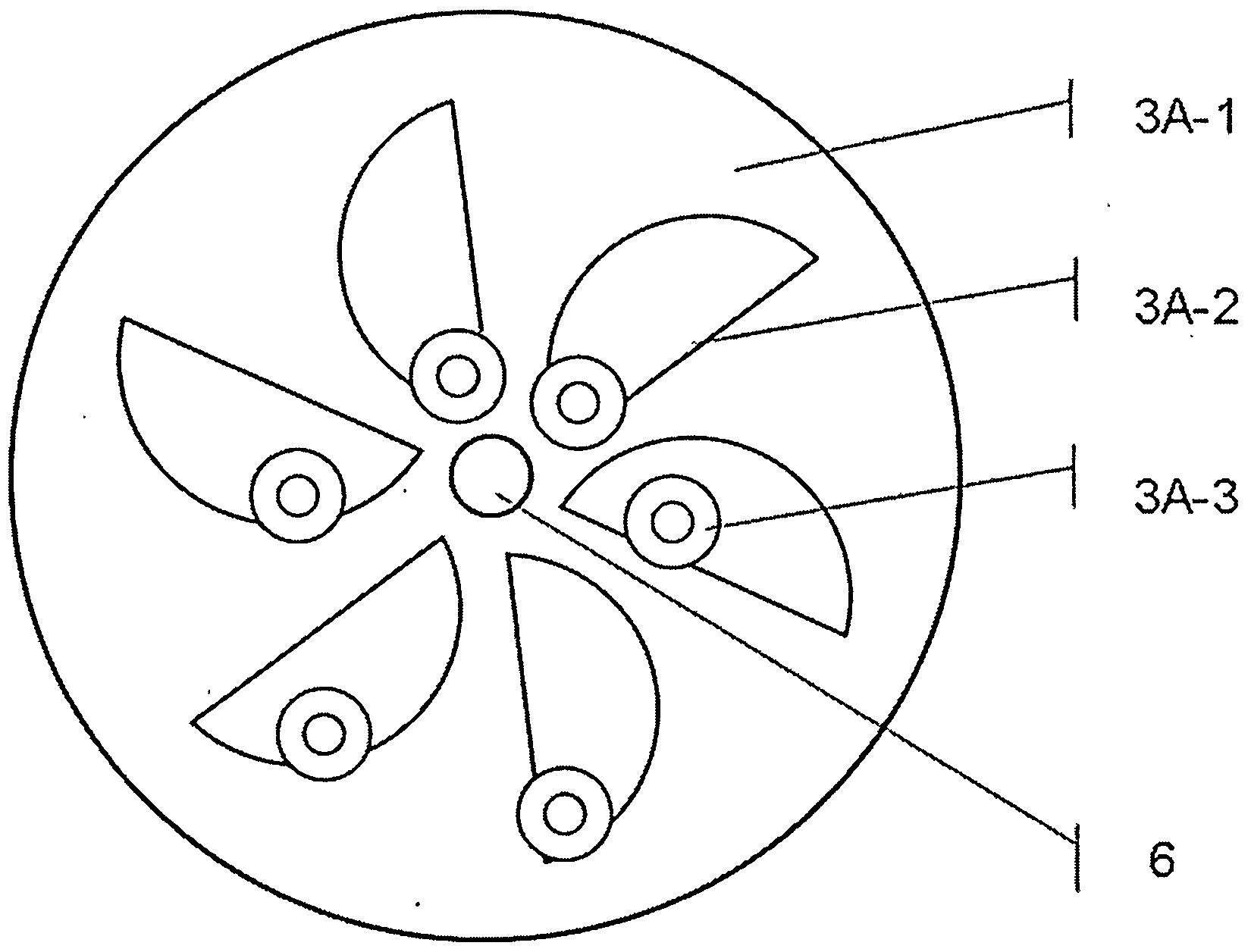

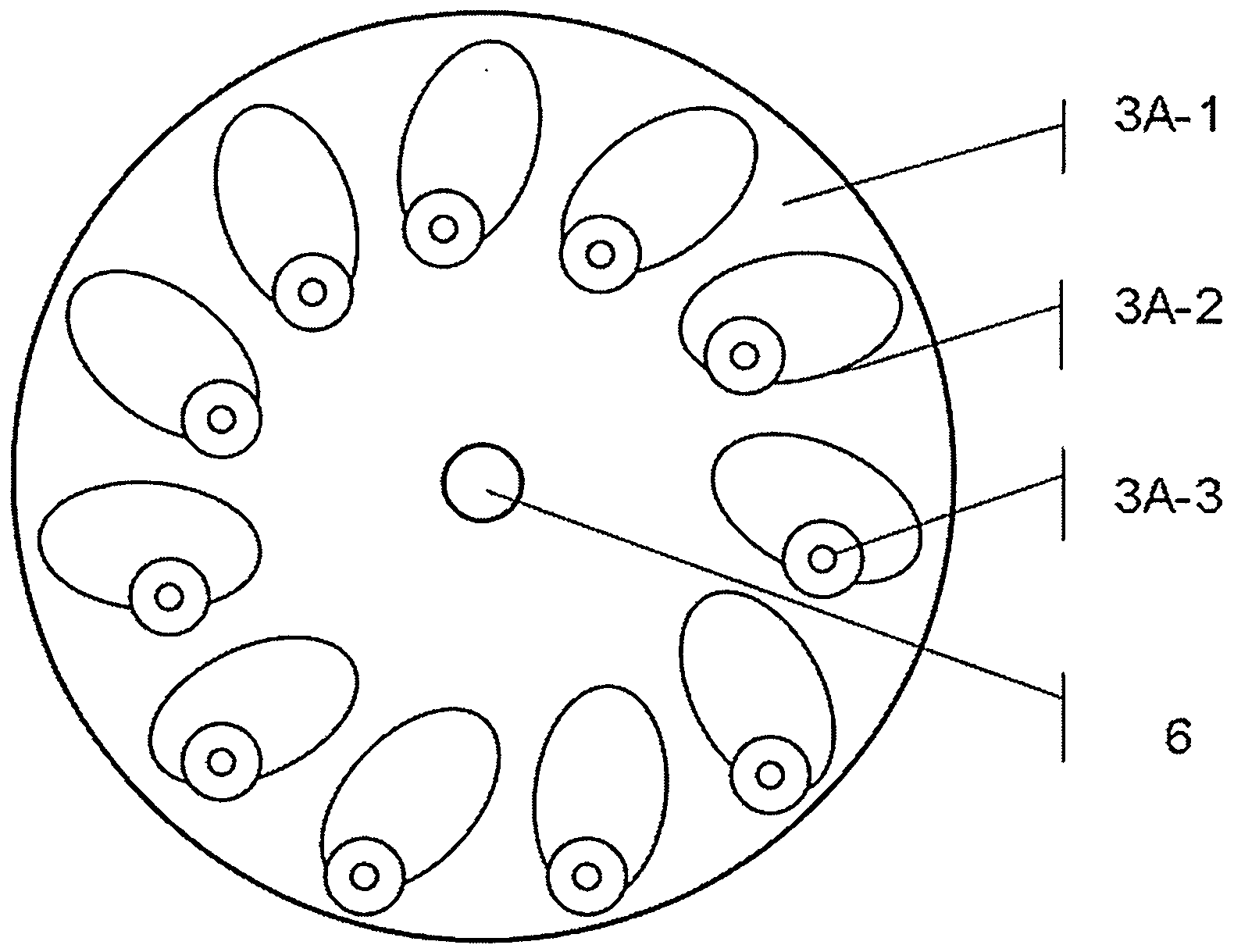

[0080] a kind of like Figure 16 The power multiplication device named "motor booster" shown includes electric unit 1, power generation unit 2, flywheel 3A, control system 4, power conversion device 5, stationary shaft 6, bearing 7, fan 8, frame 9, end The cover 10, the base 11, and the cooling rib 12 are characterized in that:

[0081] (1) The "motor booster" is a horizontal concentric structure, and its essence is to nest the smaller outer rotor permanent magnet motor 1 and the larger inner rotor permanent magnet generator 2 together, The permanent magnet rotor 2-2 of the power generation unit is suspended outside the permanent magnet rotor 1-2 of the electric unit and can rotate accordingly under the action of magnetic force;

[0082] (2) The stator 1-1 of the electric unit is composed of iron core, winding, insulating lining, and junction box. Winding on the slot teeth where the insulating lining is laid, or the winding coil can be wound first and then embedded in the wi...

Embodiment 2

[0091] a kind of like Figure 16 The power multiplication device named "motor booster" shown includes electric unit 1, power generation unit 2, flywheel 3A, control system 4, power conversion device 5, stationary shaft 6, bearing 7, fan 8, frame 9, end The cover 10, the feet 11, and the cooling ribs 12 are characterized in that: the arrangement of the permanent magnets of the electric unit rotor and the generator unit rotor is a Halbach array formed by radial, tangential, and obliquely magnetized fan-shaped permanent magnets, and the magnetic energy The reinforced side faces the air gap side outward; the flywheel uses gravity and magnetic force to assist the flywheel. The rest of the implementation details are the same as Example 1.

Embodiment 3

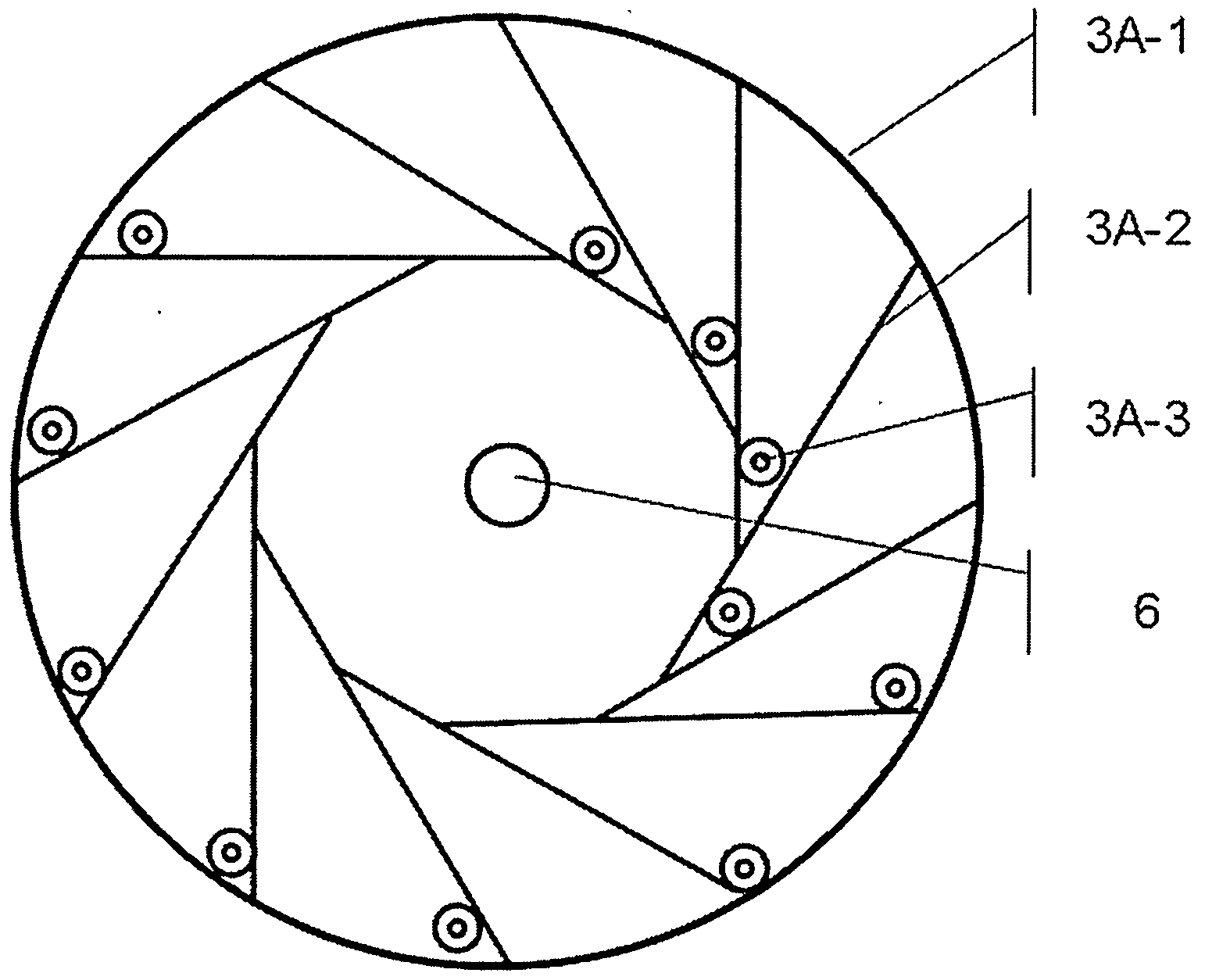

[0093] a kind of like Figure 17 The power multiplication device named "motor booster" shown includes electric unit 1, power generation unit 2, flywheel 3A, control system 4, power conversion device 5, stationary shaft 6, bearing 7, fan 8, frame 9, end The cover 10, the ground feet 11, and the heat dissipation ribs 12 are characterized in that: the rotor 1-2 of the electric unit and the rotor 2-2 of the power generation unit are combined into one, and the inner and outer layers are permanent magnet rotors, that is, on the annular back yoke An annular iron core is arranged, and permanent magnets are respectively arranged on the outer circumference of the annular iron core and the wall of the inner hole. Other than that, other implementation details are the same as those in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com