Graphite mould used for manufacturing local reinforcement aluminum matrix composite materials

An aluminum-based composite material and graphite mold technology, which is applied in the field of graphite molds, can solve the problems of low carbon content, long reaction time, complicated devices, etc., and achieve the effects of good filling, rapid response and simple structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be further explained below with reference to specific embodiments.

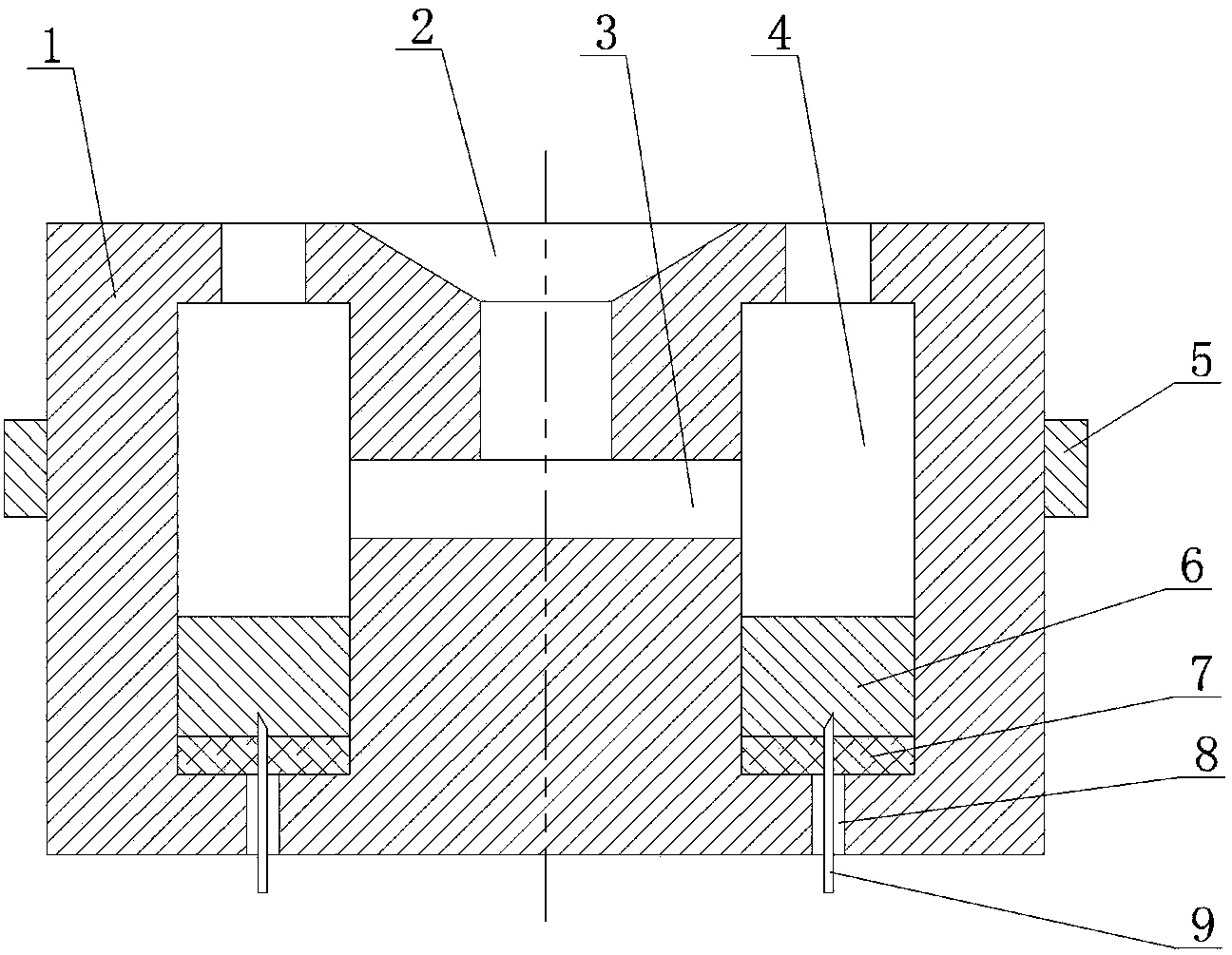

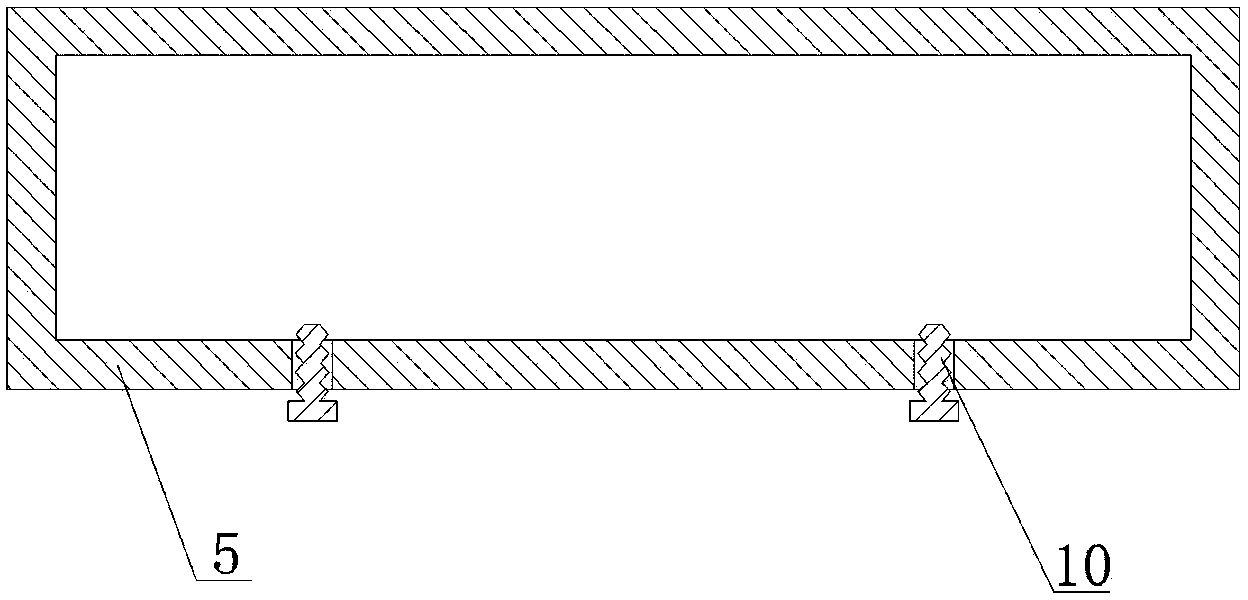

[0013] Reference figure 1 , figure 2 , The graphite mold for preparing partially reinforced aluminum-based composite materials according to the present invention includes a graphite mold body 1 and a fastening iron frame 5. The graphite mold body 1 has a rectangular parallelepiped structure, and two aluminum melt filling chambers 4 with a cylindrical structure are arranged inside it. An aluminum melt pouring port 2 is arranged between the two aluminum melt filling chambers 4, and the aluminum melt The melt pouring inlet 2 is in communication with the aluminum melt filling chambers 4 on both sides through the aluminum melt channel 3. The bottoms of the two aluminum melt filling chambers 4 are respectively provided with vent holes 8, above the vent holes 8 are provided with a quartz sand pad 7, and the two vent holes 8 are both inserted with tungsten rhenium thermocouples 9, Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com