Steel pipe inner burr tool

A burr and steel pipe technology, applied in the field of argon arc welding machine auxiliary equipment, can solve the problems of easy corrosion of the bulge at the weld, the decrease of the fluid flow rate in the pipe, and the reduction of the service life of the steel pipe, so as to shorten the abnormal processing time, improve the Cleaning efficiency and ensuring the effect of performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

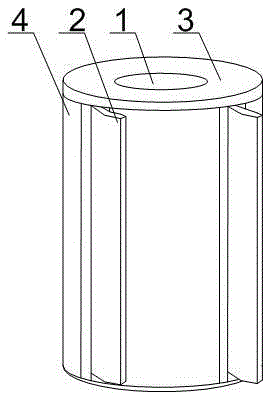

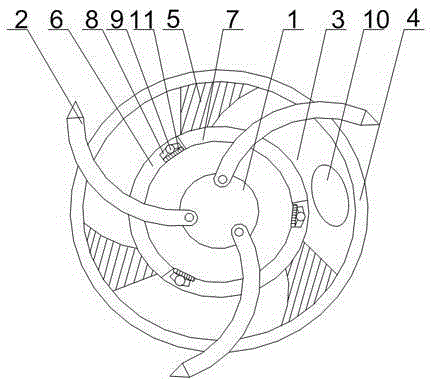

[0020] Such as figure 1 and figure 2 As shown, the welded steel pipe outer burr cleaning mechanism of the present invention includes a central shaft 1 on which three arc-shaped blades 2 are arranged, and the three arc-shaped blades 2 are hinged to the central shaft 1 and are respectively located on the central shaft. On one-third of the outer wall of 1, a fixed plate 3 is installed at the upper and lower ends of the central axis 1 and the arc blade 2 is arranged between the two fixed plates 3, and the fixed plate 3 is also provided with a stopper 5, the stopper One side of 5 is an arc-shaped concave surface and the arc-shaped concave surface is in contact with the arc outer line of the arc-shaped blade 2, and also includes a blade 2 angle adjustment mechanism arranged between the arc-shaped blades 2; the blade 2 angle adjustment mechanism includes a connecting rod 7 and the connecting piece 6, the connecting rod 7 and the connecting piece 6 are respectively connected with th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com