Method for extracting colloid

A technology of colloid and extract, which is applied in the field of chemical industry and can solve problems such as environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

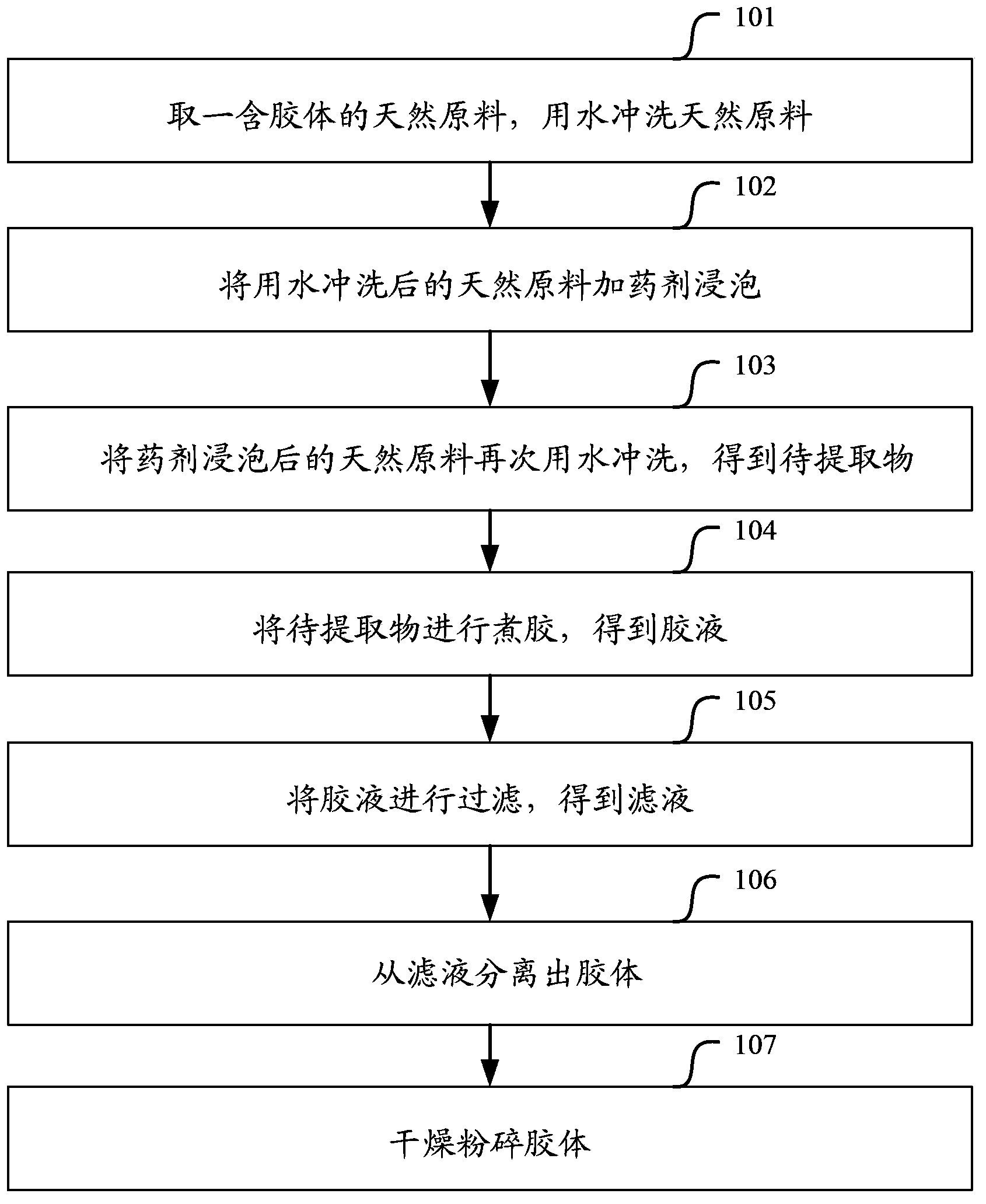

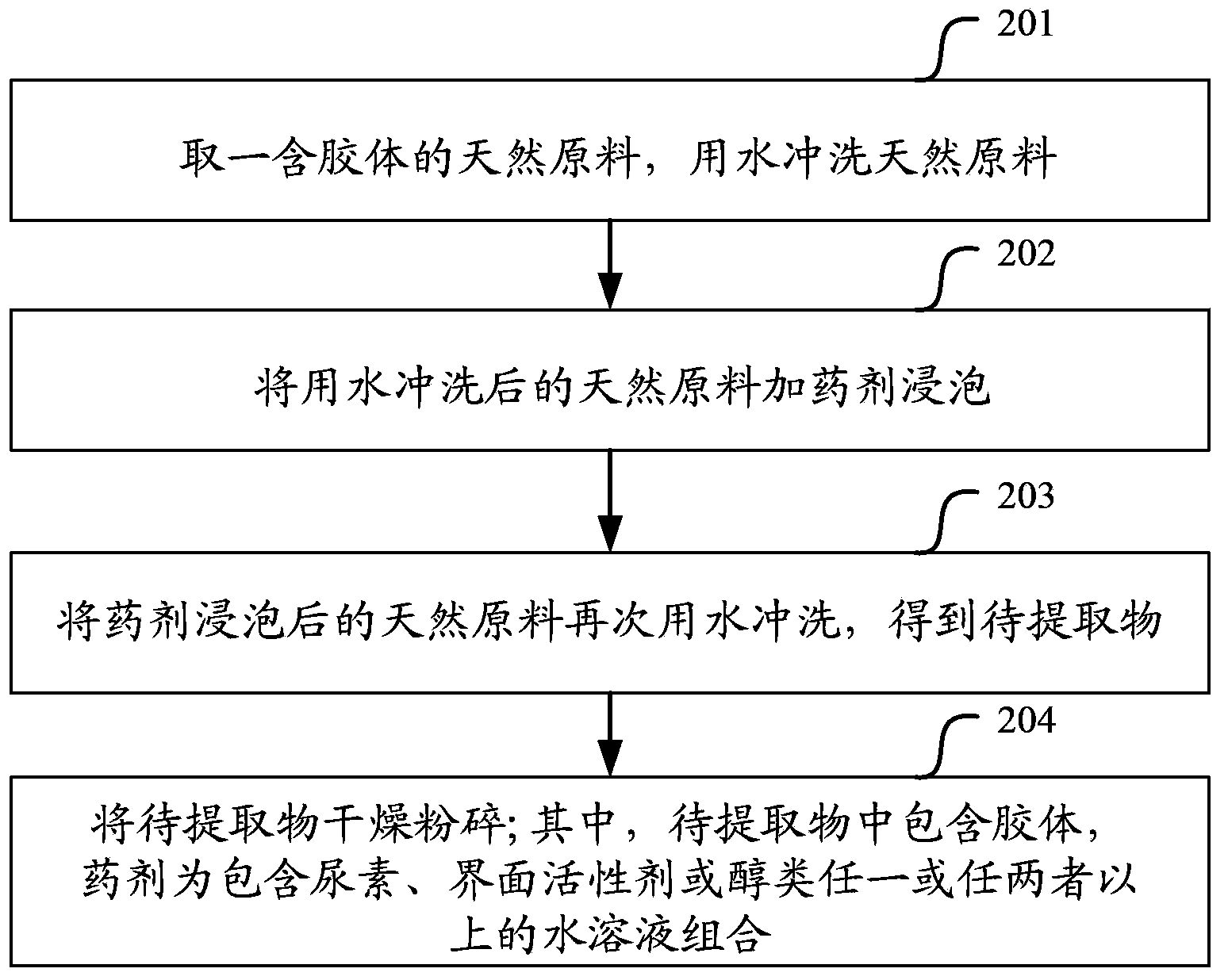

Method used

Image

Examples

Embodiment 1

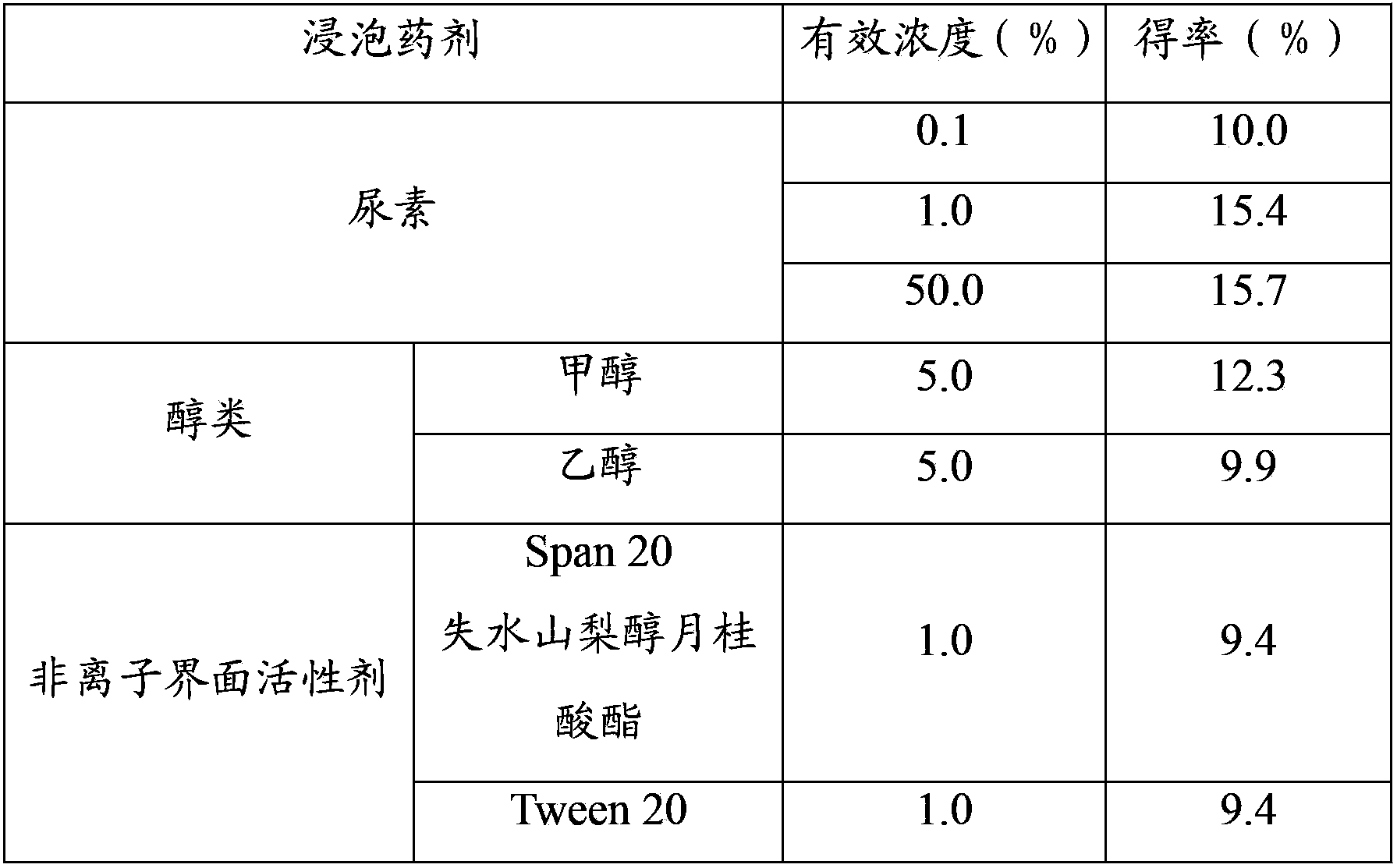

[0070] Embodiment 1 Soaking agent is urea, alcohols or surfactant.

[0071] First weigh 10 grams of Eucheuma auricularis, and wash the Eucheuma auricularis with a large amount of clear water; add the cleaned Eucheuma auris into the soaking agent (the soaking agent can be selected from the following table 1), and soak for 24 hours , the temperature of soaking the medicament is 45°C; the Eucheuma auricularis after soaking in the medicament is washed again with a large amount of clear water to obtain an extract to be extracted; adding potassium chloride with a concentration of 2% by weight is added to the extract to be extracted Heating and boiling the glue, the temperature of the glue boiling is 70°C-100°C (preferably 95°C-100°C), the cooking time of the glue is 2 hours, and the glue is obtained; the filter aid diatomaceous earth is added to the glue, and At a temperature of 70°C-100°C, filter with filter paper to obtain the filtrate; use the freeze-thaw method to separate the c...

Embodiment 2

[0082] Example 2 Extraction of colloids in Pteris chinensis, Eucheuma heterocladum and Eucheuma auris.

[0083] Take 10 grams of algae by weighing (respectively the three kinds of algae enumerated in the following table 3), and clean this algae with a large amount of clear water; Add the urea aqueous solution that the weight percent concentration of urea in water is 1% to the algae after cleaning, soaking temperature is 45°C, soaking time is 24 hours; wash the algae soaked in the agent with a large amount of water again to obtain an extract; add potassium chloride with a concentration of 2% by weight, heat and boil the extract The temperature is 70°C-100°C (preferably, 95°C-100°C), and the time for cooking the glue is 2 hours to obtain the glue; Suction filtration with filter paper at 70°C-100°C to obtain filtrate; separate the colloid from the filtrate by freeze-thaw method; dry the colloid to obtain the finished product.

[0084] According to the test, it is determined that...

Embodiment 3

[0087] Example 3 The soaking agent is a combination of urea or alkali.

[0088] Weighing takes 30 grams of algae (Europa auricularis), and cleans this algae with a large amount of clear water; The algae after cleaning is added the urea aqueous solution that the weight percentage concentration of urea in water is 1%, 5% or 10%, and sodium hydroxide The weight percent concentration in water is 0% (no addition), 3% or 9% sodium hydroxide aqueous solution for immersion, the immersion temperature is 0 ℃, 25 ℃ and 45 ℃ respectively, and the immersion time is 1, 3 and 6 hours respectively ; Wash the algae soaked in the medicament with a large amount of water again to obtain an extract; add potassium chloride with a concentration of 2% by weight, and heat and boil the extract to be gelatinized. The temperature of the boiled gelatin is 70°C-100°C (Preferably, 95°C-100°C), boil the glue for 2 hours to obtain the glue; add filter aid diatomaceous earth to the obtained glue, and use filte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com