Hosiery machine stitch cams and cam system

A technology of triangle system and yarn bending triangle, which is applied in the direction of textiles and papermaking, weft knitting, knitting, etc., can solve the problems of ignoring the improvement, ignoring the improvement of hosiery machine operation mode and component structure, etc., so as to improve the operation efficiency and good application value effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

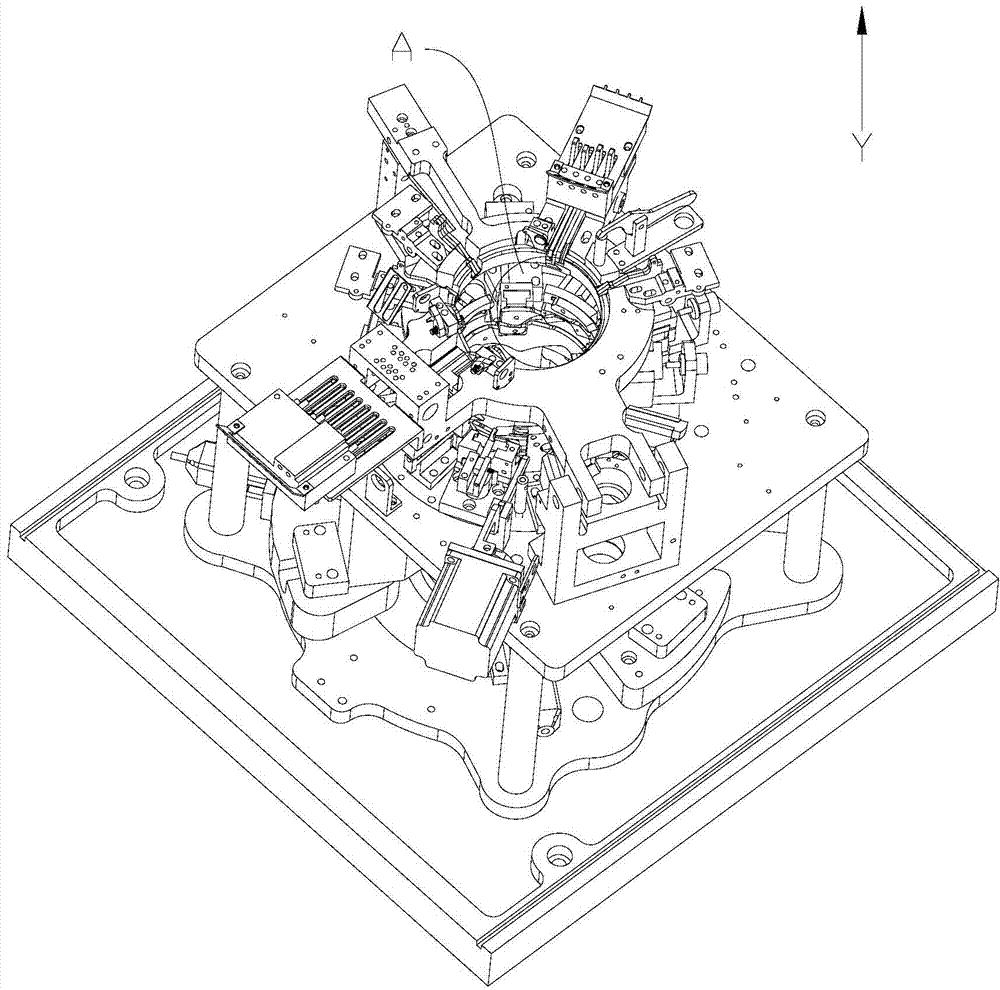

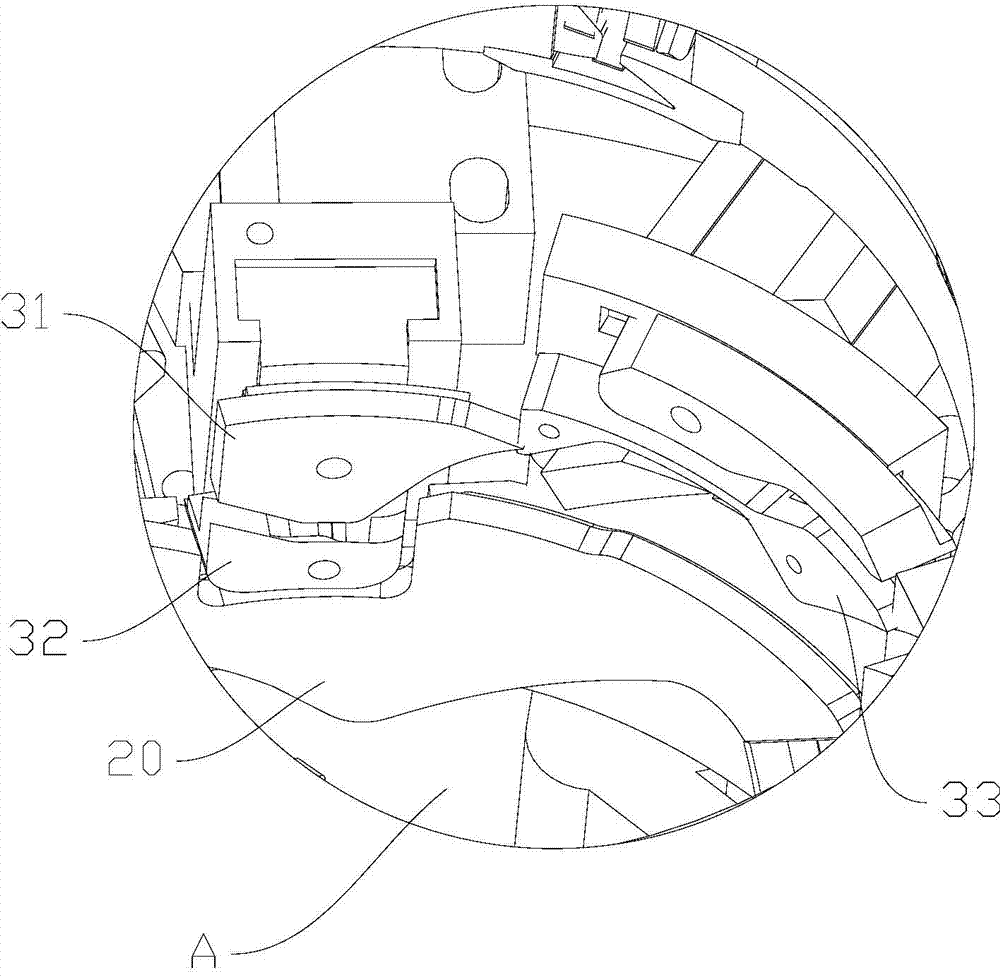

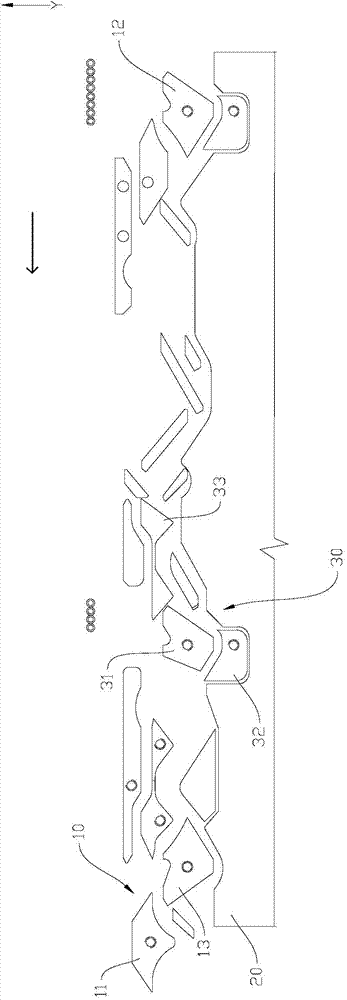

[0025] Hosiery machine triangle system, such as Figure 1-5 As shown, it includes the main road triangle system 10, the middle steel ring 20 and an additional auxiliary road triangle system 30. The main road triangle system 10 and the auxiliary road triangle system 30 are respectively located on both sides of the middle steel ring 20. Usually, the main road triangle system 10 is located on the opposite side of the auxiliary road cam system 30 in the circumferential direction of the middle steel ring 20; the main road cam system 10 includes the upper middle cam 11, the left yarn bending cam 12 and the right yarn bending cam 13; the auxiliary road cam system 30 includes Auxiliary road bending cam 31, auxiliary road insert 32 and flat needle plate 33, flat needle plate 33 is a strip plate arranged along the circumferential direction of middle steel ring 20, and the two ends of flat needle plate 33 are bent towards the auxiliary road Two protrusions are arranged in the direction o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com