Square steel pipe column-h-shaped steel beam splicing outer sleeve connection method

A connection method, the technology of H-shaped steel, which is applied in the direction of construction and building construction, can solve the problems of difficult built-in positioning, difficult operation process, and many welded parts, and achieves the effects of convenient construction, shortened construction period, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0021] The present invention will be described in detail below with reference to the drawings and specific embodiments.

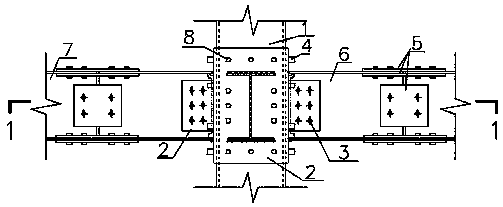

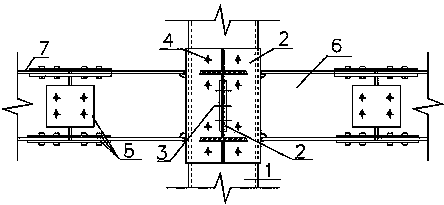

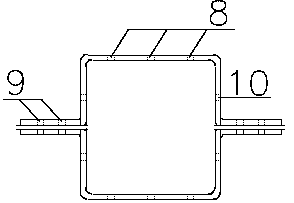

[0022] Such as Figure 1 to Figure 5 As shown, the present invention is a square steel pipe column-H-shaped steel beam splicing outer sleeve type connection method, which is mainly composed of square steel pipe column 1, U-shaped splicing outer plate 2, high-strength bolts 3, high-strength core bolts 4, splicing cover Plate 5, cantilever H-shaped steel short beam 6, H-shaped steel beam 7, plug welding hole 8, eversion lug plate 9 and core bolt hole 10. The square steel pipe column 1 has several groups, one of which is opposite to the pipe wall Corresponding core bolt holes 10 are provided on the U-shaped splicing outer shell plate 2 and corresponding core bolt holes 10 and plug welding holes 8 are also provided on the U-shaped splicing outer shell plate 2. The U-shaped splicing outer shell plate 2 is connected with the core through the high-strength core bolt ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com