Extended type multi-platform railway tunnel operation trolley

An extended platform and multi-platform technology is applied in the field of extended multi-platform railway tunnel operation trolleys to achieve the effects of improving operation efficiency, reducing operation difficulty, and reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

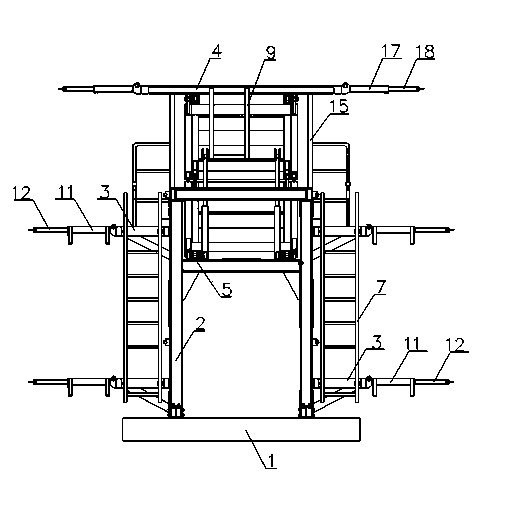

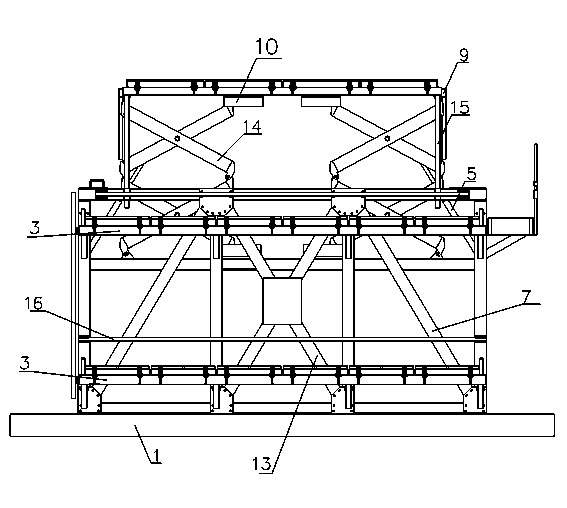

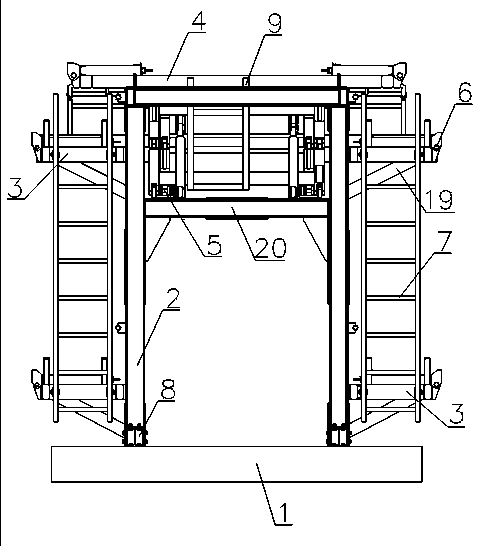

[0017] Such as Figure 1 to Figure 5 As shown, the extended multi-platform railway tunnel operation trolley includes a rail flat car 1, a door frame device, a side fixed working platform 3, a scissor lifting mechanism, and a top fixed lifting platform 4. The door frame device is composed of a door frame column 2. The crossbeam 20 and the oblique support 13 are connected to form, and the gantry column 2 is fixed on the rail flat car 1 by bolts; the left and right sides of the gantry device are symmetrically provided with four side fixed working platforms 3 with different heights. The side fixed working platform 3 and the door frame device are connected by fixed welding; the side fixed working platform 3 is connected with a side turning expansion platform 11 that can be turned 180° through the movable hinge 6 provided, and the side turning expansion platf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com