Circular section synchronous rotary jet grouting device

A grouting device and section technology, which is applied to shaft equipment, shaft lining, mining equipment, etc., can solve the problems of unfavorable grouting to control the formation of mud jacket, slow grouting effect and small grouting amount, etc. Body deformation, reduce friction, control the effect of land subsidence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments, but the protection scope of the present invention should not be limited thereby.

[0025] The circular cross-section synchronous rotary jet grouting device of the present invention is installed between the tool pipes at the tail of the pipe jacking machine, and advances together with the pipe jacking machine, and can inject grout around the pipe jacking machine in time to quickly and evenly form the mud sleeve, effectively Reduce the friction between the tunnel segment and the soil, and fill the shield tail gap.

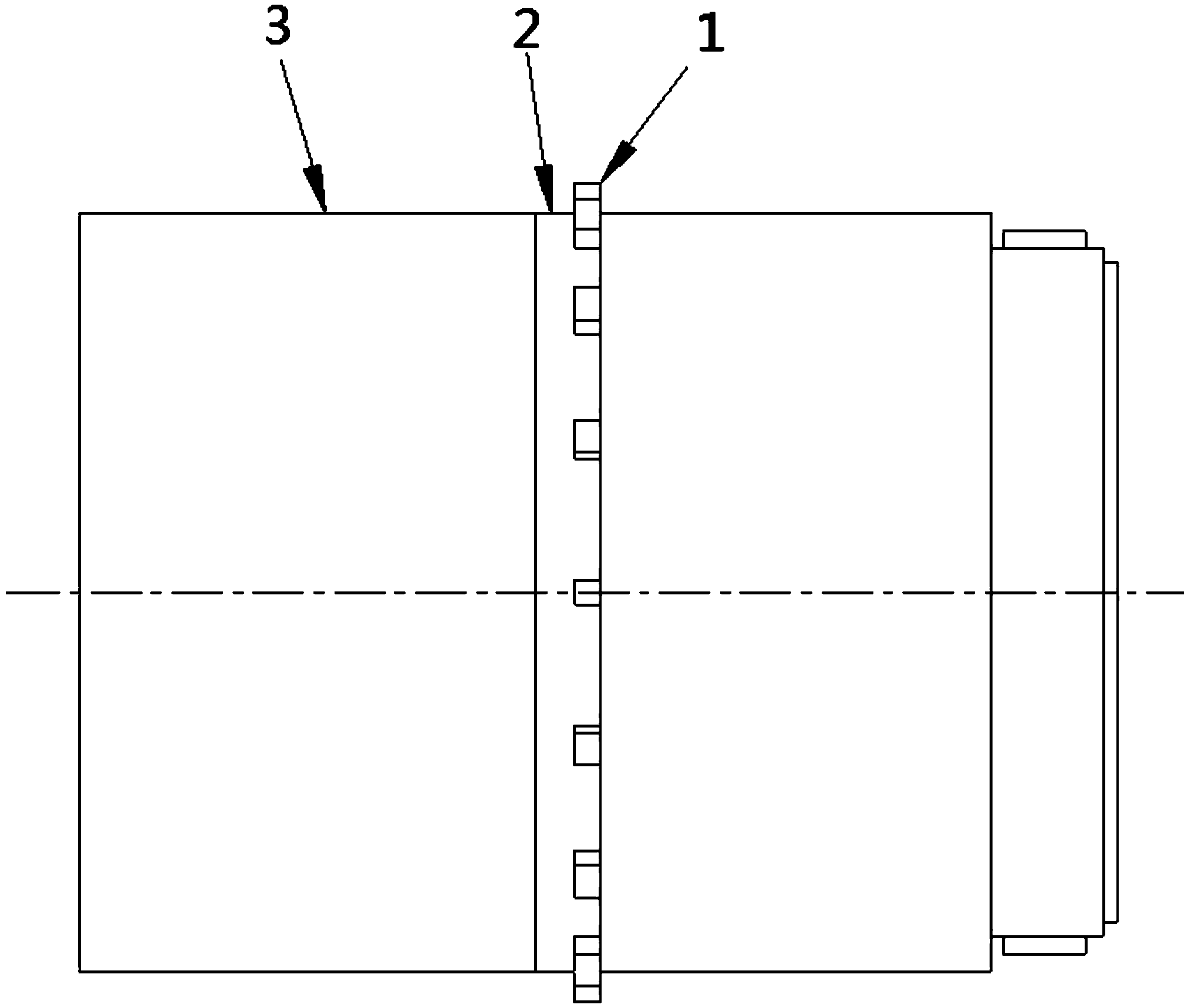

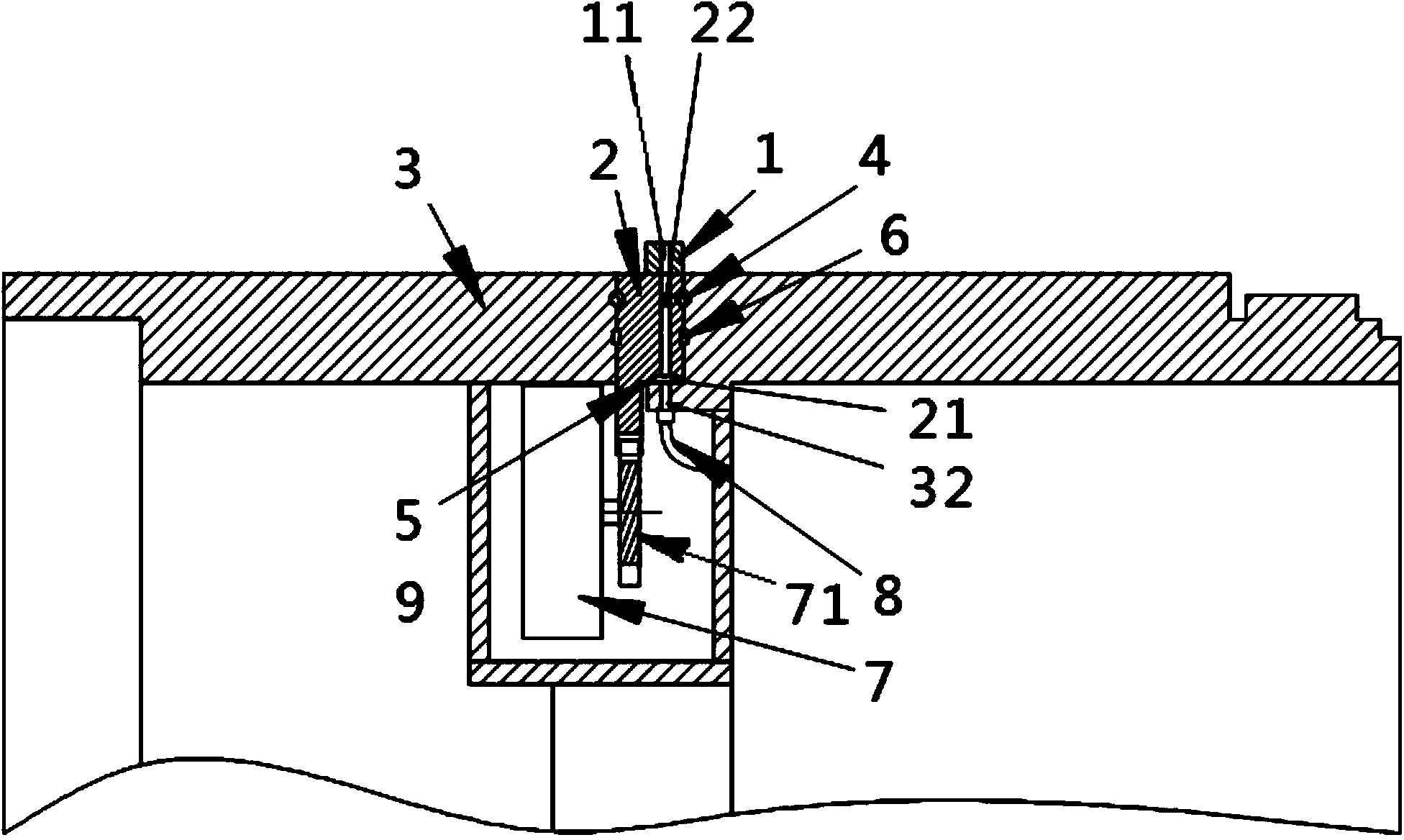

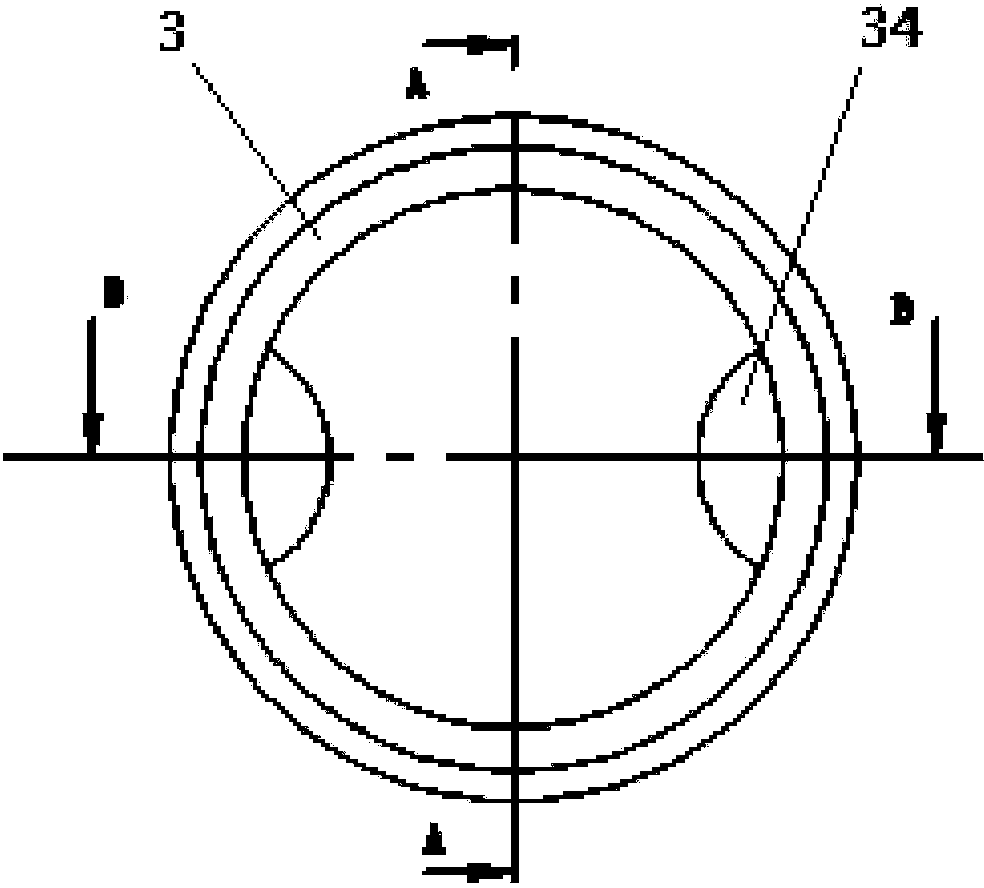

[0026] see figure 1 and figure 2 , the diagram shows a circular cross-section synchronous rotary jet grouting device including a steel pipe section 3, a grouting pipe 8, a swivel 2, a motor 7 and a number of nozzles 1.

[0027] Please refer to figure 2 , image 3 , Figure 4 and Figure 5 , the two ends of the steel pipe section...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com