Energy-saving type high-flow high-pressure water pump and method for high-pressure washer

A technology of a high-pressure cleaner and a high-pressure water pump, which is applied to the cleaning method using liquid, the parts of the pumping device used for elastic fluid, the cleaning method and tools, and can solve the problem of not being able to increase the flow rate of the high-pressure water pump itself and not being able to improve the cleaning effect and other problems, to achieve the effect of strong versatility and applicability, simple structure, and increased water flow range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0049] The technical scheme of the present invention will be further described in conjunction with the accompanying drawings and specific embodiments, which is believed to be clear to those skilled in the art.

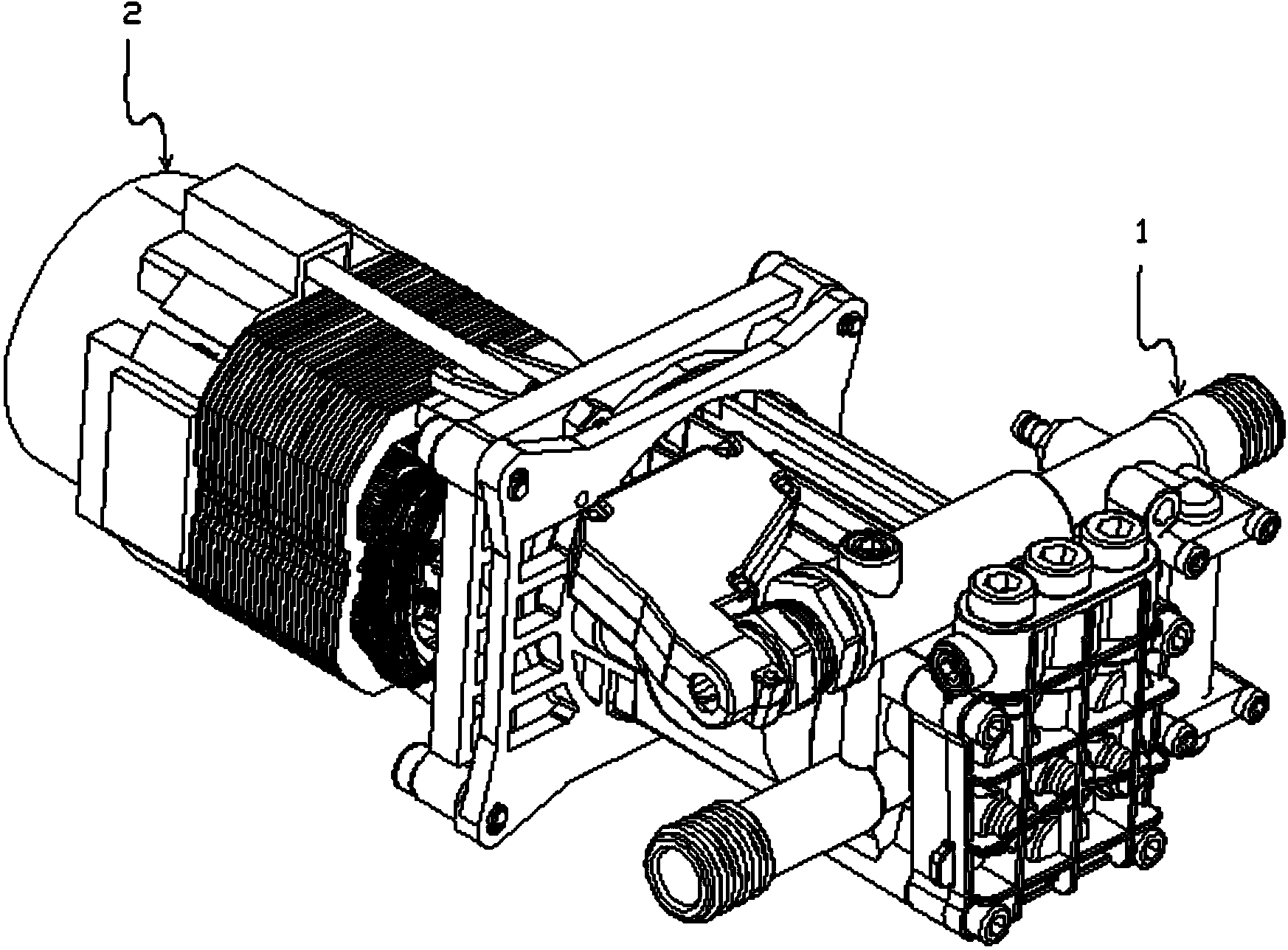

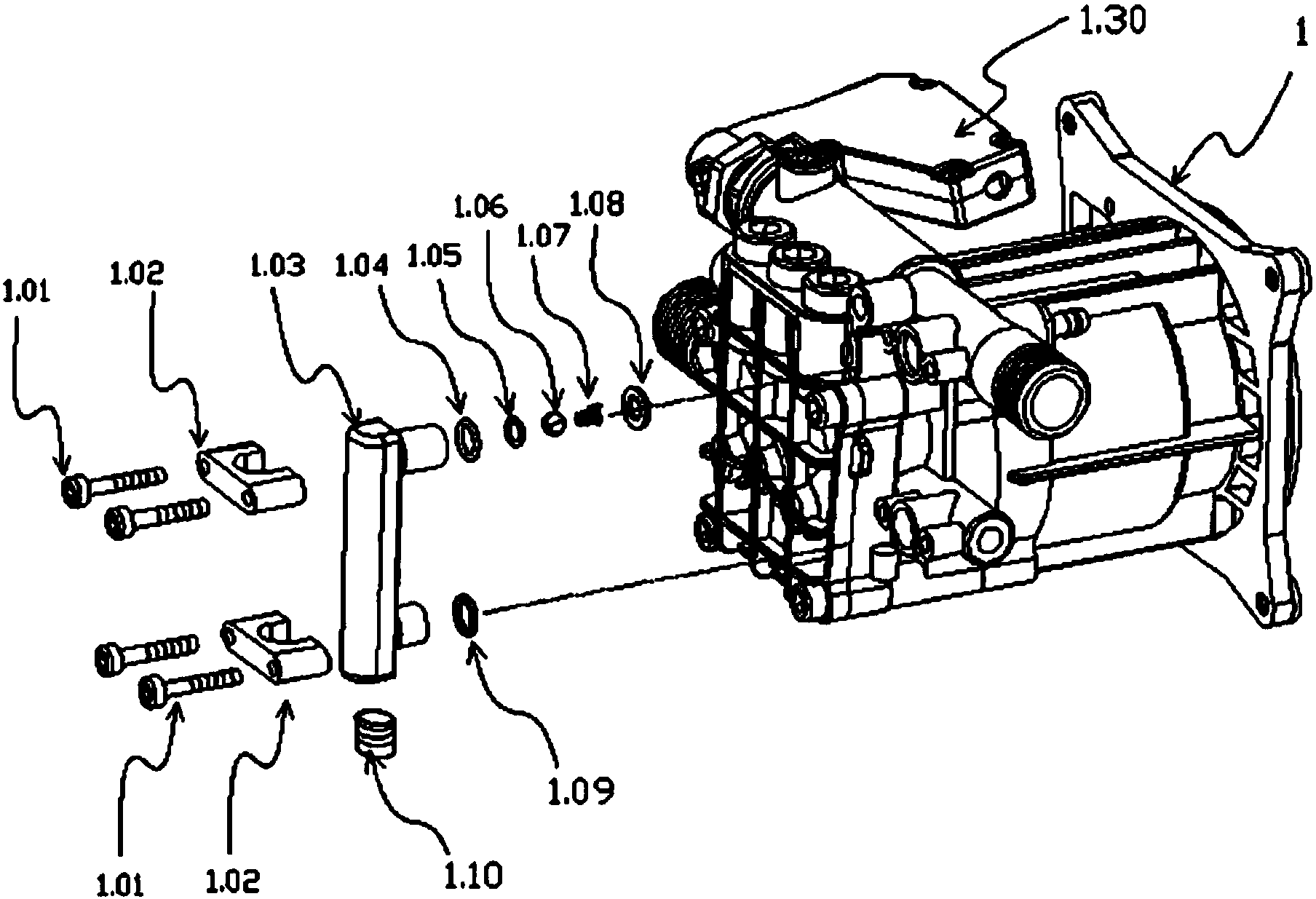

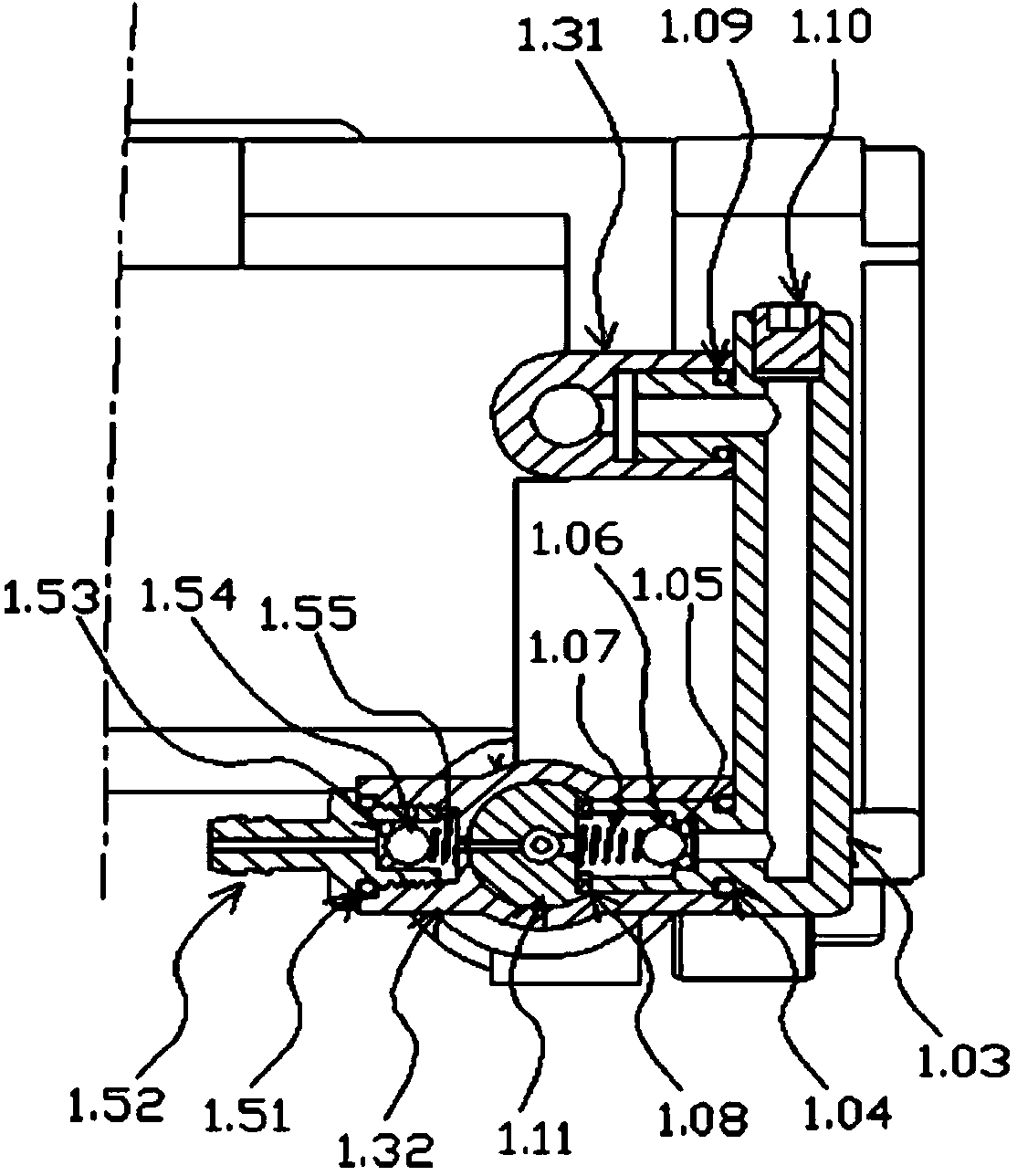

[0050] As shown in the figure, the energy-saving high-flow high-pressure water pump in this embodiment, such as figure 1 As shown, the high-pressure water pump assembly 1 is connected by the motor assembly 2, and the high-pressure water pump assembly 1 is connected by the transmission control of the motor assembly 2. Its structure and principle follow the traditional design of the cleaning machine industry, and no further analysis is made. The high pressure water pump assembly such as Figure 2-3c , consisting of a pump body, a high-pressure water inlet pipeline, a high-pressure water outlet pipeline, a double-stage throttle valve, a large flow valve group and a cleaning liquid valve group,

[0051] A two-stage throttling Venturi valve is arranged in the pump body, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com