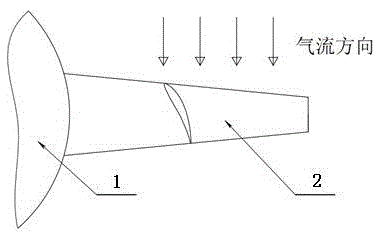

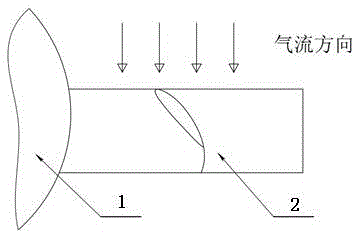

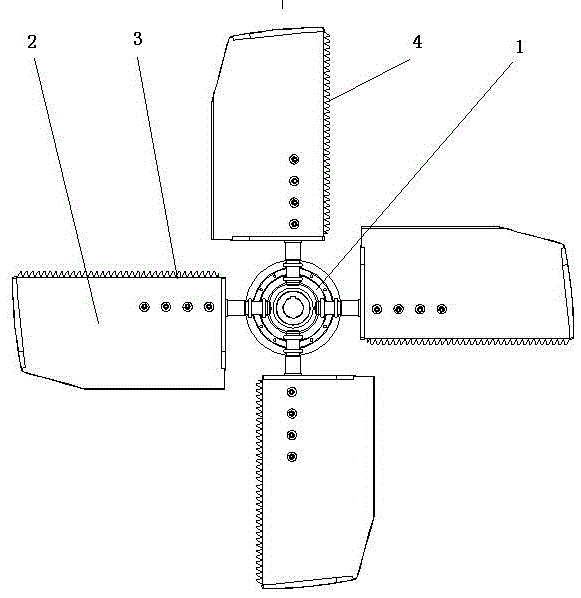

Large axial flow impeller with toothed leading edge blades

An axial flow impeller and blade technology, applied in the field of axial flow fans, can solve the problems affecting the aerodynamic performance of the impeller, impeller noise, etc., and achieve the effects of excellent aerodynamic performance, low resistance and novel structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0019] Example: Take the impeller of φ1830, and pass the comparative test of the straight leading edge blade and the serrated blade leading edge blade, set the height of the impeller blade leading angle of attack 4 as H, the width of the blade as B, and the apex angle of the leading angle of attack as a , the angle between the leading edge and the height of the leading angle of attack is a1, and the angle between the trailing edge and the height is a2. The specific test steps are as follows: 1. Fully open the adjustment door,

[0020] 2. Turn on the power switch, adjust the power supply voltage and frequency according to the requirements of the motor, and test run the fan to ensure that the direction of operation is correct.

[0021] 3. Run the fan and observe the motor tester. When the frequency reaches the rated frequency, adjust the power supply voltage to make it reach the rated voltage. When the voltage jumps ±5V, check the current value of the motor tester.

[0022] 4. I...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com