Light emitting device and related projection system thereof

A light-emitting device and excitation light technology, which is applied to lighting devices, projection devices, lighting device components, etc., can solve the problem of large loss of laser light

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

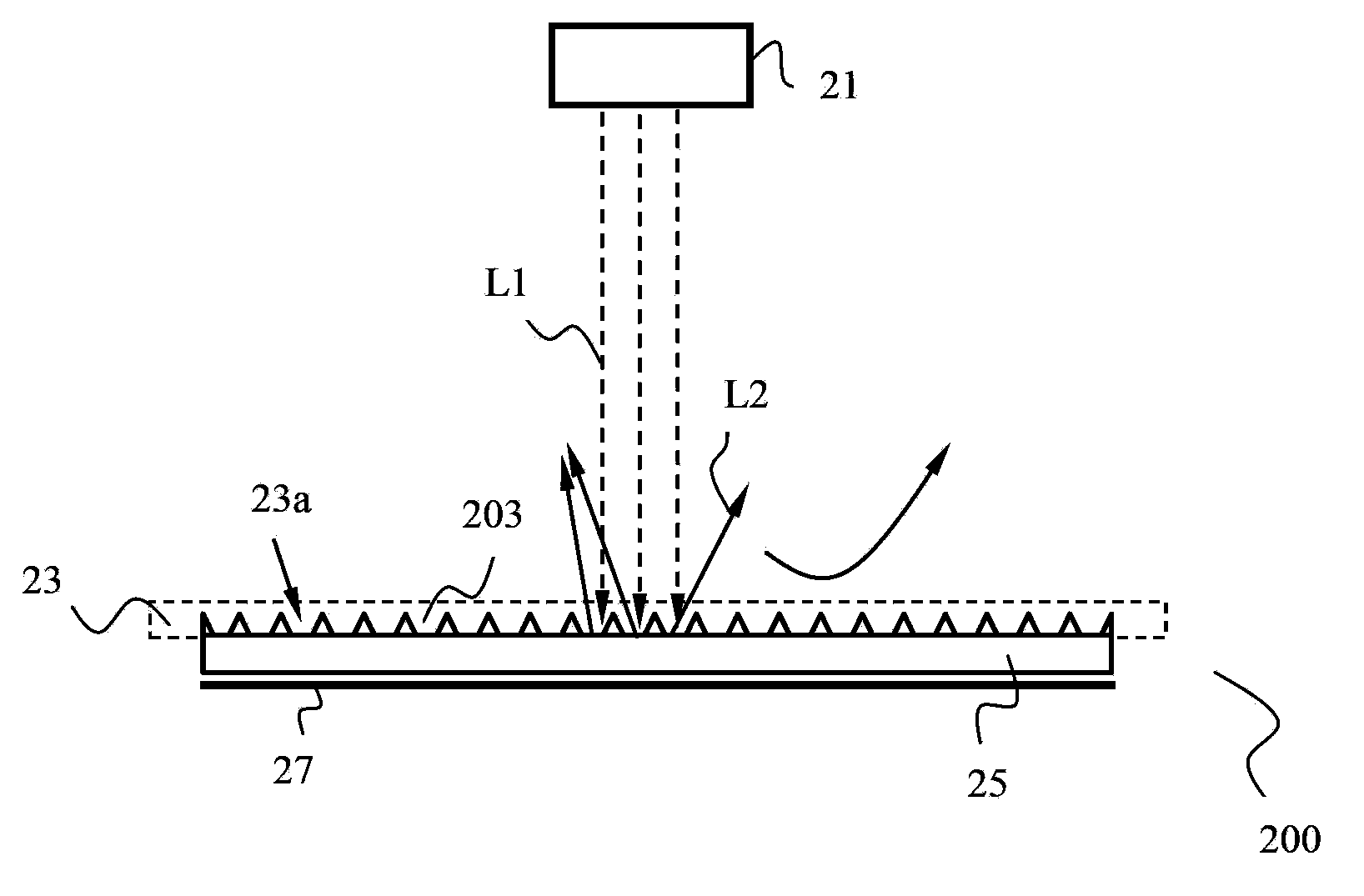

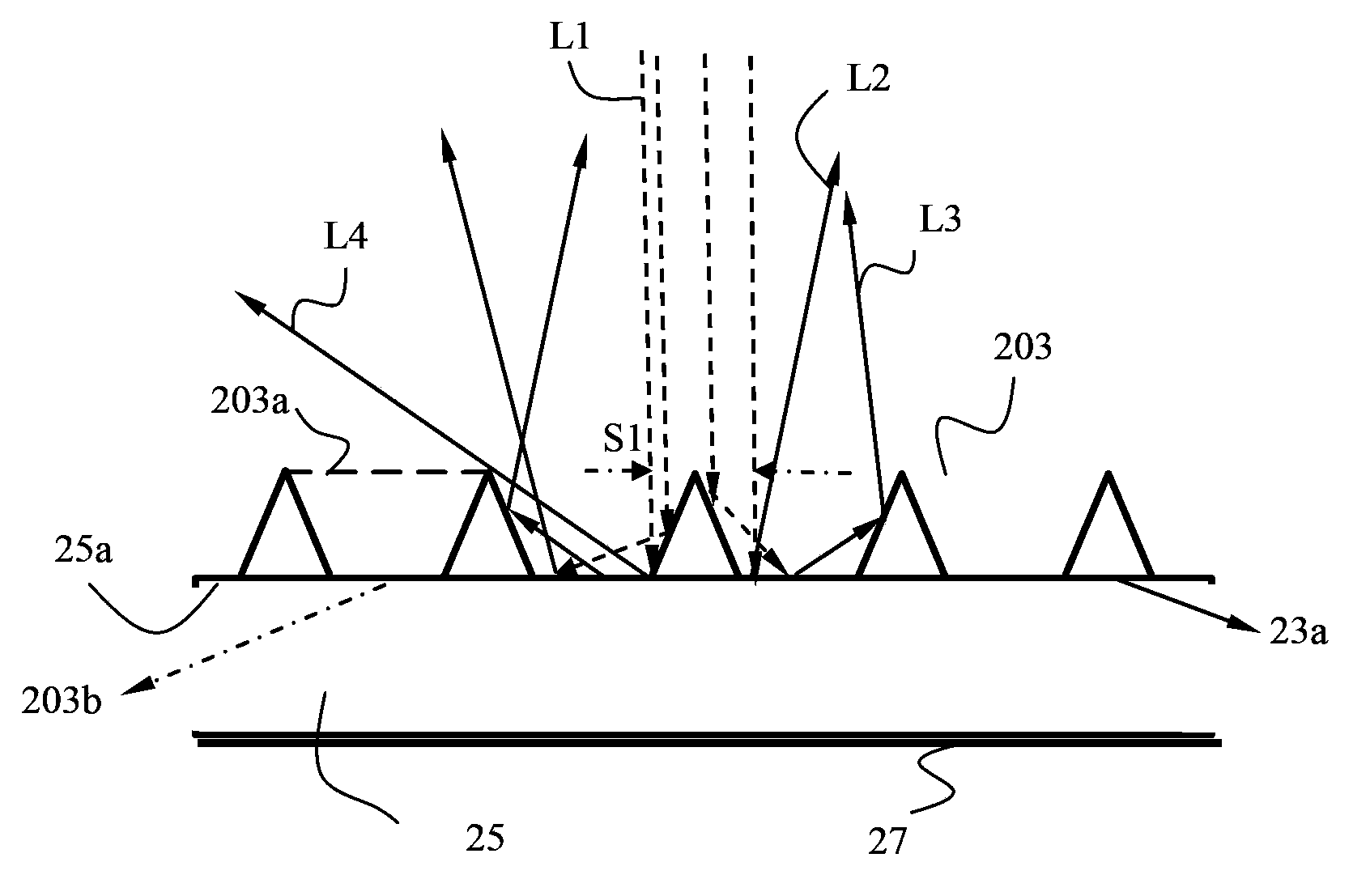

[0024] see Figure 2A , Figure 2B and Figure 2C , Figure 2A is a schematic structural view of an embodiment of the light-emitting device of the present invention, Figure 2B yes Figure 2A The schematic diagram of the local light path structure in the light-emitting device shown, Figure 2C yes Figure 2A Top view of the microstructure layer in the light-emitting device shown. . The light emitting device 200 includes an excitation light source 21 and a wavelength conversion device 22 , wherein the wavelength conversion device 22 includes a microstructure layer 23 , a wavelength conversion layer 25 and a reflective layer 27 .

[0025] The microstructure layer 23 includes a microstructure array 23a. Each microstructure 203 in the microstructure array 23a is in the shape of a through hole, and the area of the upper opening 203a of each microstructure 203 is larger than the area of the lower opening 203b, wherein the upper opening 203a of each microstructure is loca...

Embodiment 2

[0045] see Figure 3A and Figure 3B , Figure 3A is a schematic structural view of an embodiment of the light-emitting device of the present invention, Figure 3B yes Figure 3A Top view of the wavelength conversion device in the light emitting device shown. The light emitting device 300 includes an excitation light source 31 and a wavelength conversion device 32 , wherein the wavelength conversion device 32 includes a microstructure layer 33 , a wavelength conversion layer 35 and a reflective layer 37 .

[0046] The differences between this embodiment and Embodiment 1 include:

[0047] The light emitting device 300 further includes a base 34 on which the microstructure layer 33 is disposed, so that the lower openings of the microstructures 303 in the microstructure layer 33 are attached to the base. Correspondingly, the reflective layer 37 includes a plurality of sub-reflective layers 37a, wherein each sub-reflective layer 37a is respectively disposed on the substrate a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com