Buck power converter

A power converter and voltage technology, applied in the direction of output power conversion devices, instruments, electrical components, etc., can solve problems such as noise and ringing, and achieve the effect of reducing noise and ringing phenomenon.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

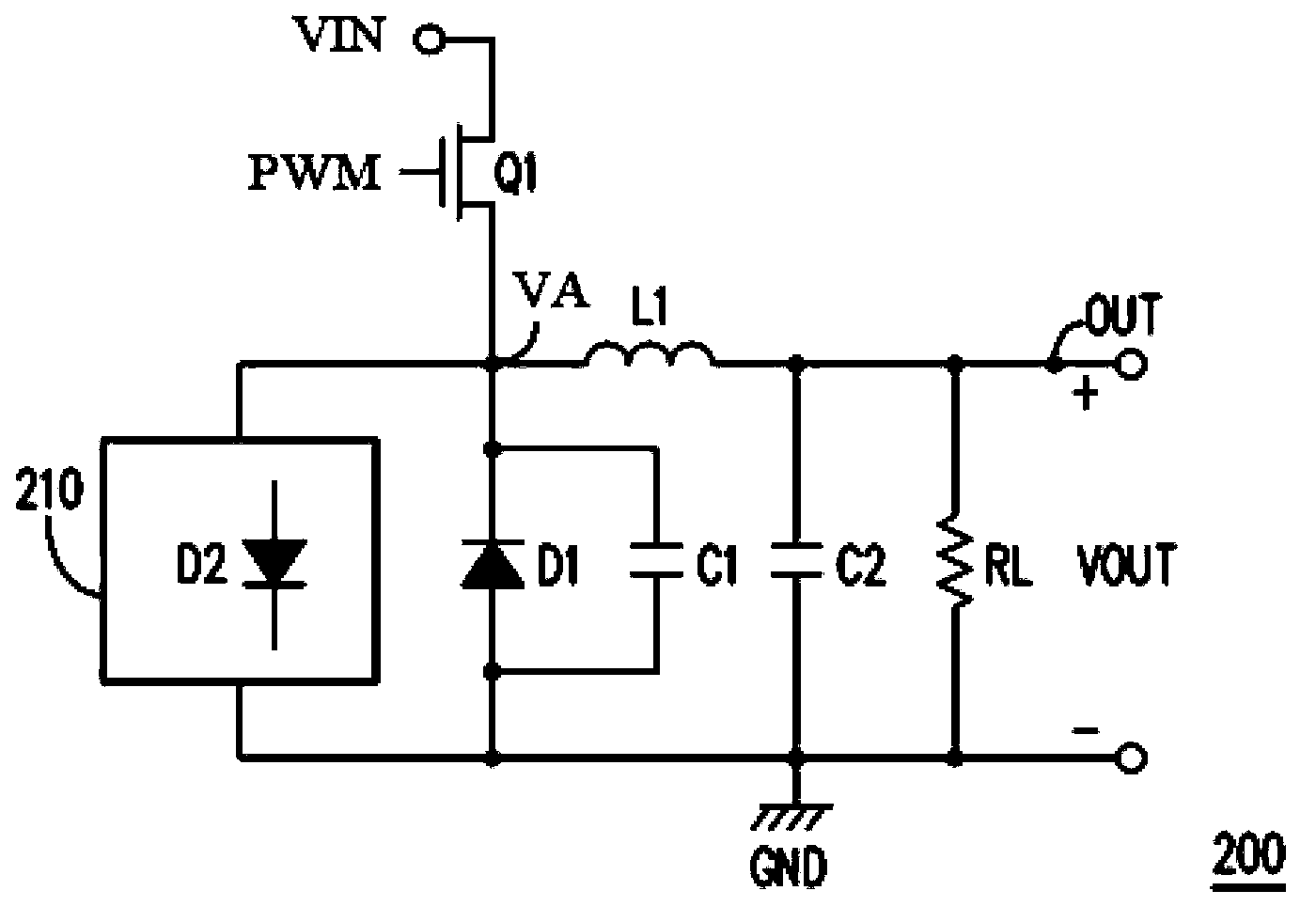

[0039] Please refer to the following figure 2 , figure 2 is a schematic diagram of a step-down power converter 200 according to an embodiment of the present invention. The buck power converter 200 includes a power transistor Q1 , an inductor L1 , a diode D1 and an anti-ringing circuit 210 . The power transistor Q1 has a first terminal (such as a source), a second terminal (such as a drain) and a control terminal (such as a gate), and its first terminal receives an input voltage VIN, and its control terminal receives a pulse width modulation signal PWM. The transistor Q1 is turned on or off according to the pulse width modulation signal PWM. The second terminal of the power transistor Q1 is coupled to the inductor L1, and the other terminal of the inductor L1 is coupled to the output terminal OUT of the step-down power converter 200 to generate the output voltage VOUT.

[0040] The diode D1 is connected in series between the second terminal of the power transistor Q1 and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com