LED chip mounting feeding device

A technology of LED chip and feeding device

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

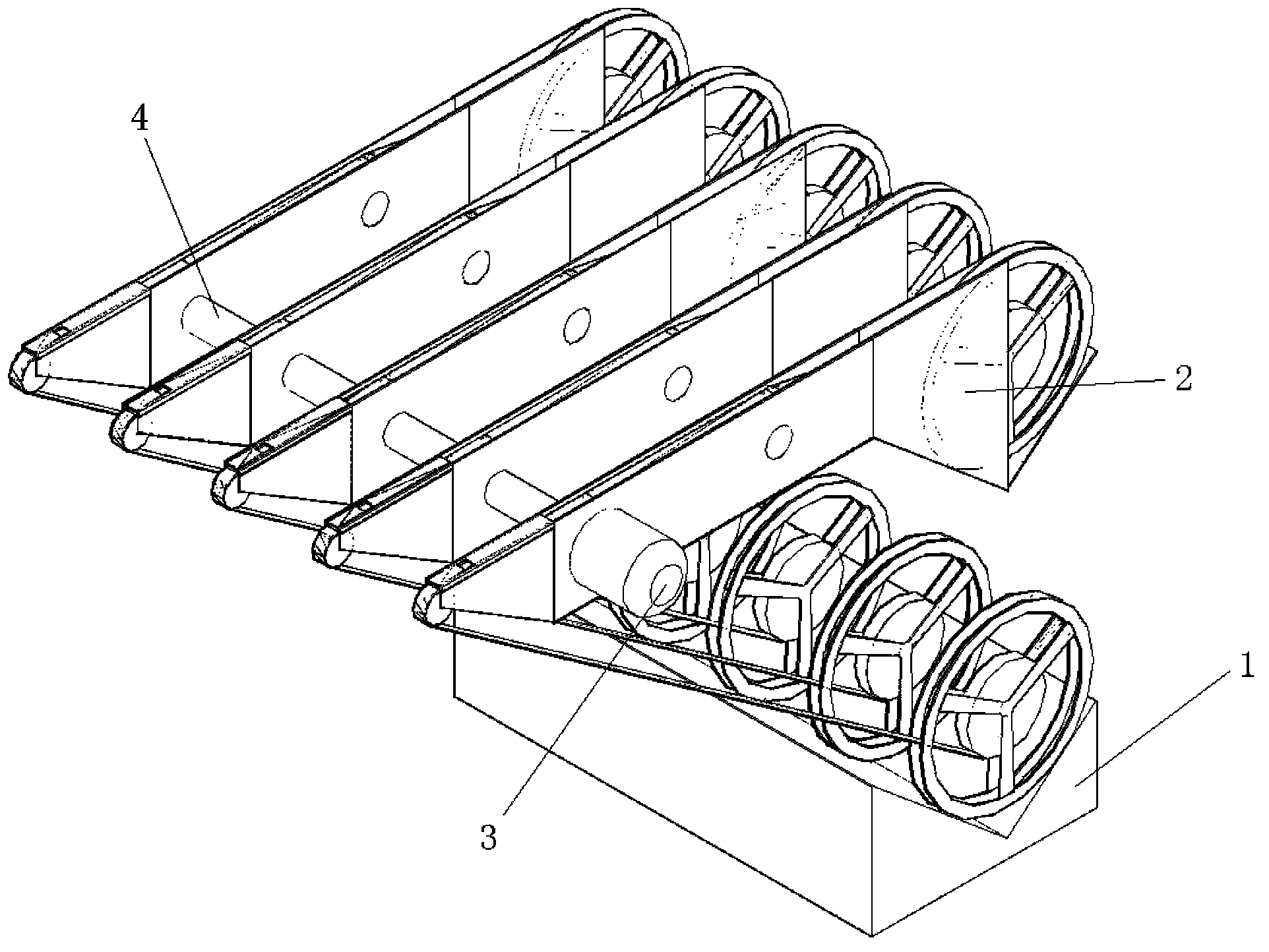

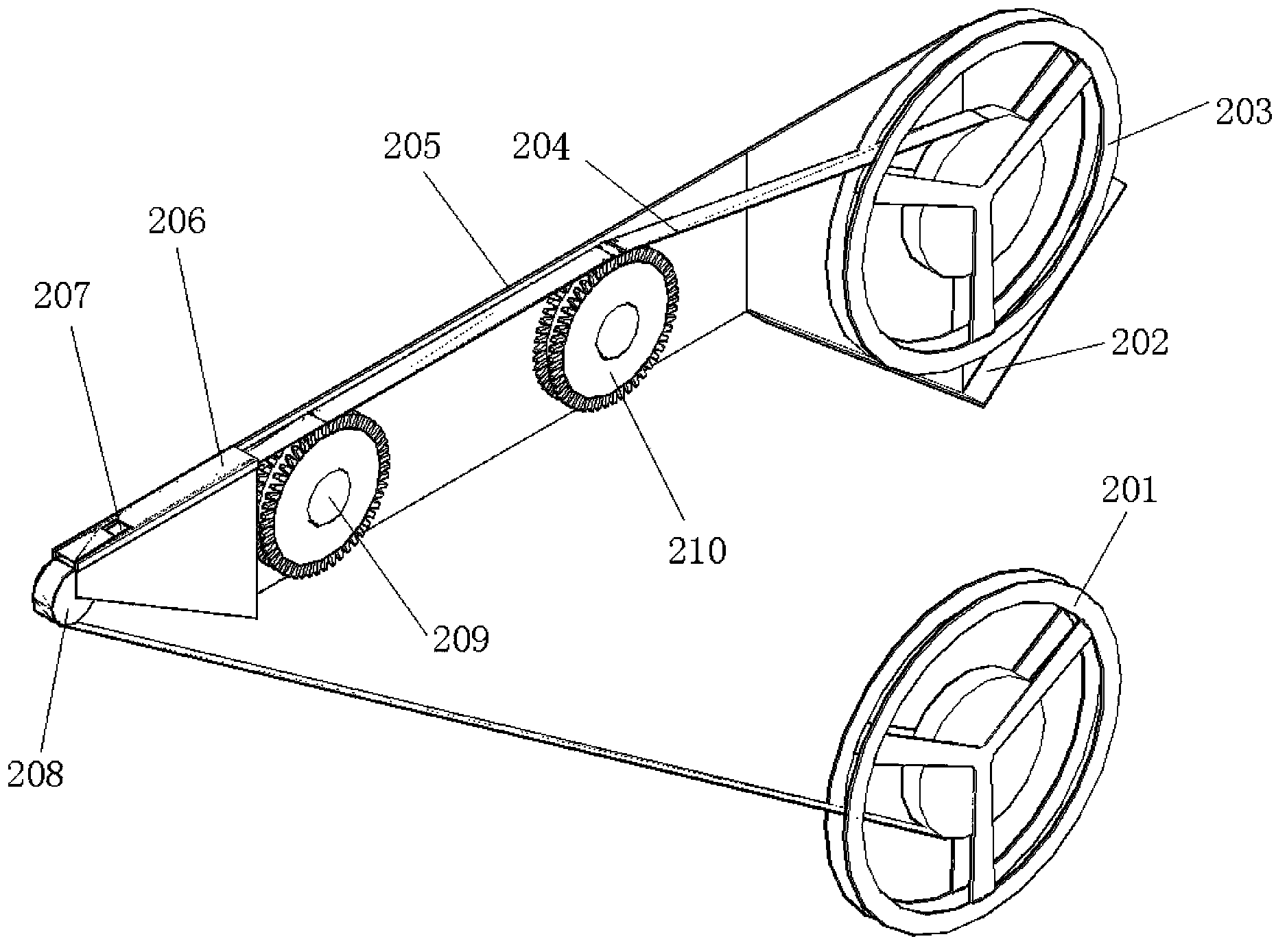

[0020] Such as figure 1 and figure 2 As shown, the present invention includes a feeding unit 2, a return rack 1, a connecting shaft 4 and a drive motor 3, the number of the feeding unit 2 is multiple and a plurality of feeding units 2 are connected by a connecting shaft 4, and the driving motor 3 is fixedly installed on one end of the connecting shaft 4 and is used to drive the connecting shaft 4 to rotate; the feeding unit 2 includes a storage part, a feeding part, a picking part and a feeding part, and the storage part includes a storage rack 202 and a setting The storage roller 203 in the storage rack 202, the bottom of the storage rack 202 is V-shaped, the LED feed belt 204 is wound on the storage roller 203, and the feeding part includes a material connected to the storage rack 202. The feeding frame 205 and the driving sprocket 209 and the feeding sprocket 210 installed on the side wall of the feeding frame 205, the feeding sprocket 210 is rotatably mounted on the cent...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com