Temperature measurement in a cooking vessel

A technology of cooking containers and sensors, applied in the field of induction heating devices, can solve problems such as difficulties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

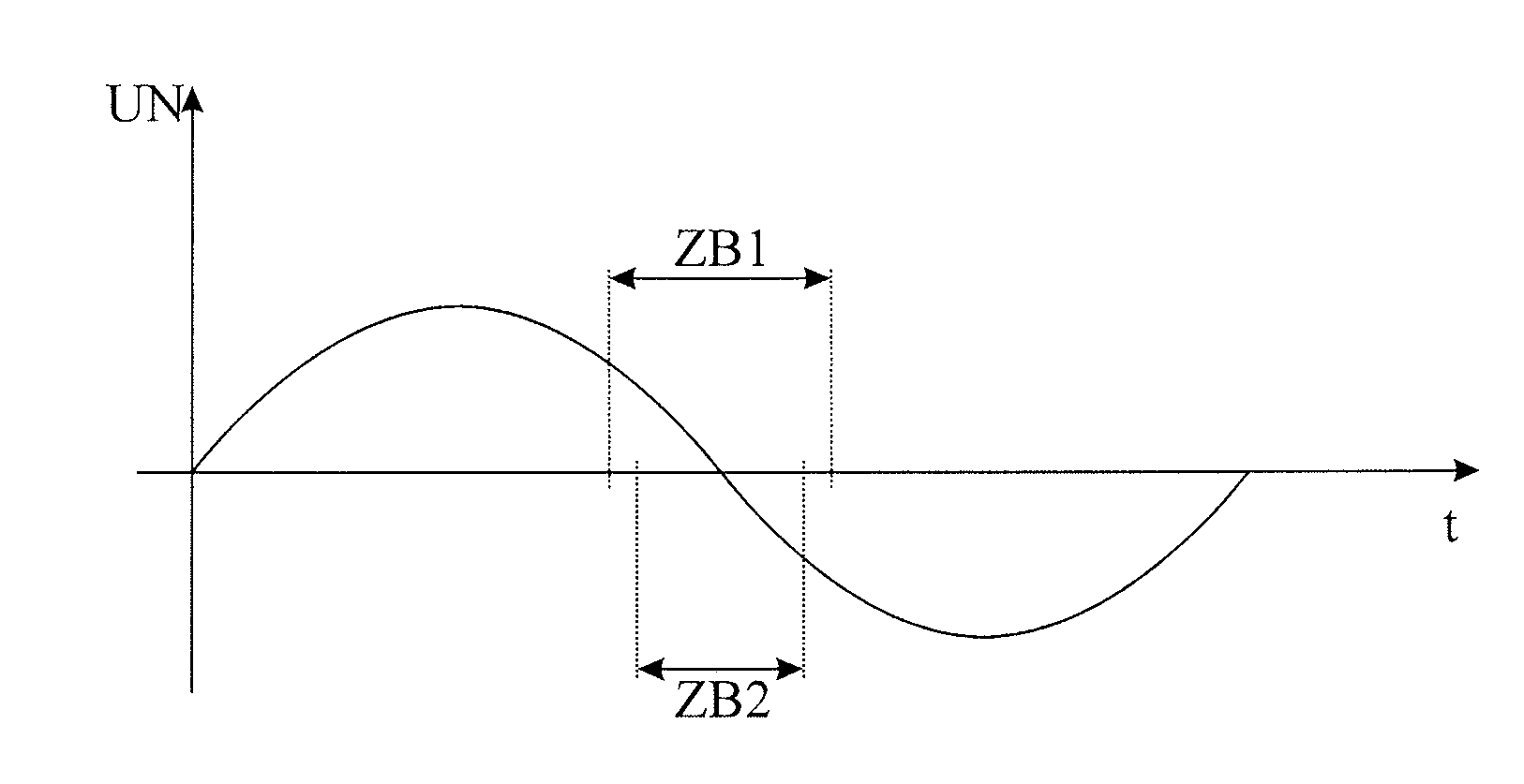

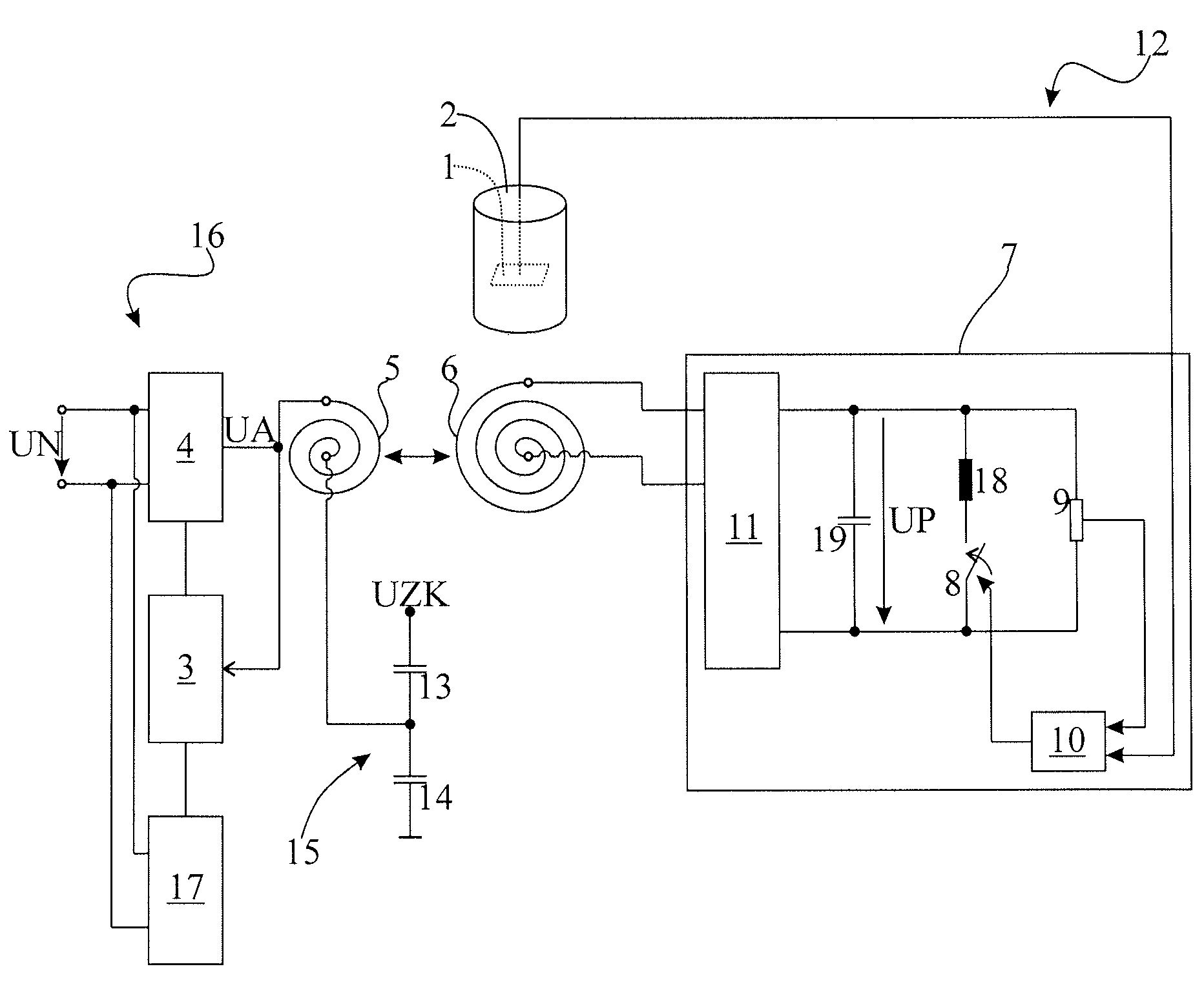

[0023] figure 1 A system with an inductively heatable cooking vessel 2 with a sensor device 12 and an induction heating device 16 is shown.

[0024] The sensor device 12 has a temperature sensor 1 in the form of a conventional NTC temperature sensor for the temperature of the cooked food detected by heating the cooking vessel 2 , wherein the sensor is for example in the form of a core temperature sensor (Kerntemperaturfühler). The form is arranged in the cooking container 2—for example, in the side wall of the cooking container 2 or in a cavity not shown at the bottom of the cooking container 2 or on a flexible conveying line that can move freely in the cooking container 2 an antenna in the form of a coil 6 which can be inductively or magnetically coupled to the induction heating coil 5 of the induction heating device; an energy supply device in the form of a rectifier—for example a bridge rectifier—11, which is connected to the coil 6 Output voltage rectification, wherein th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com