Preparation method for green tea

A processing method and green tea technology, which are applied in the green tea processing field, can solve the problems that the leaf bottom is not green and bright, the taste is not fresh and mellow and refreshing, and the finished green tea has a weak aroma, and achieves the promotion of full transformation and polymerization, and the shape of the tea leaves is tight and straight. even effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

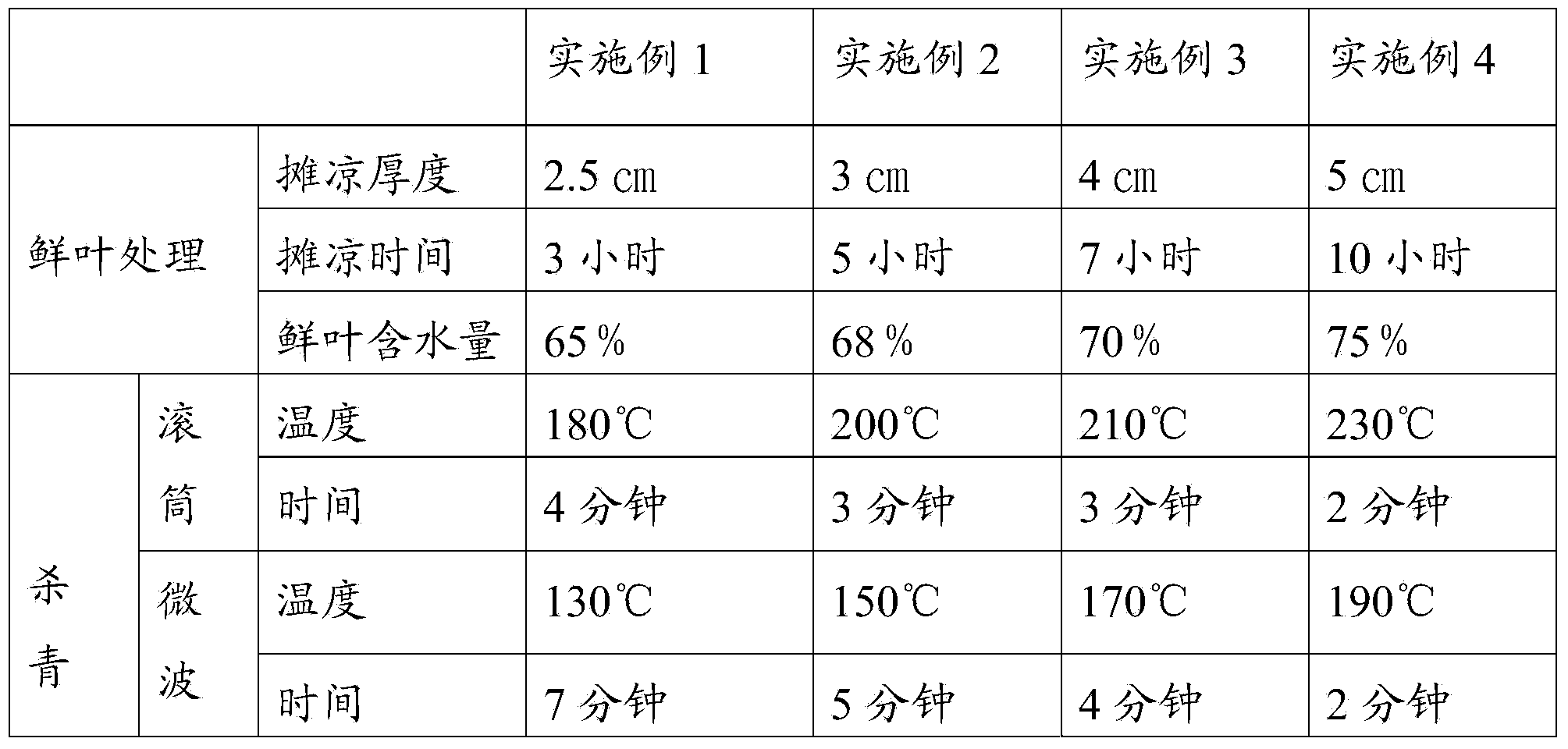

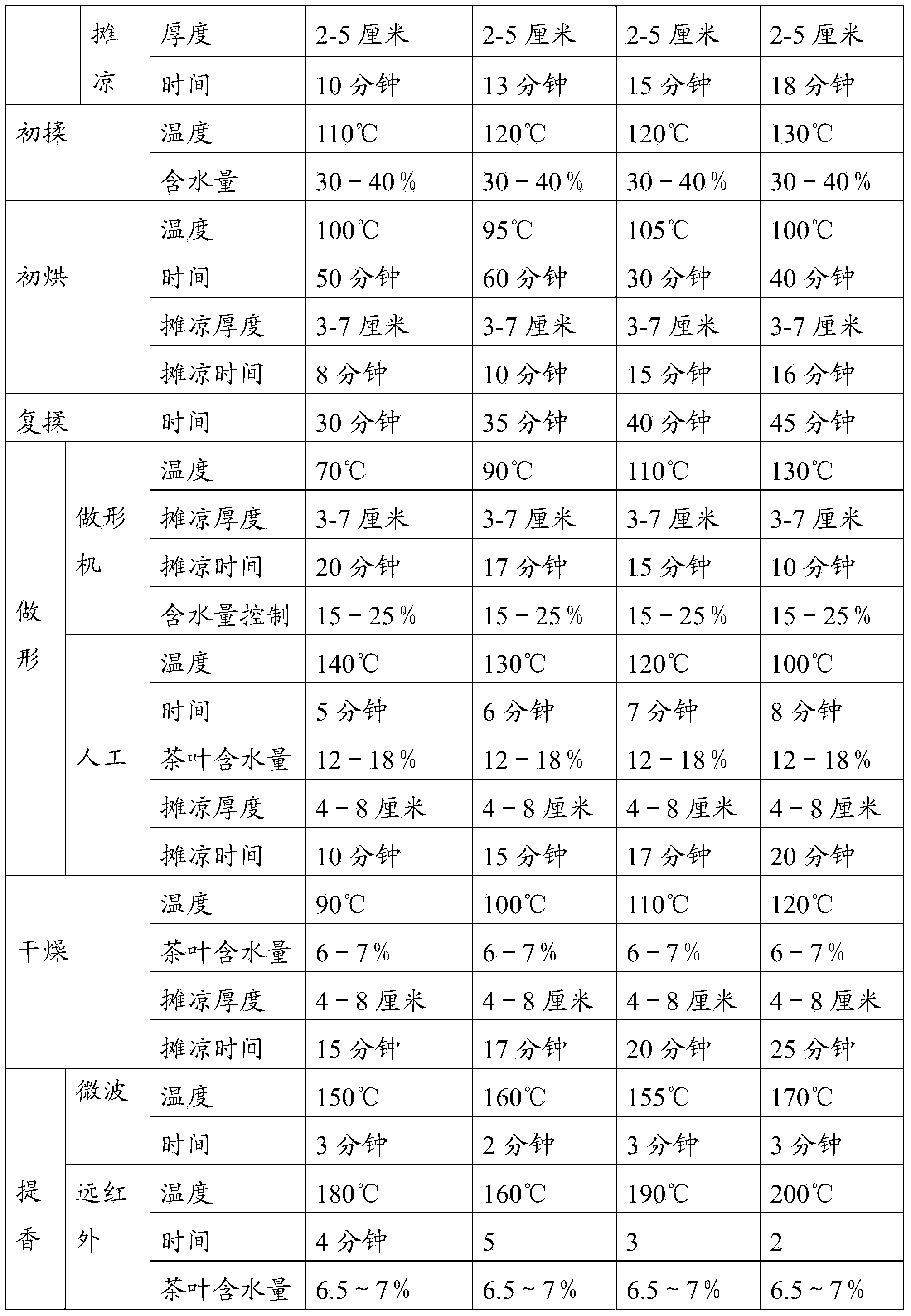

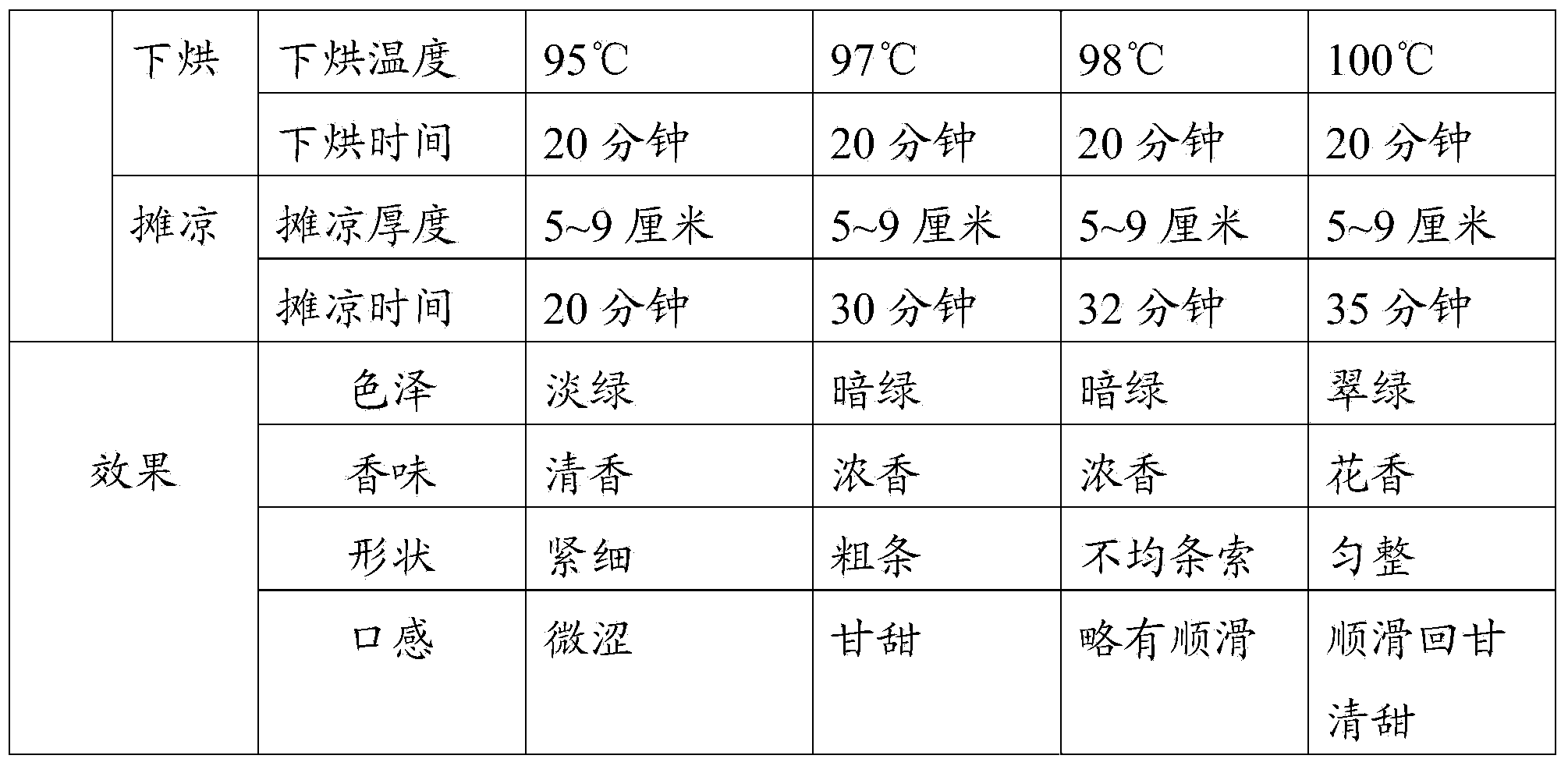

[0015] The green tea processing method of the present invention comprises the steps of fresh leaf treatment, green removal, initial kneading, initial drying, re-kneading, shaping, drying and aroma enhancing.

[0016] The fresh leaf treatment step is as follows: spread the fresh leaves to cool, the thickness of the spread is 2.5-5 cm, the cool time is 3-10 hours, and the water content of the fresh leaves is controlled at 65-75%.

[0017] The de-enzyming step is: first and then use a continuous drum de-enzyming machine and a microwave de-enzyming machine for de-enzyming. When using a continuous-type de-enzyming machine, the temperature is 180-230° C., and the time is 2-4 minutes. When the leaves are soft, When there is still luster and a little green gas, enter the microwave killing machine to complete the greening. The temperature of the microwave curing machine is 130-190 ° C, and the time is 2-7 minutes. Dissipated, the leaves emerge when the fragrance escapes, and the wind b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com