Method for improving clean coal yield through adding underflow pump to sludge pit bucket elevator

A technology of bucket elevator and clean coal is applied in the operation field of scooping bucket elevator for coarse slime classification. , the effect of eliminating the coal yield and eliminating the amount of washing

Inactive Publication Date: 2014-06-11

BAOSTEEL GROUP XINJIANG BAYI IRON & STEEL

View PDF4 Cites 3 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0002] At present, the classification of coarse coal slime water mainly adopts several methods such as pit bucket elevator, pyramid pool, grading screen, grading sieve + conical pool + slime cyclone, grading screen + inclined tube pool + high frequency sieve; The coal preparation system uses pit bucket elevators to classify coarse coal slime water. Due to the large content of argillaceous shale in raw coal, raw coal becomes difficult to select in terms of coal selection, and materials with a particle size of less than 0.5mm increase from 20% to 30%, when water sees, it is easy to muddy, which leads to arching around the pit during the washing process. In severe cases, only the rotating part of the bucket elevator remains, and all other parts accumulate slime, which seriously reduces the effective settlement area of the pit. ;Because the slime water does not have time to settle, the coarse slime runs seriously, and the flotation operation is difficult, resulting in low ash content in the tailing coal press filter and loss of clean coal; even the deposited coal slime collapses and presses the bucket elevator, making normal production impossible; The four walls are seriously hanged and arched, which leads to coarse coal slime running thick, clean coal loss and solving the technical problems that cannot be produced normally are the entry points of the present invention.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment

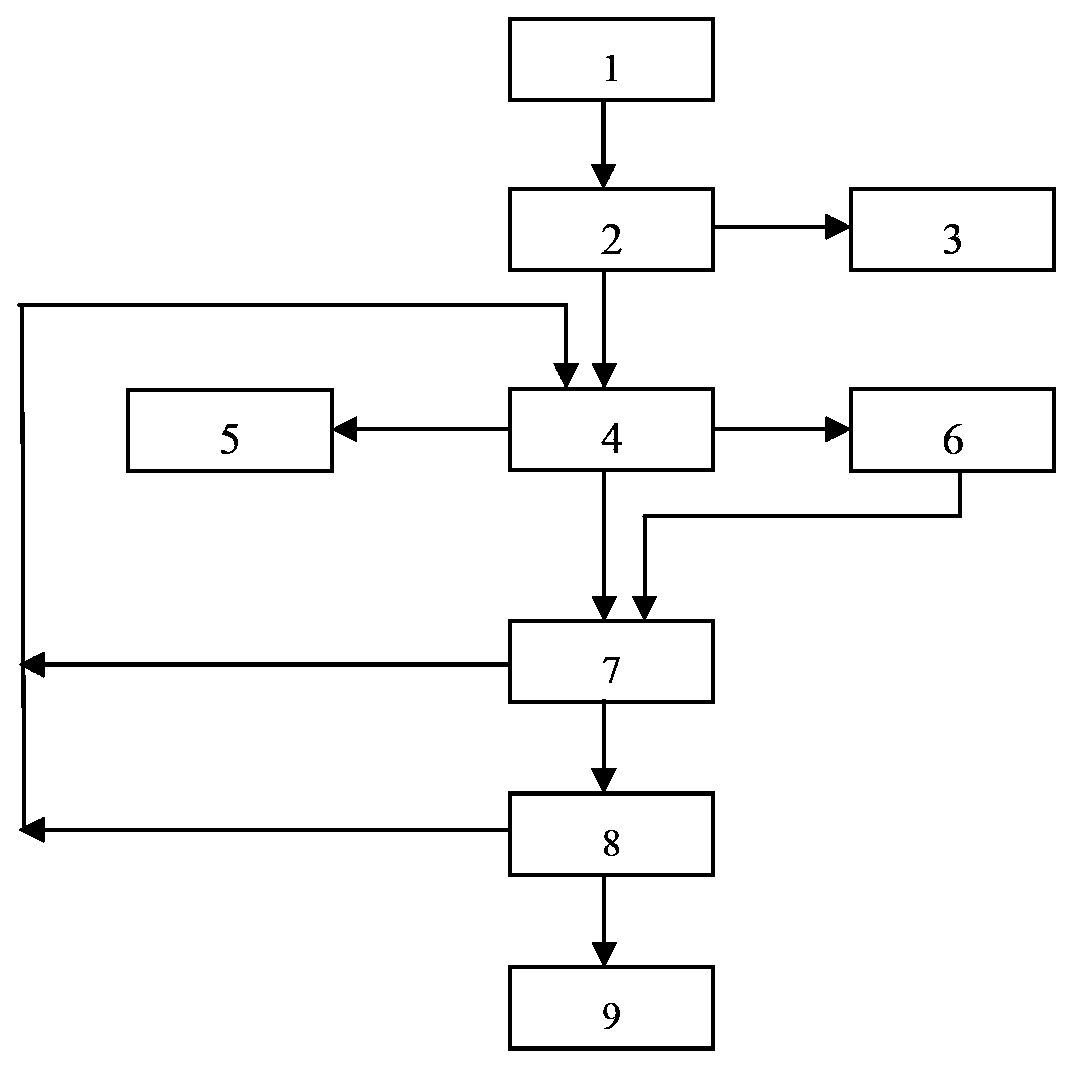

[0017] Process flow:

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

Login to View More

Abstract

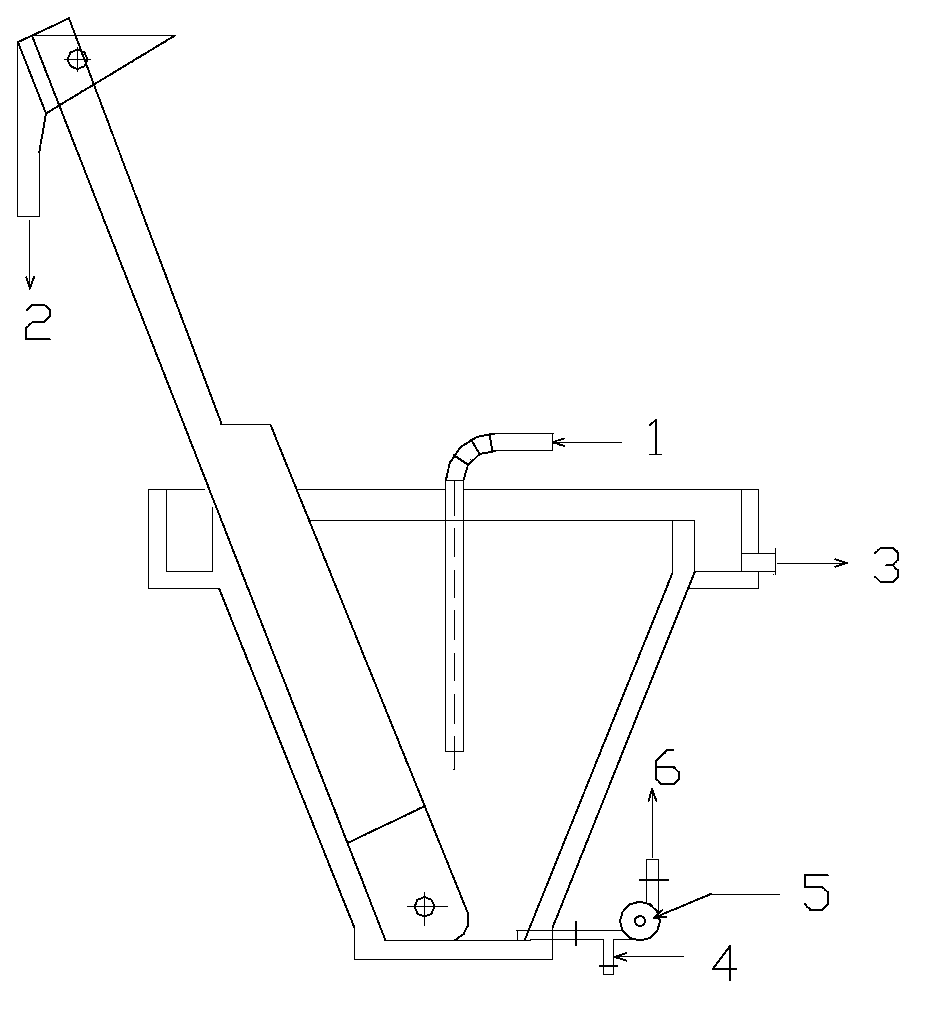

The invention provides a method for improving the clean coal yield through adding an underflow pump to a sludge pit bucket elevator. The method comprises enabling washing raw coal to enter into a wash box through a buffer cabin to be sorted, wherein the particle size of the washing raw coal is 1 to 50 mm; obtaining clean coal blocks by sorting coal through overflow of the wash box and a dewatering screen; enabling screened materials to enter into the bucket elevator, dredging the materials through the bucket elevator to enter into a desliming screen to be deslimed and enabling the materials on the desliming screen to enter into a centrifugal water extractor, wherein the materials which are dewatered through the centrifugal water extractor are slack clean coal; enabling the coal slime and the centrifugal fluid which are screened through the desliming screen to automatically flow back to a sludge pit; pumping overflow objects of the sludge pit through a pump into a flotation machine for coal slime sorting; connecting a feeding inlet pipe into the sludge pit of the bucket elevator to be communicated with a clean coal outlet of the bucket elevator; forming an overflow pool at the outer edge of an upper opening of the bucket elevator to be communicated with an overflow object outlet; enabling the bottom of the sludge pit of the bucket elevator to be connected with a slurry pump and arranging a discharge valve at an inlet of the slurry pump to be communicated with the bottom of the sludge pit, wherein an outlet pipe of the slurry pump is connected with a screen pipe of the desliming screen.

Description

technical field [0001] The invention relates to the field of coal preparation, and is especially suitable for washing large amounts of argillaceous shale and adopting a pit bucket elevator to classify coarse coal slime. The device and method thereof can effectively increase the yield of clean coal. Background technique [0002] At present, the classification of coarse coal slime water mainly adopts several methods such as pit bucket elevator, pyramid pool, grading screen, grading sieve + conical pool + slime cyclone, grading screen + inclined tube pool + high frequency sieve; The coal preparation system uses pit bucket elevators for coarse coal slime water classification. Due to the large content of argillaceous shale in the raw coal, the raw coal becomes difficult to select in terms of coal selection, and the material with a particle size of less than 0.5mm increases from 20% to 30%, it is easy to become muddy when it sees water, which leads to arching around the fishing pi...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): B03B7/00

Inventor 张常明

Owner BAOSTEEL GROUP XINJIANG BAYI IRON & STEEL

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Patsnap Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com