Grid stirring flocculation reaction device

A technology of reaction equipment and grid flocculation, which is applied in the direction of flocculation/sedimentation water/sewage treatment, etc., can solve the problems of heavy maintenance workload of mechanical flocculation tanks, large dependence on external environmental factors, difficult process control, etc., so as not to block the mesh , The effect of shortening the flocculation time and improving the water flow conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

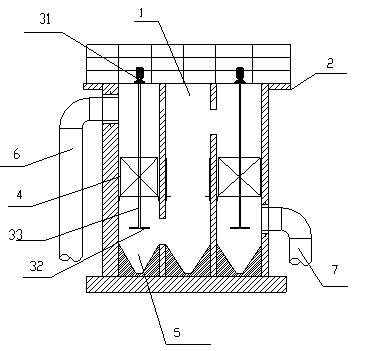

[0011] The present invention will be described in detail below in conjunction with the accompanying drawings.

[0012] like figure 1 As shown, a grid stirring flocculation reaction equipment, the grid flocculation reaction equipment is formed by a number of shafts 1 connected in series, the top of the shaft 1 is provided with a corridor type cover plate 2, and every 1-3 rows of vertical shafts 1 are provided in the straight ditch. There is a mixer and several layers of grid packing 4, which increases the particle collision in the raw water under the constant stirring and grid hydraulic action, provides more favorable conditions for flocculation, and shortens the flocculation time at the same time. Holes are staggered on the wall and the bottom to make the water flow up and down until the outlet. The mixer is composed of a stirring motor 31, a stirring shaft 33 and a stirring impeller 32. The stirring motor 31 is set on the corridor-type cover plate 2 on the top and passes thro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com