Sterilizing rubber roller

A rubber roller and rubber technology, which is applied in the field of rubber products, can solve the problems of affecting use and dirty surfaces, and achieves the effects of convenient storage, long antibacterial life and less harm

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

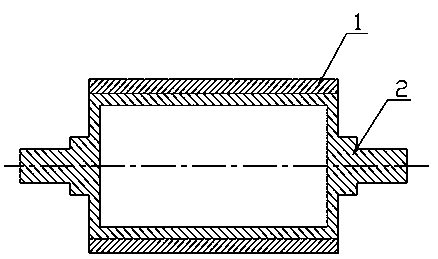

[0014] See figure 1 , Provide a sterilization rubber roller, comprising a roller 1 and a roller core 2, the roller 1 is wrapped on the outer surface of the roller core 2, the surface roughness of the roller 1 is 12um, the roller The material of 1 is rubber, and the composition of the rubber is: 100 parts by mass of chlorobutyl rubber, 7 parts of stearic acid, 6 parts of magnesium oxide, 4 parts of N,N'-diphenylguanidine, and oxidation 2 parts of zinc, 1.2 parts of ethoxylates, 1.6 parts of triazole fungicides.

Embodiment 2

[0016] A bactericidal rubber roller is provided, which includes a roller and a roller core, the roller is wrapped on the outer surface of the roller core, the surface of the roller has a roughness of 4um, and the material of the roller is rubber. The composition of the rubber is: in parts by mass, 100 parts of chlorinated butyl rubber, 5 parts of stearic acid, 4 parts of magnesium oxide, 7 parts of N,N'-diphenylguanidine, 3 parts of zinc oxide, and paraben 0.7 parts of sulfonate and 1.3 parts of triazole fungicide are made by conventional manufacturing process.

Embodiment 3

[0018] A sterile rubber roller is provided, which includes a roller and a roller core, the roller is wrapped on the outer surface of the roller core, the surface of the roller has a roughness of 9um, and the material of the roller is rubber. The composition of the rubber is: in parts by mass, 100 parts of chlorinated butyl rubber, 6 parts of stearic acid, 5 parts of magnesium oxide, 6 parts of N,N'-diphenylguanidine, 2.6 parts of zinc oxide, and pyriphenol 1 part of sulfonate and 1.4 parts of triazole bactericide are made by conventional manufacturing process.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Roughness | aaaaa | aaaaa |

| Roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com