Full face tunnel boring machine concrete spraying device

A technology of tunnel boring machine and shotcrete, which is applied to tunnels, tunnel linings, shaft equipment, etc., can solve problems such as mismatching of tunneling efficiency, large rebound of shotcrete materials, and increased slag cleaning workload, etc. The effect of supporting progress, reducing mechanical failure, and shortening the telescopic arm of the shotcrete manipulator

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

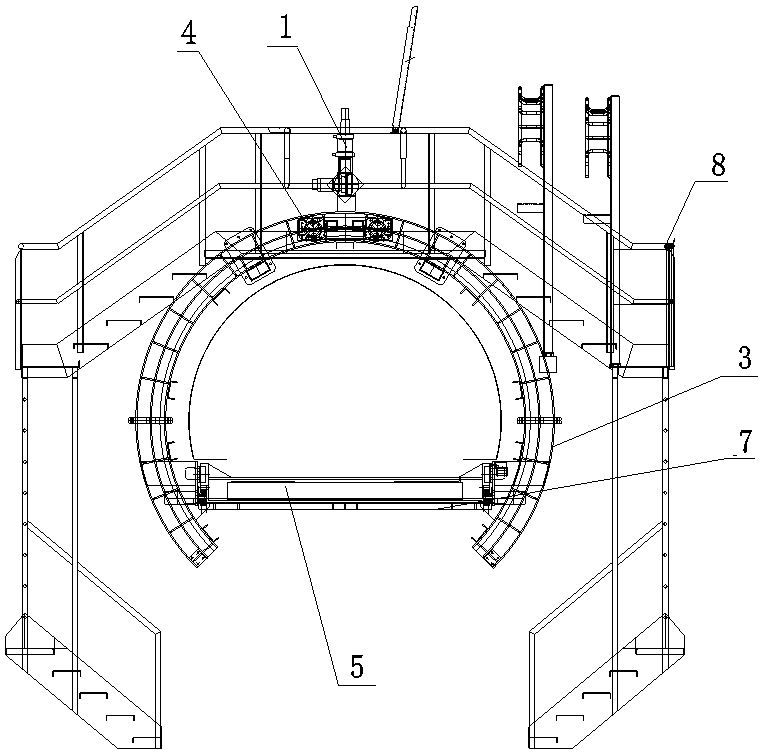

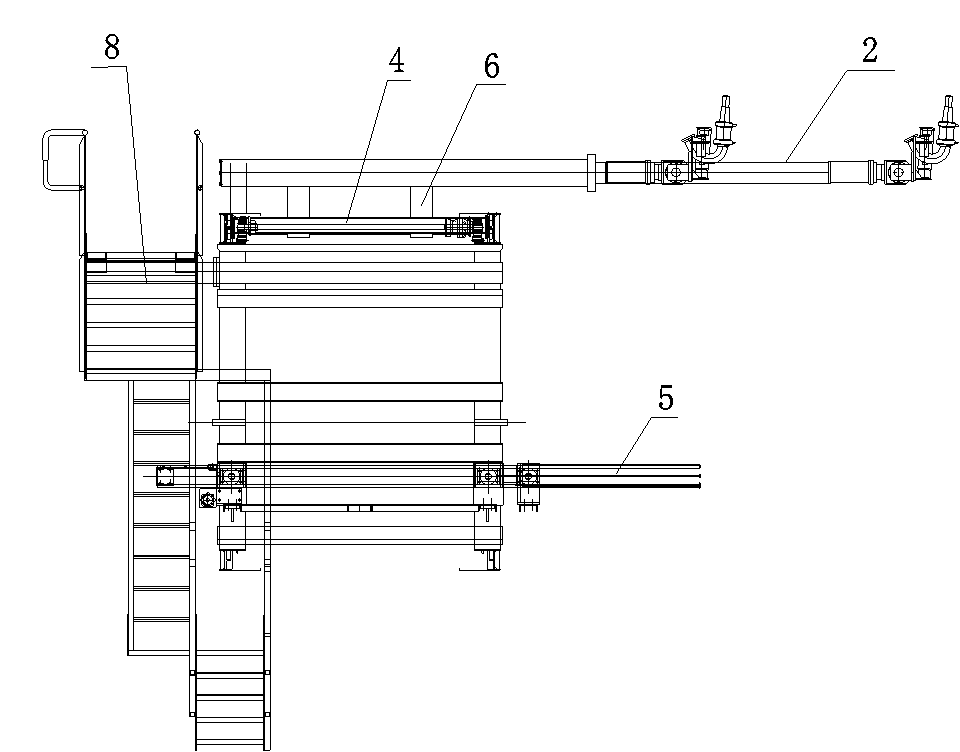

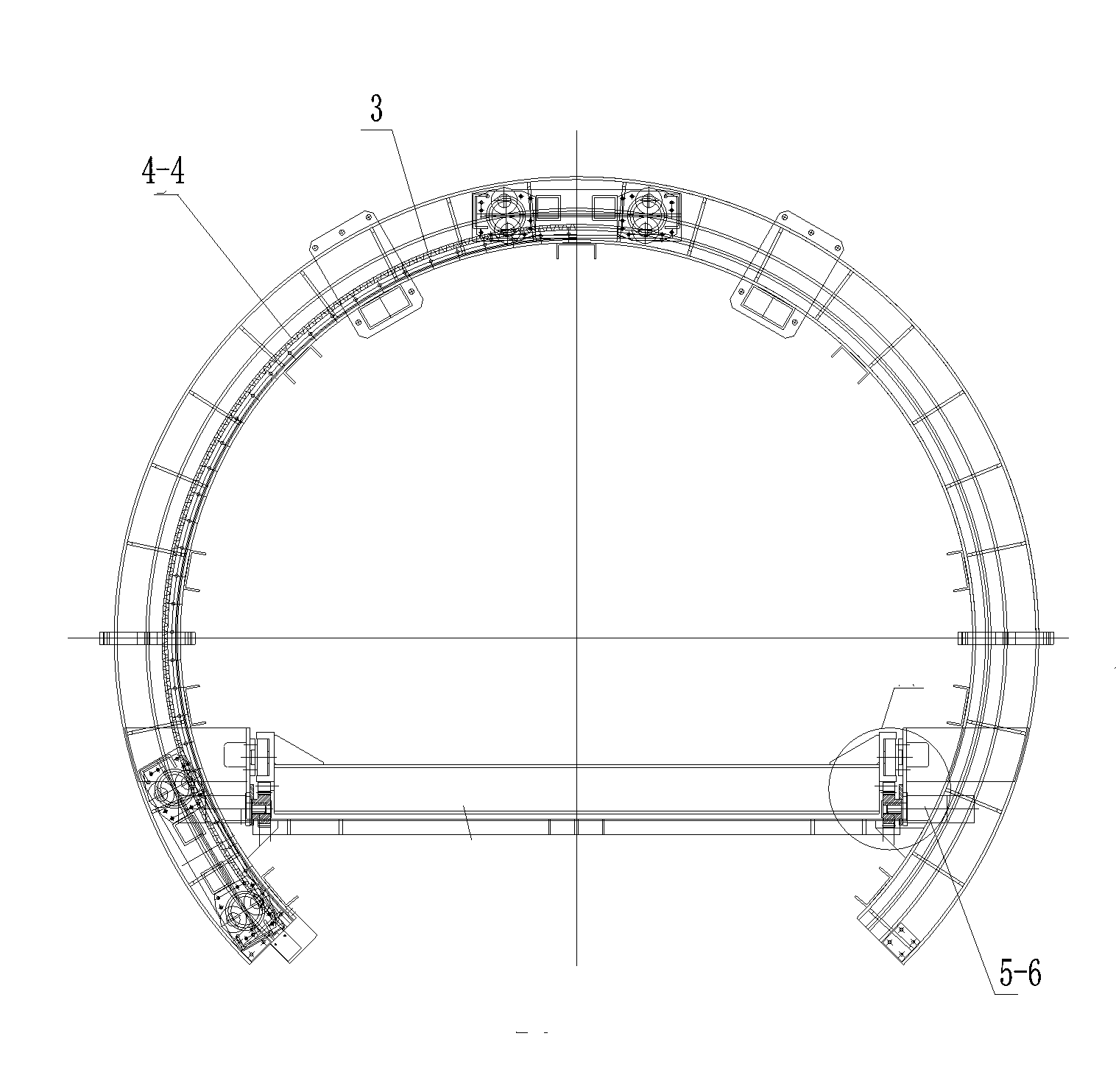

[0027] see Figure 1 to Figure 7 , in the figure, the sprayed concrete device of the full-section tunnel boring machine of the present invention includes a spraying head 1, a spraying manipulator telescopic arm assembly 2 arranged longitudinally along the tunnel, and an annular spraying carriage assembly 3, a spraying The manipulator circumferential rotation device 4 and the spraying carriage longitudinal moving device 5, the spraying head is installed on the spraying manipulator telescopic frame assembly, and the spraying manipulator telescopic frame assembly rotates circumferentially with the spraying manipulator through the connecting plate 6 The device is fixedly connected, the large ring gear contained in the circumferential rotation device of the spraying manipulator is fixedly installed on the inner side of the carriage contained in the spraying carriage assembly, and the longitudinal moving device of the spraying carriage is horizontally installed on the spraying carria...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap