A fiber grating sensor for measuring the temperature in the cavity of arf excimer laser

An excimer laser, fiber grating technology, applied in thermometers, measuring devices, measuring heat and other directions, can solve the problem that temperature sensors cannot be used in high pressure, strong corrosive environments, etc., to improve the accuracy of temperature measurement in the cavity and increase the accuracy The effect of sex, small size and light weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with specific embodiments and with reference to the accompanying drawings.

[0040] The main purpose of the present invention is to provide a sensor capable of accurately measuring the temperature in the cavity of an ArF excimer laser. Its realization mainly lies in placing a specially packaged fiber grating in the laser cavity to be tested, and obtaining the precise temperature in the cavity according to the change of the central wavelength.

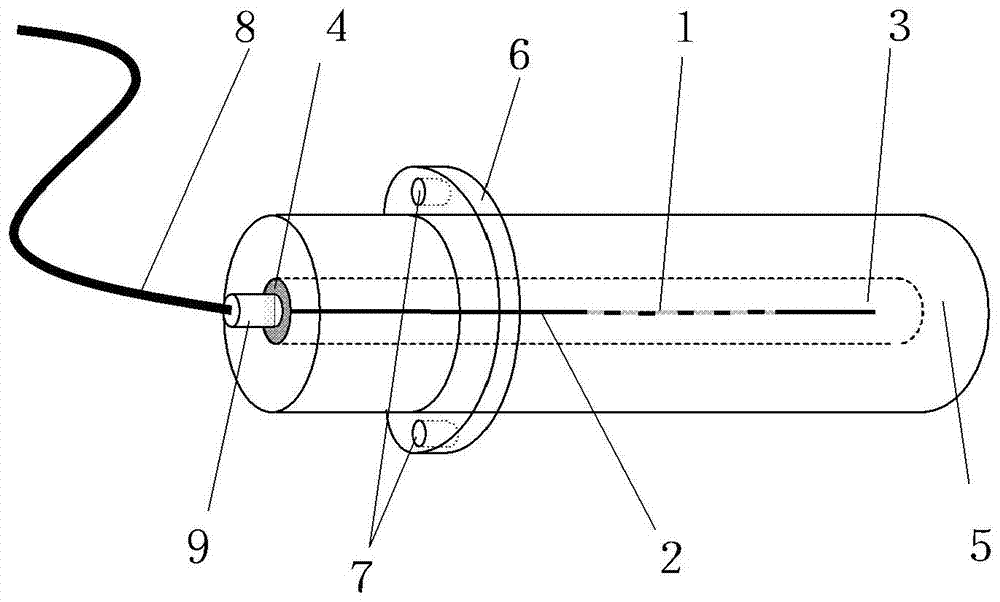

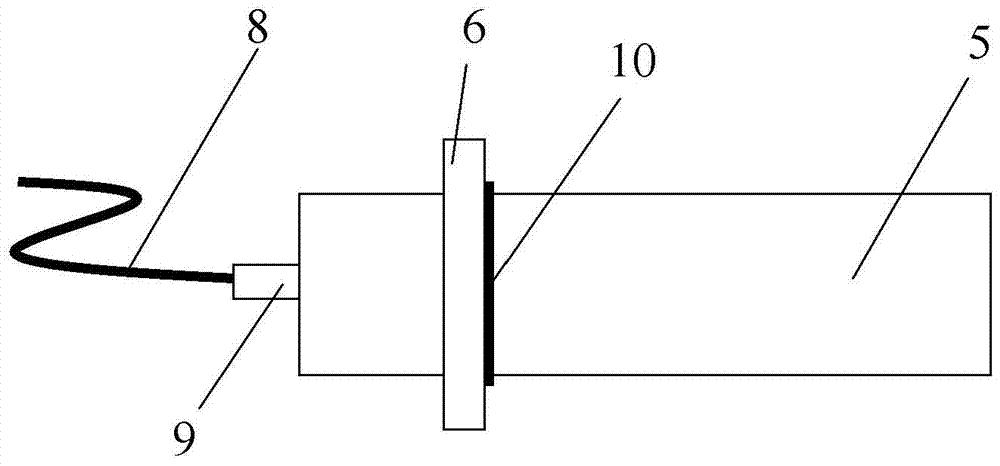

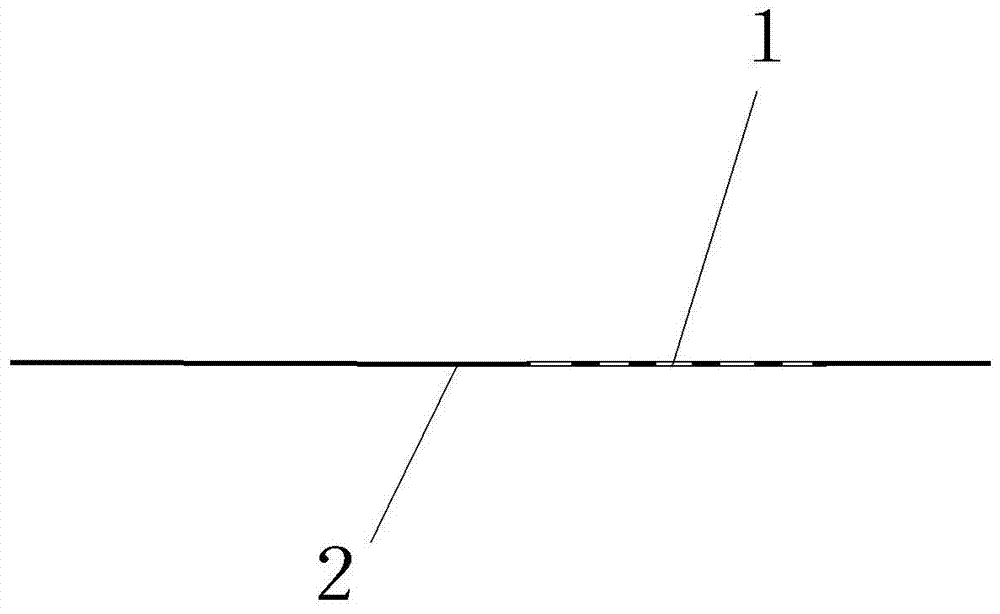

[0041] Such as figure 1 , figure 2 As shown, the present invention provides a fiber grating sensor for accurately measuring the temperature in the cavity of an ArF excimer laser, comprising: a nickel-plated stainless steel tube 5, a recoated fiber grating sensor head 1, filled with the stainless steel tube 5 Internal heat-conducting glue 3, one end of th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com