Rotary drum membrane component, membrane bioreactor and cleaning method of membrane bioreactor

A membrane bioreactor, roller membrane technology, which is applied in chemical instruments and methods, biological water/sewage treatment, membrane technology, etc. Effects of Vibration Efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The technical solution of the present invention will be described in detail below with reference to the drawings and embodiments.

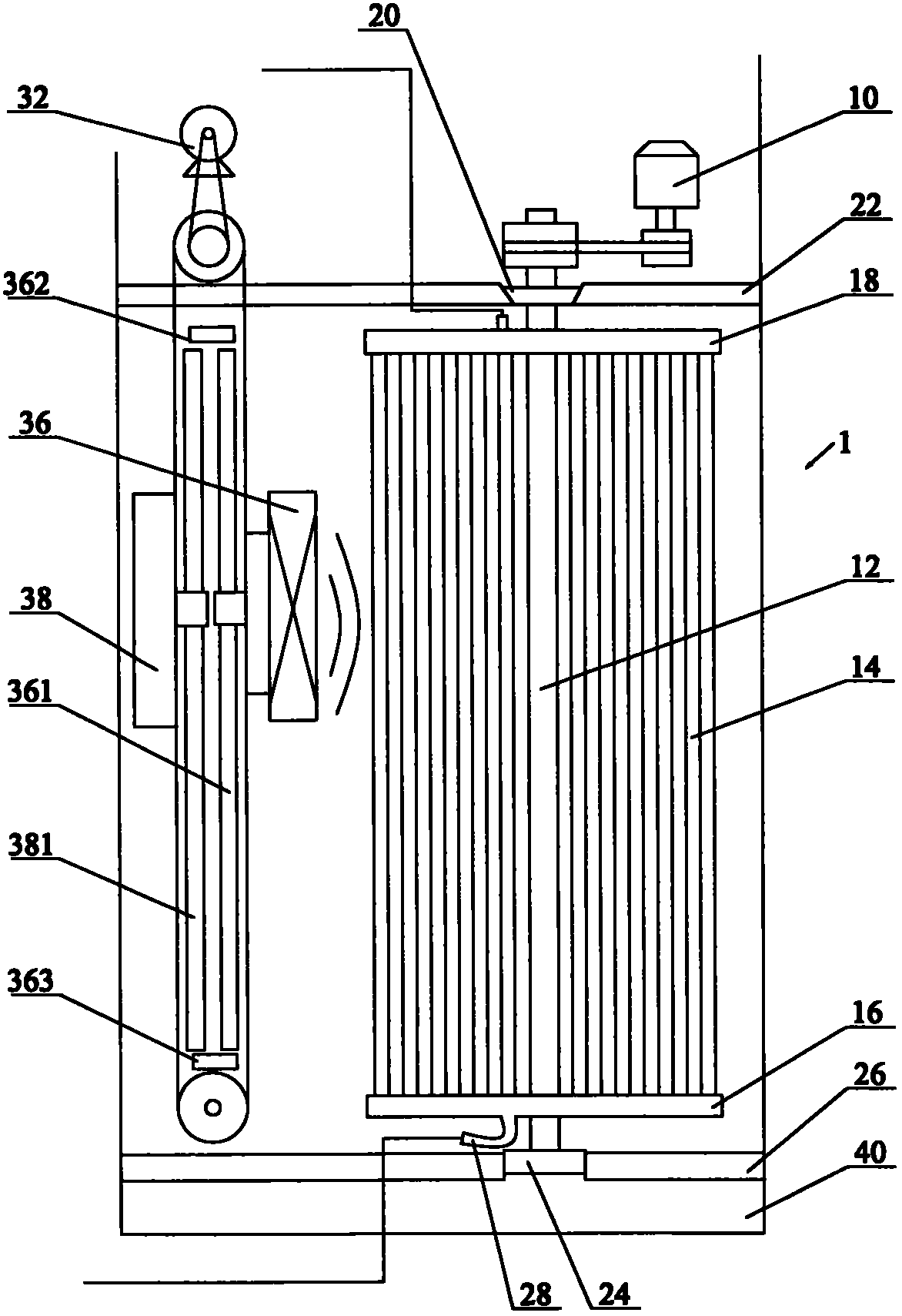

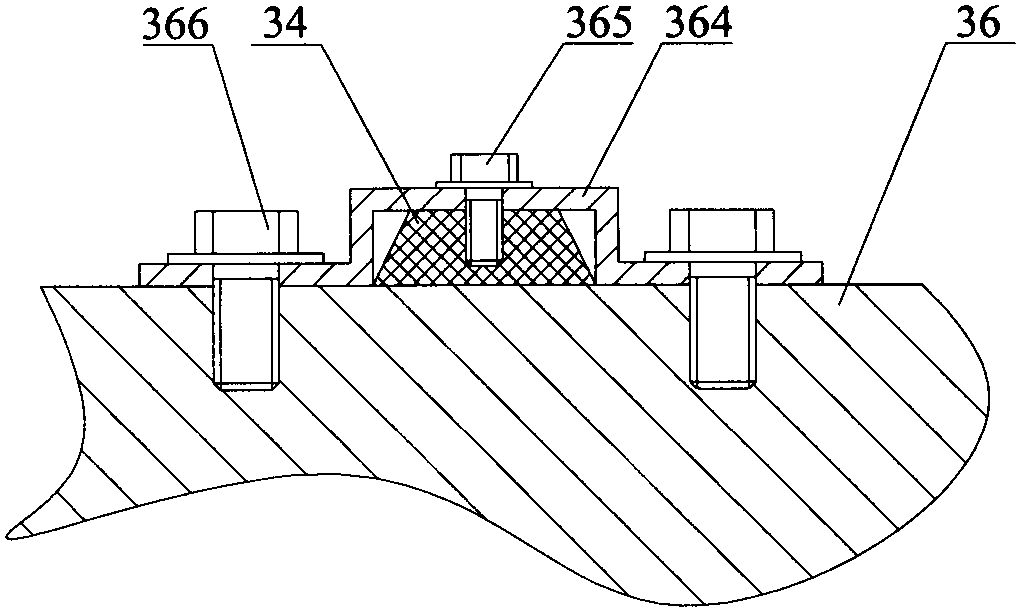

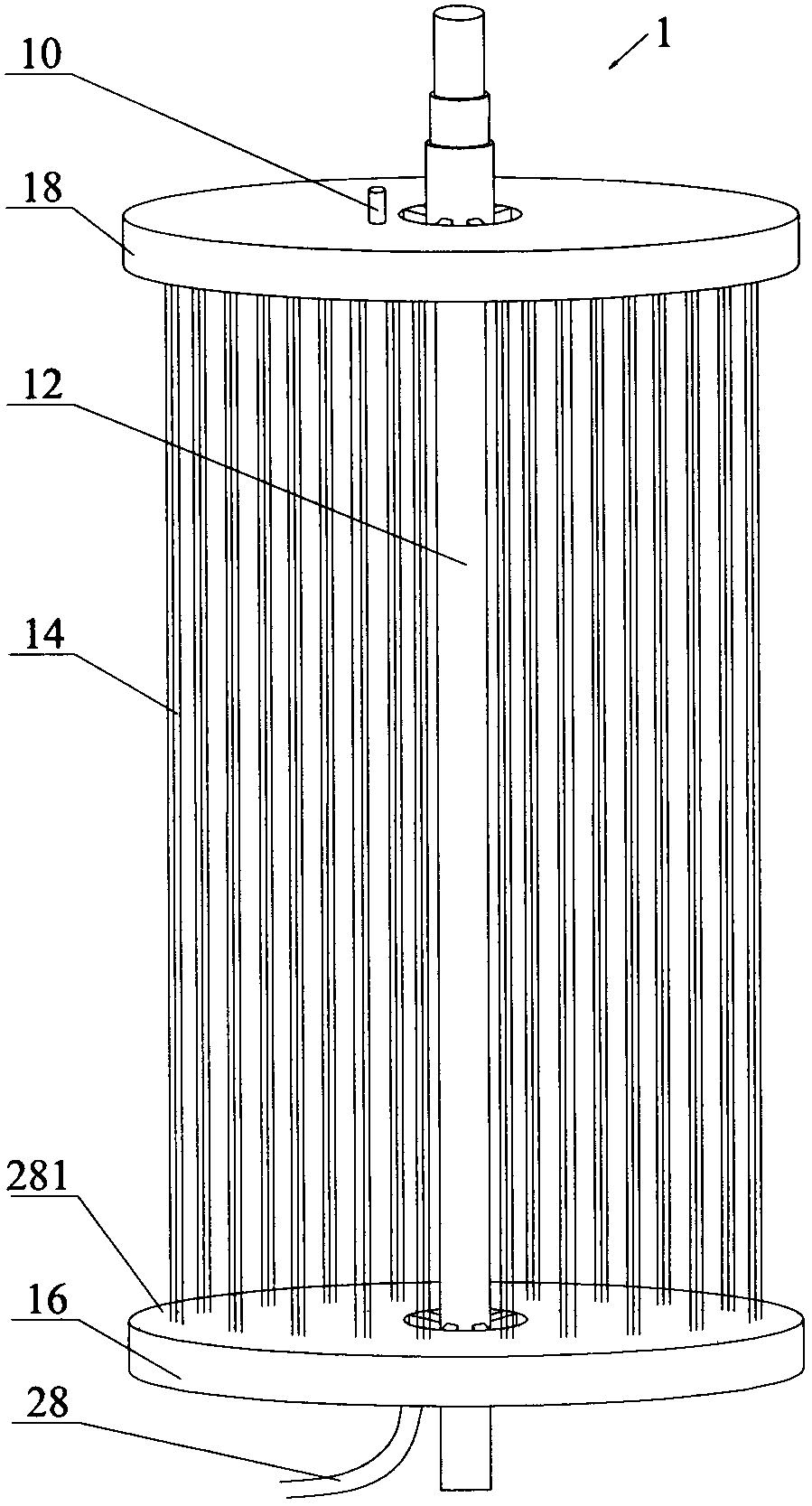

[0030] In the prior art, the membrane module is fixedly installed and the membrane unit is poorly decontaminated. figure 1 The present invention is shown to provide a membrane bioreactor including a rotating drum membrane module. The membrane bioreactor includes an ultrasonic unit 36, a rotating drum membrane module 1, an aeration unit, and a water collection unit; the aeration unit continuously performs aeration The water delivery hose 30 and the water collection pipe 300 in the water collection unit are conventionally arranged according to the prior art.

[0031] The aeration unit continues to aerate. When the rotating drum membrane assembly 1 needs to be cleaned, the first motor 10 drives the rotating drum membrane assembly 1 to rotate at a preset frequency through the rotating shaft 12, and the ultrasonic unit 36 is energized for ultrasonic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com