Pneumatic impact riveting machine

A technology of riveting machine and riveting head, applied in the field of riveting machine, to achieve the effects of convenient operation, overcoming adjustment difficulties and high synchronization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

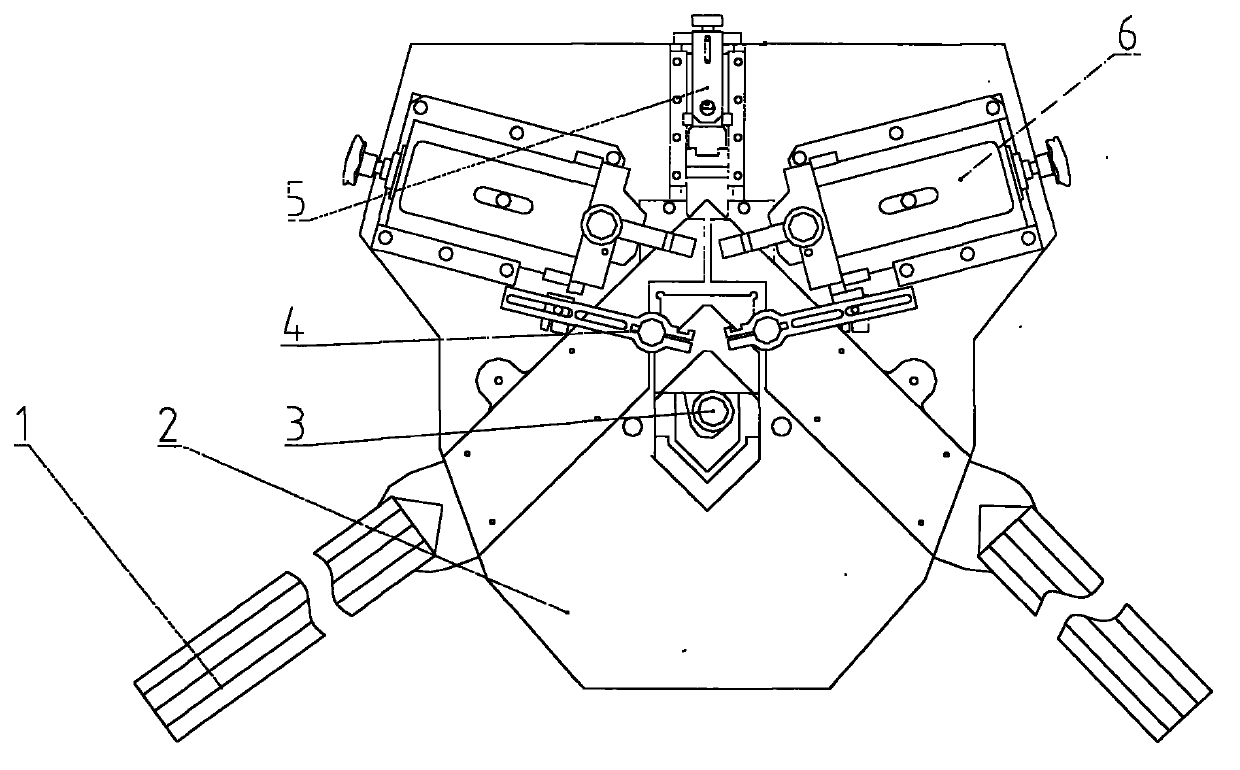

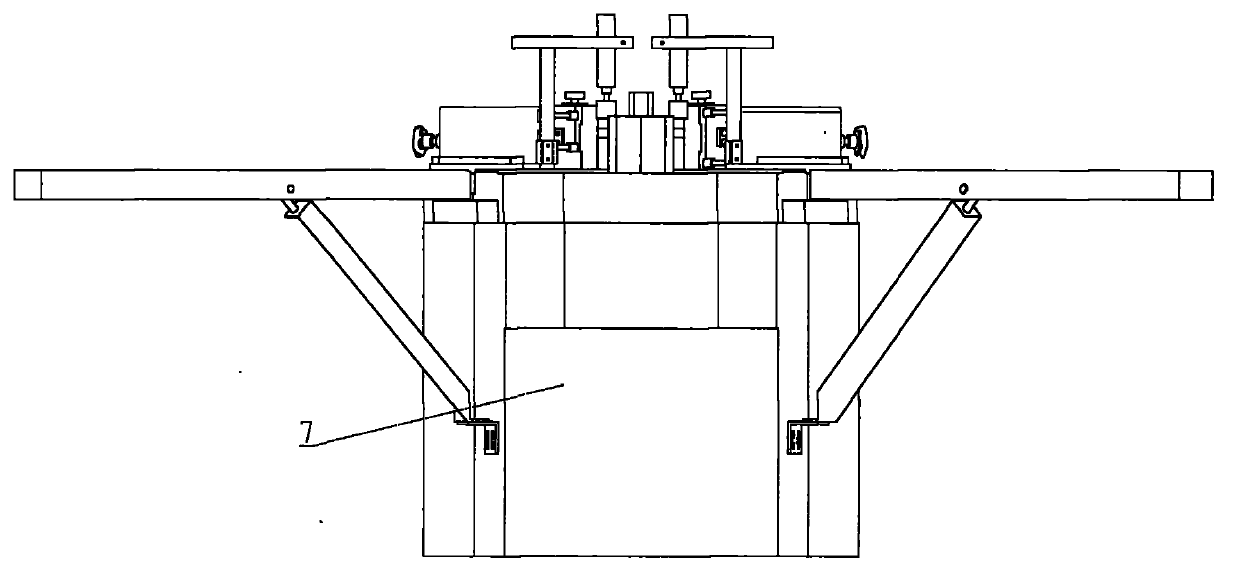

[0022] Such as figure 1 , figure 2 As shown, a pneumatic riveting machine includes a supporting device 1, a worktable 2, a main positioning device 3 that can be lifted and translated, a pressing device 4, an adjustable rear positioning device 5, an adjustable corner extrusion head 6 and a body 7 . The two adjustable rivet heads 6 complete work forward and work retreat along the guide device on the workbench 2 under the action of the same cylinder, so that the synchronization and stability of the two rivet heads are higher.

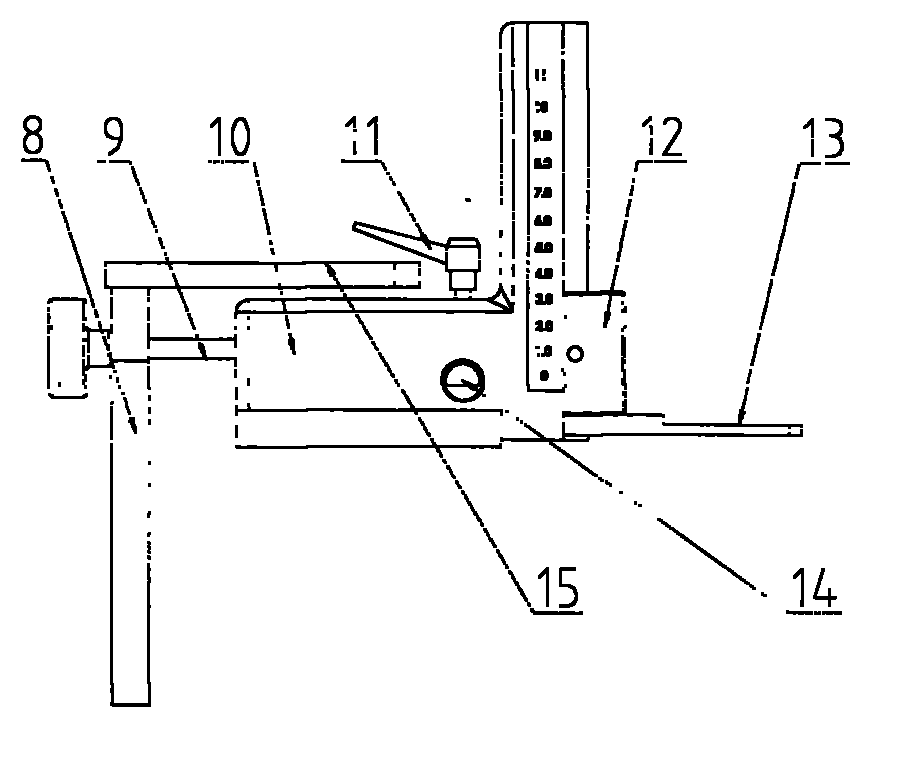

[0023] Such as image 3 As shown, the adjustable rear positioning device 5 includes: a rear positioning slide 10, a strong magnetic slider 12 adjusted up and down along the rear positioning slide 10, a rear positioning block 13 fixed on the slide 12, and adjustable by locking The fixed shaft 14 locked by the handle 11; the adjustment plate 8 fixed on the workbench 2, the adjustment plate 8 is provided with an adjustment screw 9, the threaded end of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com