Plastic particle extrusion welder

A plastic particle and welding machine technology, applied in the field of plastic welding processing, can solve the problems of operator fatigue, large weight and volume, uneven weld seam, etc., and achieve the effect of beautiful weld appearance, simple operation and high welding strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] Below, the substantive features and advantages of the present invention will be further described in conjunction with examples, but the present invention is not limited to the listed examples.

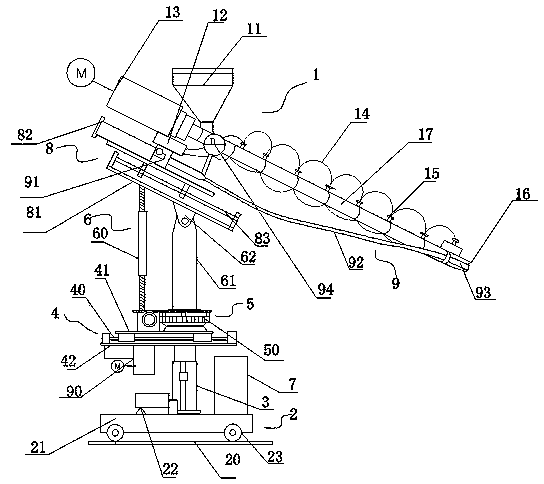

[0024] see figure 1 Shown, a kind of plastic granule extruding welding machine comprises:

[0025] The screw extrusion welding device 1 is used to preheat and melt the granular plastic and extrude the preheated and melted material according to the preset extrusion speed to weld the object to be welded;

[0026] The preheating device 9 is used to preheat the welding part of the object to be welded by blowing hot air before the screw extrusion welding device 1 welds the material, and;

[0027] The adjustment device is used to adjust the welding position and angle of the screw extrusion welding device, and the adjustment device includes:

[0028] The first X-direction adjustment device 2 installed horizontally on the ground, the first X-direction adjustment device 2 is verticall...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com