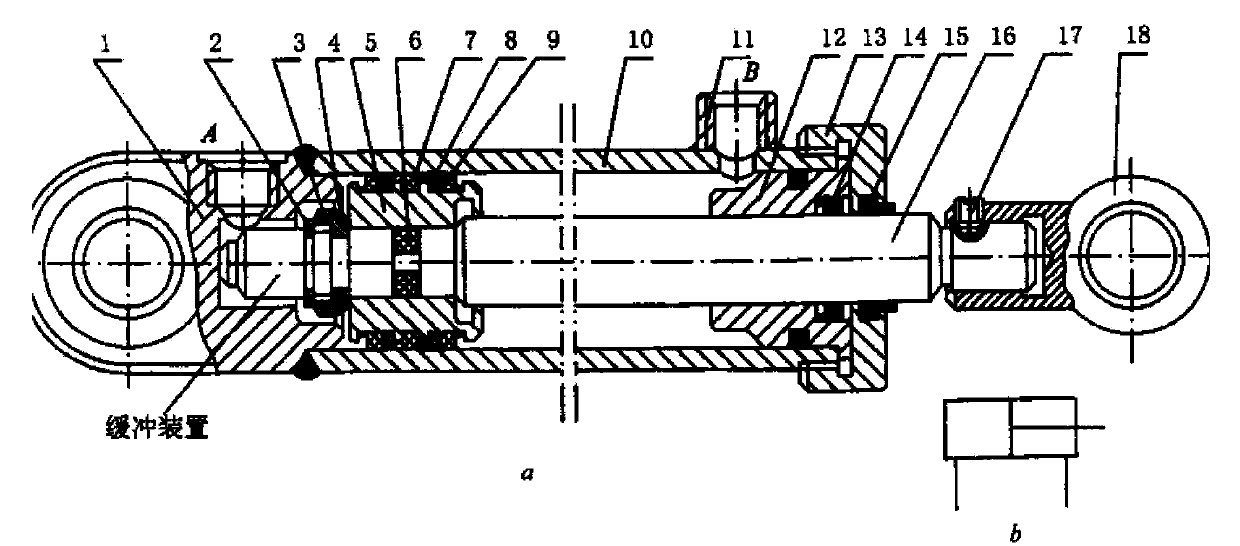

Hydraulic-drive automatic feeding system

An automatic feeding and hydraulic technology, which is applied in the direction of fluid pressure actuators, presses, servo motors, etc., can solve the problem that the processed parts should not be realized manually

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

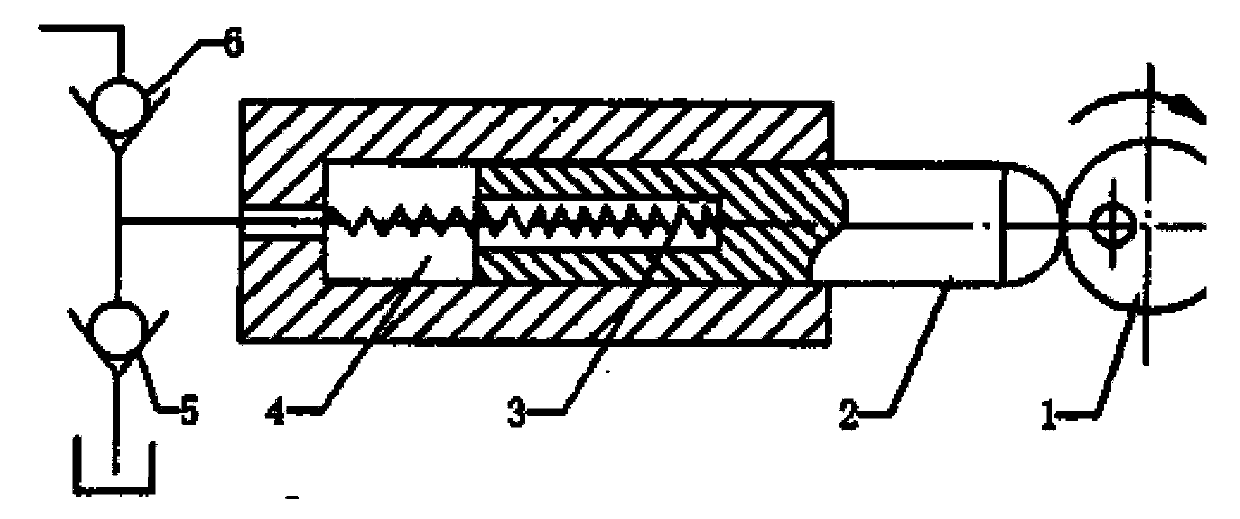

Embodiment Construction

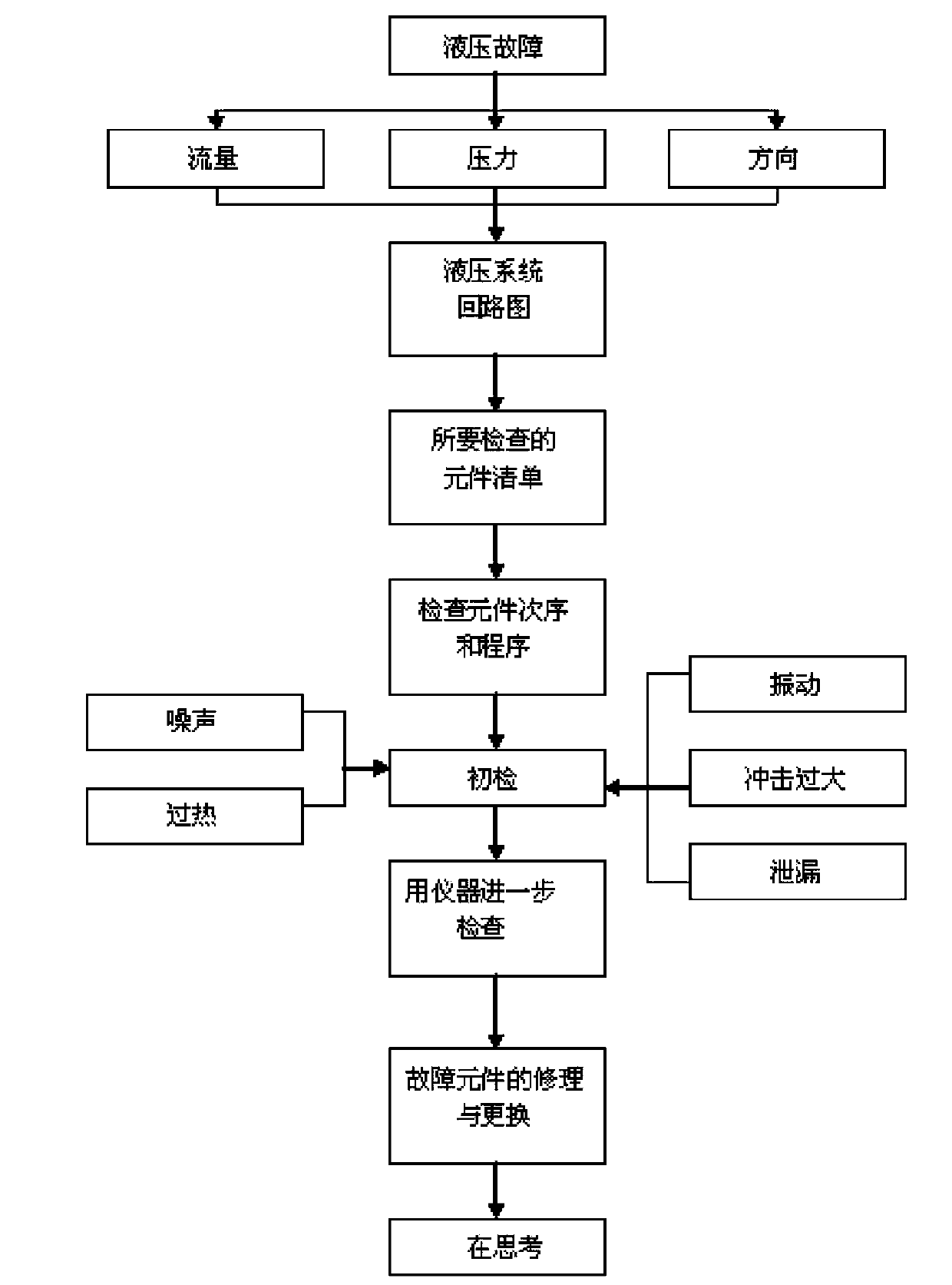

[0019] By connecting a one-way valve 6 in series to the circuit, the oil inlet circuit and oil return circuit are cut off during fast forwarding, so as to solve the problem that the oil inlet circuit and oil return circuit are connected to each other during fast forwarding of the slide table, and the pressure cannot be established. Hydraulic change. A hydraulic sequence valve 8 is connected in series on the oil return road to prevent the oil from returning to the oil tank during the fast-forward stage, which solves the problem that the oil return line is connected to the oil tank when the slide table is fast forwarding, and the differential connection of the hydraulic cylinder cannot be realized. Adding a check valve 1 at the outlet of the electro-hydraulic reversing valve solves the problem that the oil in the system flows to the oil tank when the system stops working, causing air to enter the system and affecting the stability of the sliding table movement. A pressure relay ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com