Continuous one-way moisture permeable coating film of automobile electric electronic equipment and manufacturing method of continuous one-way moisture permeable coating film

A technology of electronic equipment and manufacturing method, which is applied in the field of coating film, can solve the problems such as the large number of vent plugs and the inability to solve condensation, and achieve the effect of blocking the infiltration of dust

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0029] (2) Preparation of coating agent containing hydrophilic groups: Polyurethane, dimethylformamide solvent, hydrophilic group solvent and SiO 2 The mixture of fine powder is stirred and emulsified evenly to form a coating agent with hydrophilic groups;

[0030] (3) Manufacture of coating film: preparation before coating, coating agent containing hydrophilic groups is added to roller coating machine, coating thickness is adjusted, expanded polytetrafluoroethylene microporous film 1 is unwound, and glue is applied in contact with the roller , the next process is roller heating and drying of the coating film, winding, storage, aging and curing, and packaging.

[0031] Preferably, the manufacture of the expanded polytetrafluoroethylene microporous film 1: mix the polytetrafluoroethylene dispersion resin and the liquid extrusion aid in proportion, heat-preserve and mature at 30°C~35°C, and pre-press into a cylindrical blank , the cylindrical blank is made into a thin sheet by ...

Embodiment

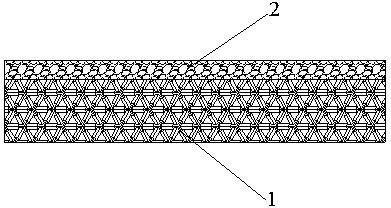

[0042] A continuous unidirectional moisture-permeable coating film for automotive electrical and electronic equipment, comprising: expanded polytetrafluoroethylene microporous film 1 and a coating 2 containing hydrophilic groups, the expanded polytetrafluoroethylene microporous film The surface of the porous film 1 is coated with a coating 2 containing hydrophilic groups, and its manufacturing method specifically includes the following steps:

[0043] (1) Manufacture of expanded polytetrafluoroethylene microporous film: mix polytetrafluoroethylene dispersion resin and aviation kerosene solvent at a mass ratio of 5:1, heat-preserve and mature at 30°C~35°C, and pre-press into a cylindrical blank , the cylindrical blank is made into a thin sheet by calendering, the extrusion aid is removed by heating at 90~110°C, uniaxially stretched at 190~210°C, biaxially stretched at 190~210°C, and sintered at 330~350°C for 15 ~20min heat setting, cooling, winding;

[0044] (2) Preparation of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| viscosity index | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com