Double-component windproof ventilating film

A windproof, breathable, two-component technology, applied in the direction of synthetic resin layered products, layered products, chemical instruments and methods, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

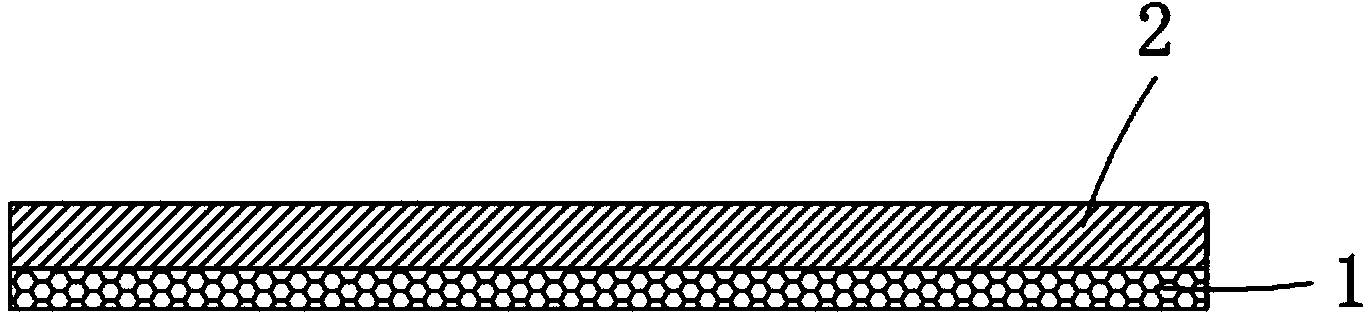

[0014] Examples, see attached figure 1 , a two-component windproof and breathable film, which includes a polytetrafluoroethylene base film 1 that has been processed by mixing, billeting, extrusion, calendering, stretching and sintering, and the top of the polytetrafluoroethylene base film is compounded One layer of microporous PU layer 2, the microporous PU layer and the polytetrafluoroethylene base film layer are combined by a release paper transfer method to form a two-component film.

[0015] The thickness of the PTFE base film is 4um, and the pore size of the PTFE base film is 1um. The PTFE base film has high temperature resistance, breathability and waterproof. In the film state, there are as many as 9 billion per square inch. The size of these small holes is one ten-thousandth of that of water droplets, but 700 times larger than that of water vapor molecules, which can effectively prevent liquid water from penetrating, and gaseous water molecules can pass through freely....

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com