Method and device for synthesizing copper azide

A technology of azide and copper nitride, applied in the direction of azide acid/azide/halogen azide, etc., can solve the problem of high risk of copper azide, achieve ingenious structure design, high safety, prevent Effect of escape of azide

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

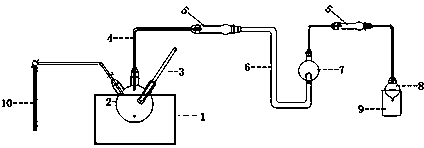

[0028] A method and device for synthesizing copper azide, the reaction device includes a heat-collecting magnetic stirrer 1, a three-necked flask 2, a thermometer (3), a right-angle elbow 4, a drying tube 5, and an "S" type Glass elbow 6, explosion-proof ball 7, anti-suckback ball 8, beaker 9 and nitrogen bottle 10. Silicone oil is used in the heat-collecting magnetic stirrer 1 oil bath; anhydrous calcium chloride desiccant is housed in the drying tube 5; KOH solution is filled in the beaker 9, and excess azide gas is recovered ; The reaction needs to be carried out under fume hood and effective protection. Copper azide synthesis process of the present invention is:

[0029] (1) Fix a 250mL round-bottomed three-necked flask in an oil bath with an iron stand, and add two-thirds of the volume of silicone oil to the oil bath; add a rotor and sodium azide (0.5g) to the three-necked flask and stearic acid (2.75g), add anhydrous calcium chloride to the drying tube and plug both en...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com