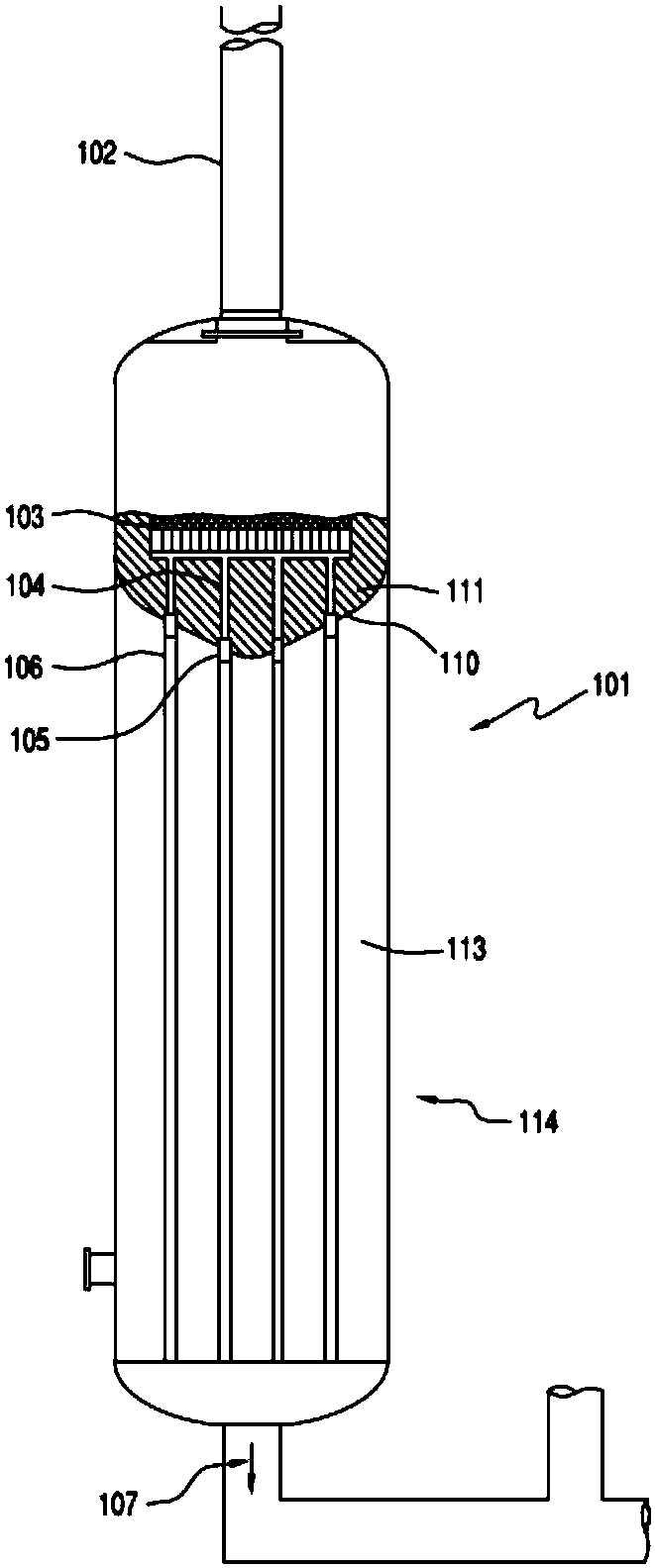

Method for stabilizing heat exchange tubes in the andrussow process

A technology of heat exchangers and sleeves, applied in heat exchange equipment, chemical instruments and methods, fixed tubular conduit assemblies, etc., can solve problems such as hindering commercial viability, excessively expensive sleeves, process efficiency and productivity reduction, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

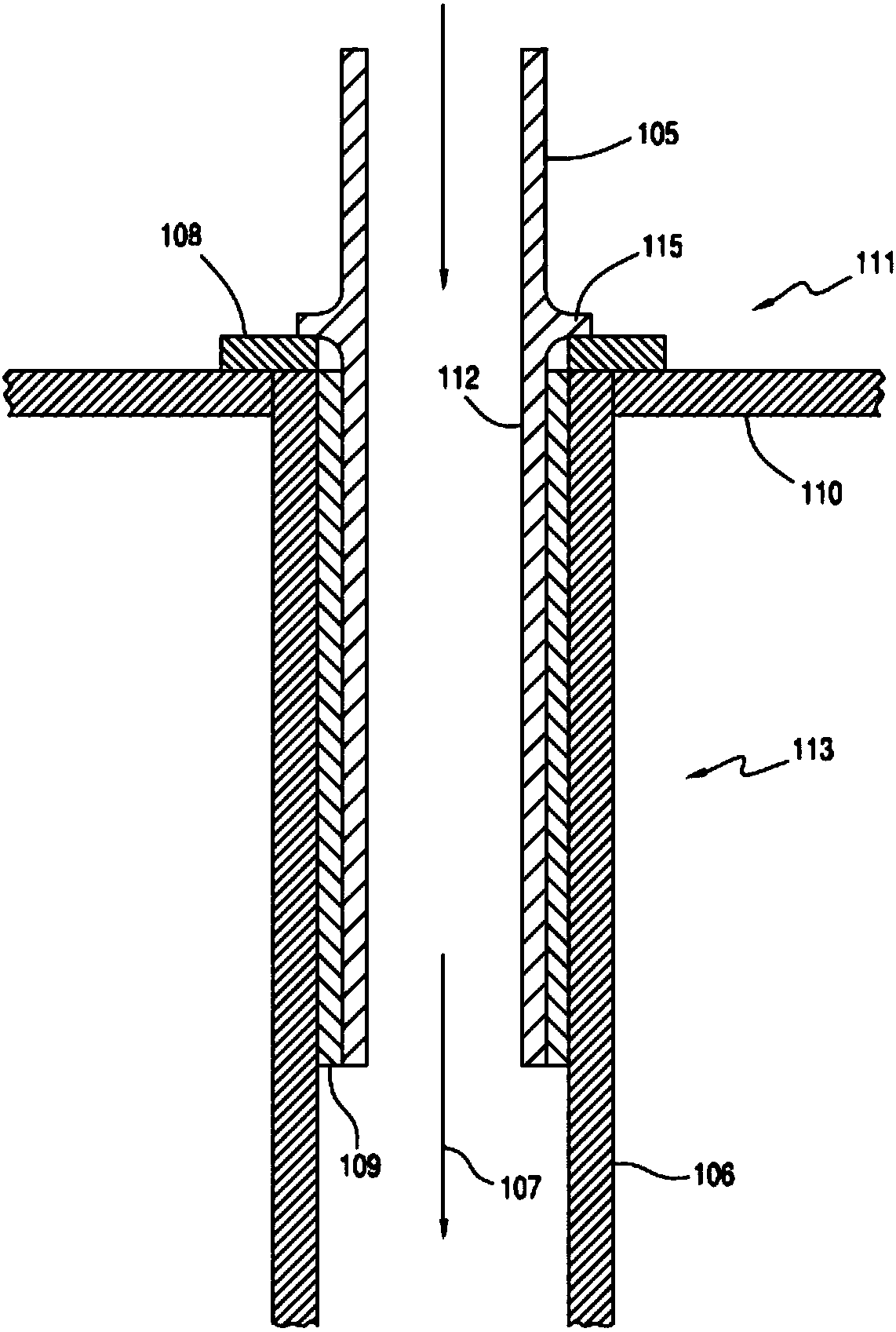

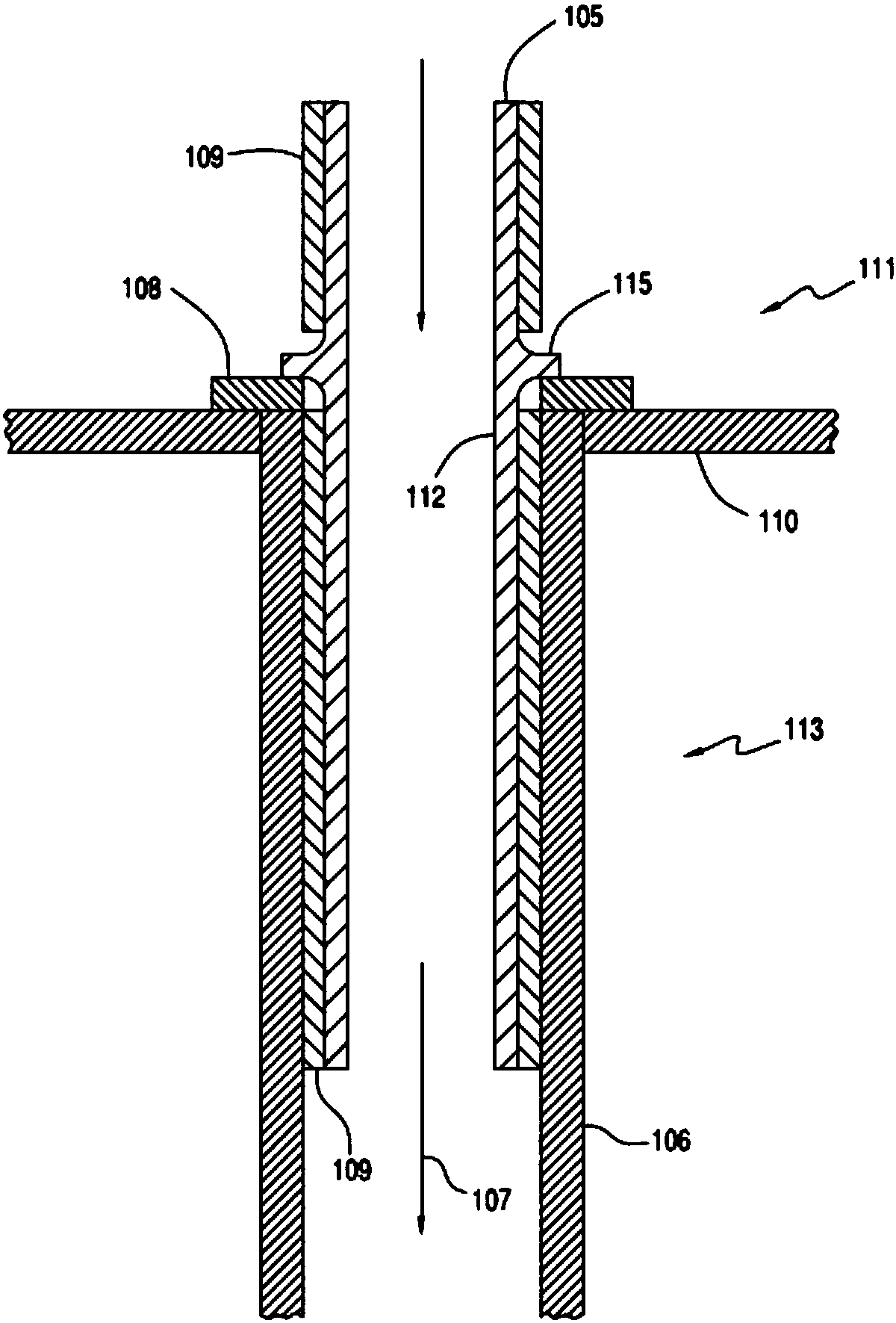

Embodiment 1

[0058] A ternary gas mixture is formed by combining oxygen-enriched air, ammonia-containing gas, and methane-containing gas. In this ternary gas mixture, the molar ratio of ammonia to oxygen is 1.3:1, and the molar ratio of methane to oxygen is 1.2. A ternary gas mixture containing 27-29.5 v% oxygen is reacted in the presence of a platinum / rhodium catalyst to form crude hydrogen cyanide. Hydrogen was generated during the reaction, and the crude hydrogen cyanide contained 34.5v% of hydrogen. The waste heat boiler consists of carbon steel tube sheets and 392 carbon steel waste heat boiler tubes. Each tube is surrounded by boiling water on all sides. Each tube included a sleeve containing 94 wt% alumina and 6 wt% silica. The length of each waste heat boiler tube is 914.4 cm, and the length of the casing is 17.8 cm. The sleeve extends through the inlet of the tube such that a portion of the sleeve extends 5.01 cm above the inlet of the waste heat boiler tube and 12.7 cm into t...

Embodiment 2

[0060] The crude hydrogen cyanide product was prepared and cooled as in Example 1 using the same casing and spacer as in Example 1, except that no spacers were used. The casing has a lifespan of 2 years.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com