Intermediate infrared optical glass for fine molding and molding

A technology of compression molding and infrared optics, which is applied in the field of optical glass for precision molding, can solve the problems of rare chalcogenide glass formulations, etc., and achieve the effects of strong anti-devitrification ability, good thermal stability, and simple preparation process

Inactive Publication Date: 2014-06-18

NANJING UNIV OF INFORMATION SCI & TECH

View PDF5 Cites 9 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

However, the disclosed chalcogenide glass formulations are either doped with rare earth elements to make laser materials, or the raw materials contain toxic elements such as As and Cd, or the glass formulations need to be quenched and formed. These formulations are not suitable for precision molding lenses. Materials, chalcogenide glass formulations that are really suitable for precision molding are rare

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

[0015] Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

[0016] Examples of preparation methods:

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| Vickers hardness | aaaaa | aaaaa |

| refractive index | aaaaa | aaaaa |

Login to View More

Abstract

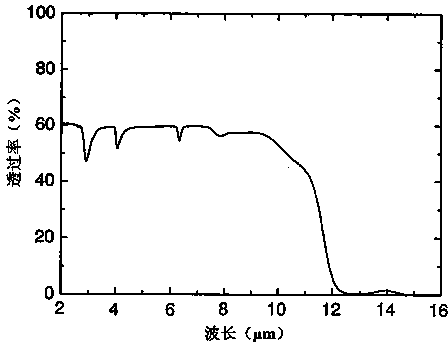

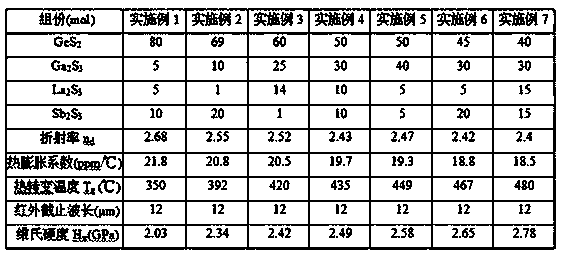

The invention discloses intermediate infrared optical glass for fine molding and molding. The intermediate infrared optical glass comprises the following components by molar ratio: 40-80% of GeS2, 5-40% of Ga2S3, 1-15% of La2S3 and 1-20% of Sb2S3. The intermediate infrared optical glass disclosed by the invention has a wide infrared transmission range, good glass-forming ability, simple preparation process, high refractive index, high mechanical strength and low glass transition temperature, and does not contain any ingredients adverse to the environment and the mold, such as lead, arsenic, fluorine, chromium and the like.

Description

technical field [0001] The invention relates to the technical field of infrared optical glass materials, in particular to an optical glass for precision molding that acts in the mid-infrared range. Background technique [0002] Infrared optical lenses are widely used in the fields of communication, laser, medical treatment, electric power, metallurgy, chemical industry, testing, fire protection and national defense. Aspherical mirrors have been widely used because of the advantages of good imaging quality, small size, light weight, and simple structure in optical systems. [0003] Glass lens precision molding technology is a high-precision optical element processing technology. It puts the glass preform into a high-precision mold, and under the conditions of heating, pressure and oxygen-free, it is directly molded at one time to meet the requirements of use. Optical parts required. Precision molding technology can directly mold precision aspheric or spherical optical parts...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): C03C3/32

Inventor 汪国年季平

Owner NANJING UNIV OF INFORMATION SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com