A kind of preparation method of yttrium-doped yellow-green glass

A yellow-green light and glass technology, applied in the field of preparation of yttrium-doped yellow-green light glass, can solve the problems of irregular particle morphology, thermal stability difference, wide particle size distribution, etc. Excellent glass performance and stable color

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] 1) First, 18mol% of Tb will be 2 o 3 , 24mol% B 2 o 3 , 15mol% Ga 2 o 3 , 5.2mol% Y 2 o 3 , 15mol% GeO 2 , 22mol% SiO 2 , 0.3mol% SnO 2 , 0.5mol% ZrO 2 Mix until the uniformity is greater than 98% to form a batch;

[0023] 2) Then, add the batch material into the platinum crucible that has been heated to 1450°C; keep warm for 30 minutes;

[0024] 3) Then, cool down the furnace temperature to 1380°C for 30 minutes and keep it warm for 30 minutes;

[0025] 4) Finally, pour the molten glass into a graphite mold at 250°C, put it into a furnace at 710°C after setting the shape, keep it warm for 3 hours, and then cool it down to room temperature at a cooling rate of 1°C / min to obtain a transparent yellow-green light. Glass.

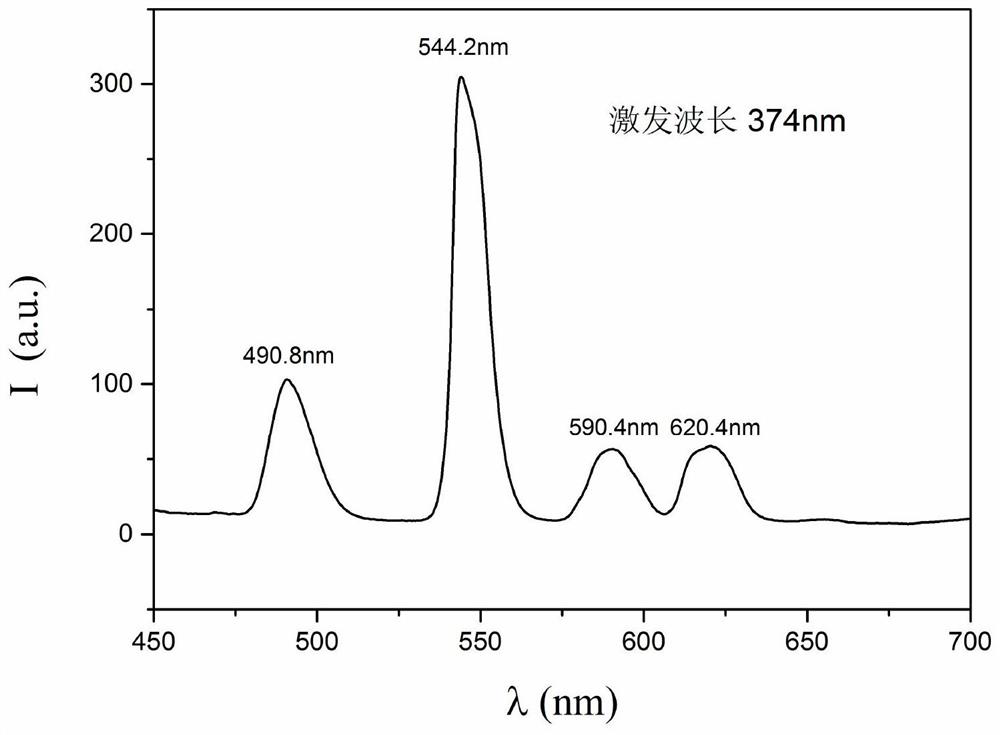

[0026] attached figure 1 It is the photoluminescence spectrum of the prepared colorless transparent yellow-green light-emitting glass at an excitation wavelength of 374nm, wherein the abscissa is the wavelength of emitted light, and the ord...

Embodiment 2

[0029]1) First, 21.85mol% of Tb will be 2 o 3 , 24mol% B 2 o 3 , 13mol% Ga 2 o 3 , 2mol% Y 2 o 3 , 17mol% GeO 2 , 20mol% SiO 2 , 0.5mol% Sb 2 o 3 , 1mol% SnO 2 , 0.65mol% ZrO 2 Mix until the uniformity is greater than 98% to form a batch;

[0030] 2) Then, add the batch material into the platinum crucible that has been heated to 1460°C; keep warm for 30 minutes;

[0031] 3) Then, cool down the furnace temperature to 1380°C for 30 minutes and keep it warm for 30 minutes;

[0032] 4) Finally, pour the molten glass into a graphite mold at 315°C, put it into a furnace at 710°C after setting the shape, keep it warm for 3 hours, and then cool it down to room temperature at a cooling rate of 1°C / min to obtain a transparent yellow-green light. Glass.

Embodiment 3

[0034] 1) First, 20mol% of Tb will be 2 o 3 , 22mol% B 2 o 3 , 11mol% Ga 2 o 3 , 6mol% Y 2 o 3 , 14.9 mol% GeO 2 , 24mol% SiO 2 , 0.6mol% Sb 2 o 3 , 0.5mol% SnO 2 , 1mol% ZrO 2 Mix until the uniformity is greater than 98% to form a batch;

[0035] 2) Then, add the batch material into the platinum crucible which has been heated to 1475°C; keep warm for 30 minutes;

[0036] 3) Then, cool down the furnace temperature to 1380°C for 30 minutes and keep it warm for 30 minutes;

[0037] 4) Finally, pour the molten glass into a graphite mold at 350°C, put it into a furnace at 710°C after setting the shape, keep it warm for 3 hours, and then cool it down to room temperature at a cooling rate of 1°C / min to obtain a transparent yellow-green light. Glass.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com