Preparation method of high erbium-doped Faraday optical rotation glass

A technology of Faraday rotation and high dosage, which is applied in the field of preparation of Faraday rotation glass, and achieves the effects of excellent thermal stability and chemical stability, low melting temperature and excellent formability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] Embodiment 1: 1) at first, according to mass fraction with 65% Er 2 o 3 , 20% Ga 2 o 3 , 5% B 2 o 3 , 5% SiO 2 , 1.9% CeO 2 , 0.1% Sb 2 o 3 , 0.5% ZnO, 0.5% ZrO 2 and 2% Al 2 o 3 After mixing evenly, a batch material is formed;

[0019] 2) Then, add half of the batch material into the corundum crucible that has been heated to 1250°C; then, raise the temperature to 1450°C for 10 minutes, and keep it warm for 20 minutes; then add the remaining batch material to the corundum crucible, and pass it for 10 minutes Raise the temperature to 1500°C, keep it warm for 60 minutes, stir the molten glass with a stirring rod for 1 minute, and raise the temperature to 1500°C again after 10 minutes, after holding it for 60 minutes, stir the molten glass with a stirring rod for 1 minute again, and pass it again for 10 minutes Raise the temperature to 1450°C and keep it warm for 30 minutes, then pour the molten glass into a graphite mold preheated to 500°C for molding;

[002...

Embodiment 2

[0024] Embodiment 2: 1) at first, according to mass fraction with 60% Er 2 o 3 , 22% Ga2 o 3 , 8% B 2 o 3 , 5% SiO 2 , 1.9% CeO 2 , 0.1% Sb 2 o 3 , 0.5% ZnO, 0.5% ZrO 2 and 2% Al 2 o 3 After mixing evenly, a batch material is formed;

[0025] 2) Then, add half of the batch material into the corundum crucible that has been heated to 1250°C; then, raise the temperature to 1450°C for 10 minutes, and keep it warm for 20 minutes; then add the remaining batch material to the corundum crucible, and pass it for 10 minutes Raise the temperature to 1450°C, keep it warm for 60 minutes, stir the molten glass with a stirring rod for 1 minute, and raise the temperature to 1450°C again after 10 minutes. Raise the temperature to 1400°C and keep it warm for 30 minutes, then pour the molten glass into a graphite mold preheated to 500°C for molding;

[0026] 3) Finally, put the molded sample into a muffle furnace at 650°C for 3 hours; finally, cool the sample to room temperature at a...

Embodiment 3

[0028] Embodiment 3: 1) at first, according to mass fraction with 62% Er 2 o 3 , 16% Ga 2 o 3 , 11% B 2 o 3 , 5% SiO 2 , 2% CeO 2 , 0.1% Sb 2 o 3 , 0.9% ZnO, 1% ZrO 2 and 2% Al 2 o 3 After mixing evenly, a batch material is formed;

[0029] 2) Then, add half of the batch material into the corundum crucible that has been heated to 1250°C; then, raise the temperature to 1450°C for 10 minutes, and keep it warm for 20 minutes; then add the remaining batch material to the corundum crucible, and pass it for 10 minutes Raise the temperature to 1480°C, keep it warm for 60 minutes, stir the molten glass with a stirring rod for 1 minute, and raise the temperature to 1480°C again after 10 minutes. Raise the temperature to 1400°C and keep it warm for 30 minutes, then pour the molten glass into a graphite mold preheated to 500°C for molding;

[0030] 3) Finally, put the molded sample into a muffle furnace at 660°C for 3 hours; finally, cool the sample to room temperature at a ...

PUM

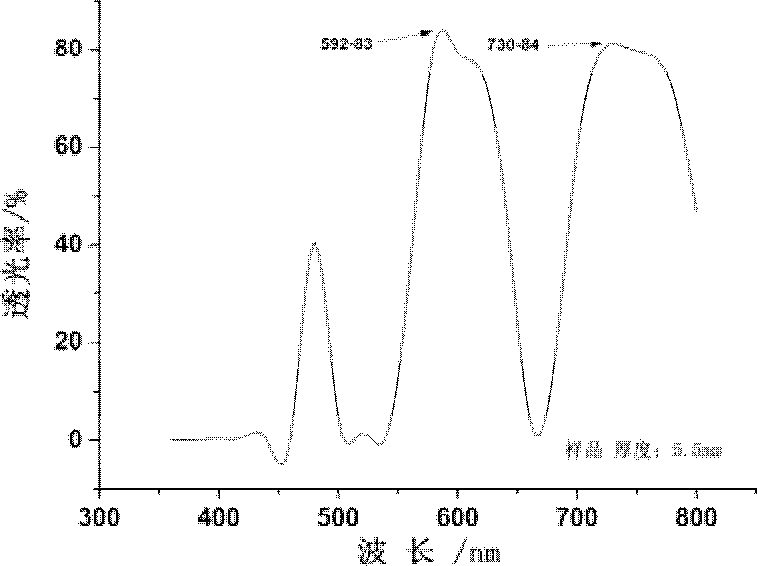

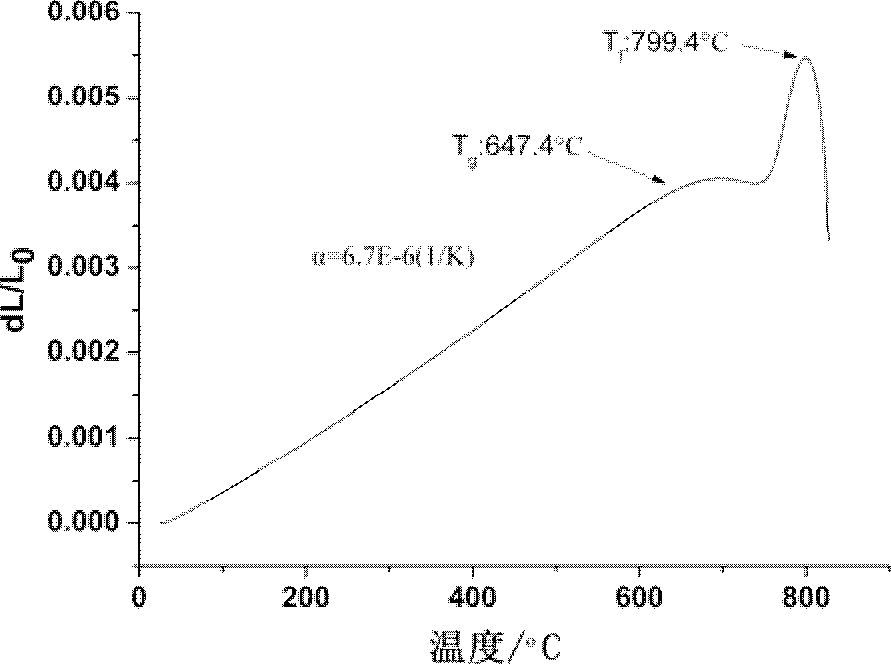

| Property | Measurement | Unit |

|---|---|---|

| transition temperature | aaaaa | aaaaa |

| transmittivity | aaaaa | aaaaa |

| transmittivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com