Optimized and fused simulation space optics-electromagnetic shielding environment composite darkroom

A technology of electromagnetic shielding and simulating space, applied in small buildings and other directions, it can solve the problems of poor aesthetics in darkrooms, prone to fire accidents, and failure of wave absorbers, and achieves the protection of information security and stability, high electromagnetic shielding efficiency, and small measurement errors. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

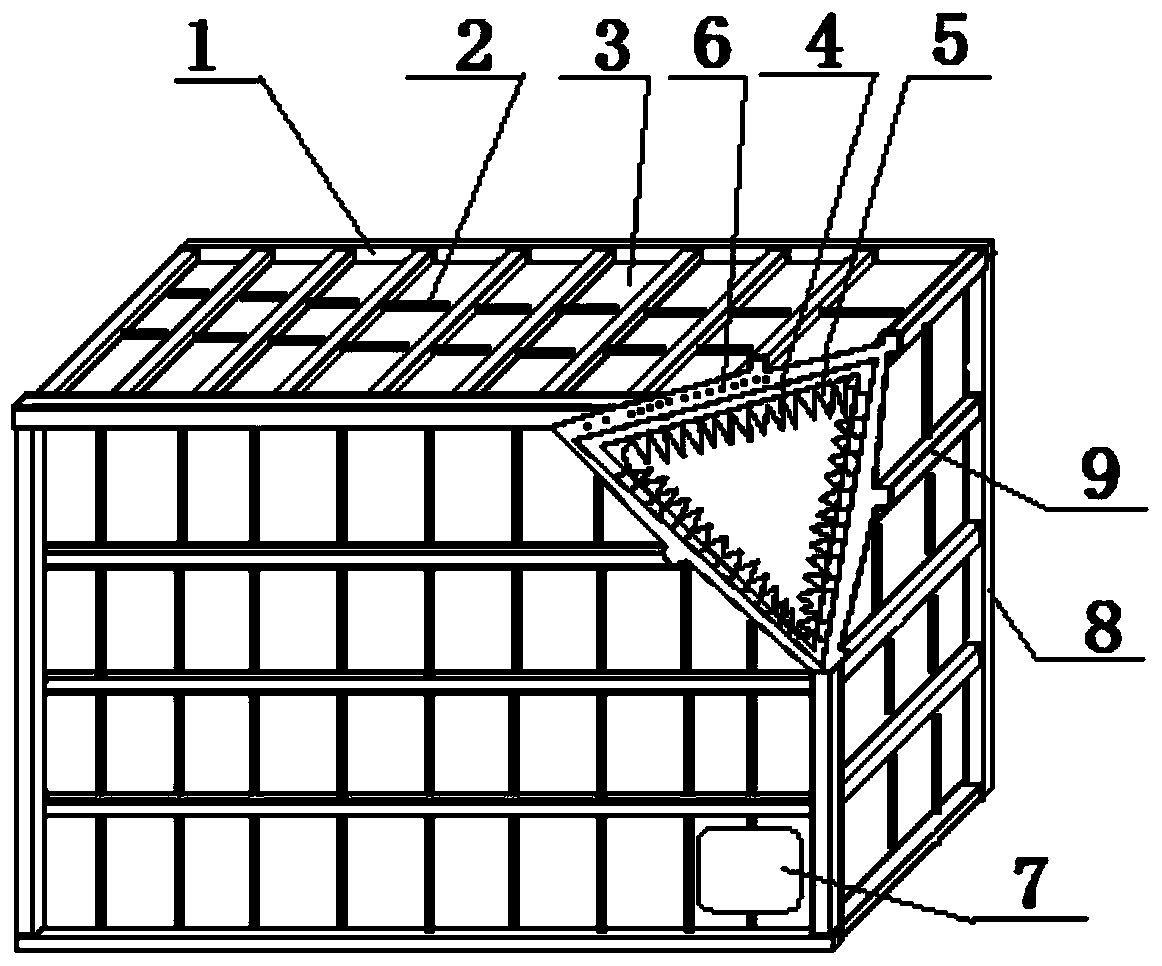

[0058] Embodiment 1: as attached figure 1 As shown, the darkroom is a six-sided square frame structure, and the inside of the four side walls and the bottom of the ceiling are installed with keel-back frames all over the place to mount the light-absorbing wedge 5, that is, the inner side of the six-sided square frame is installed by the main keel 9 and the auxiliary keel 2 The grid back frame 6 formed, and then the absorbing base 4 is mounted on the grid back frame 6 opaquely and densely, and the light-absorbing wedge 5 is installed on the wave-absorbing base 4; The visible surface has a matte coating 12 .

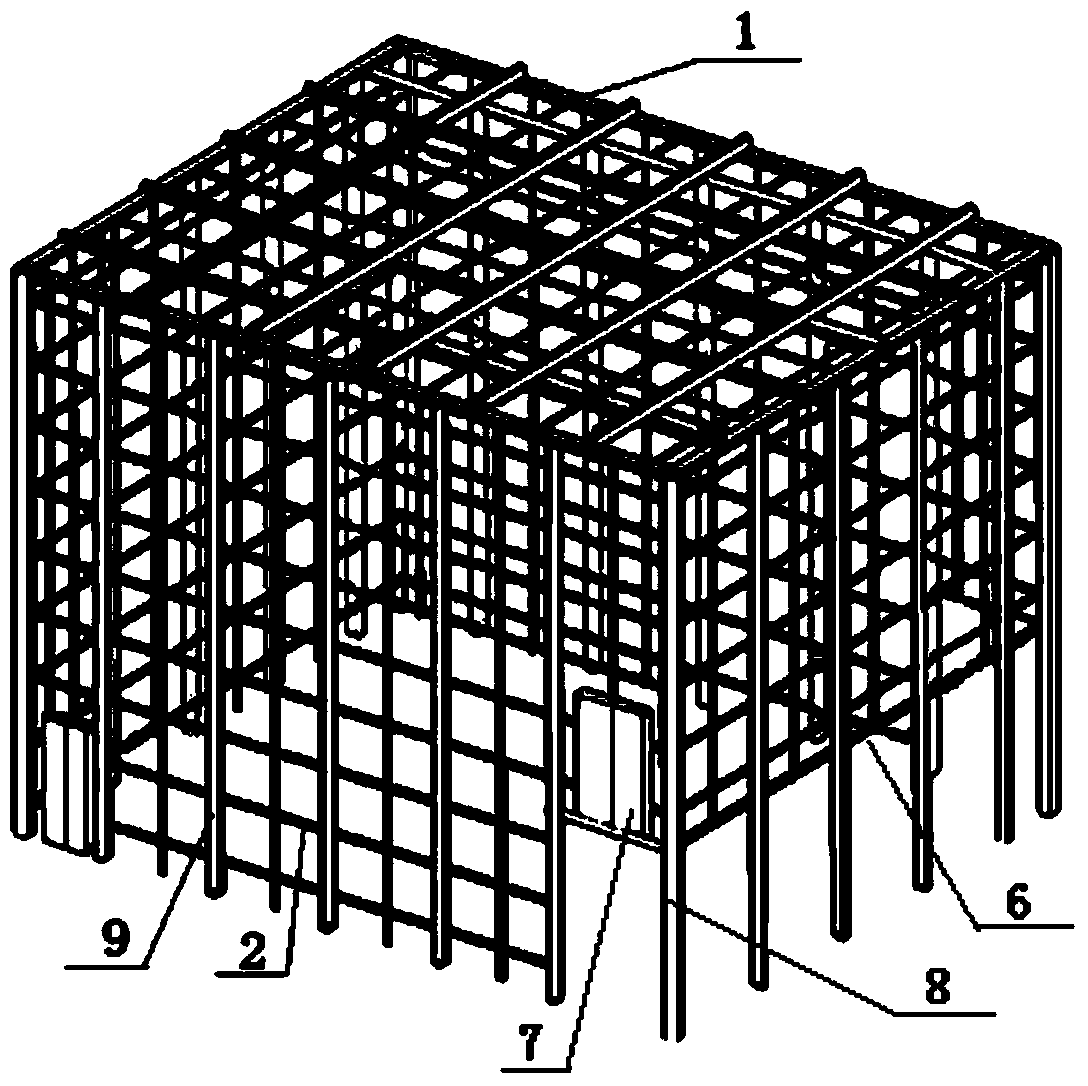

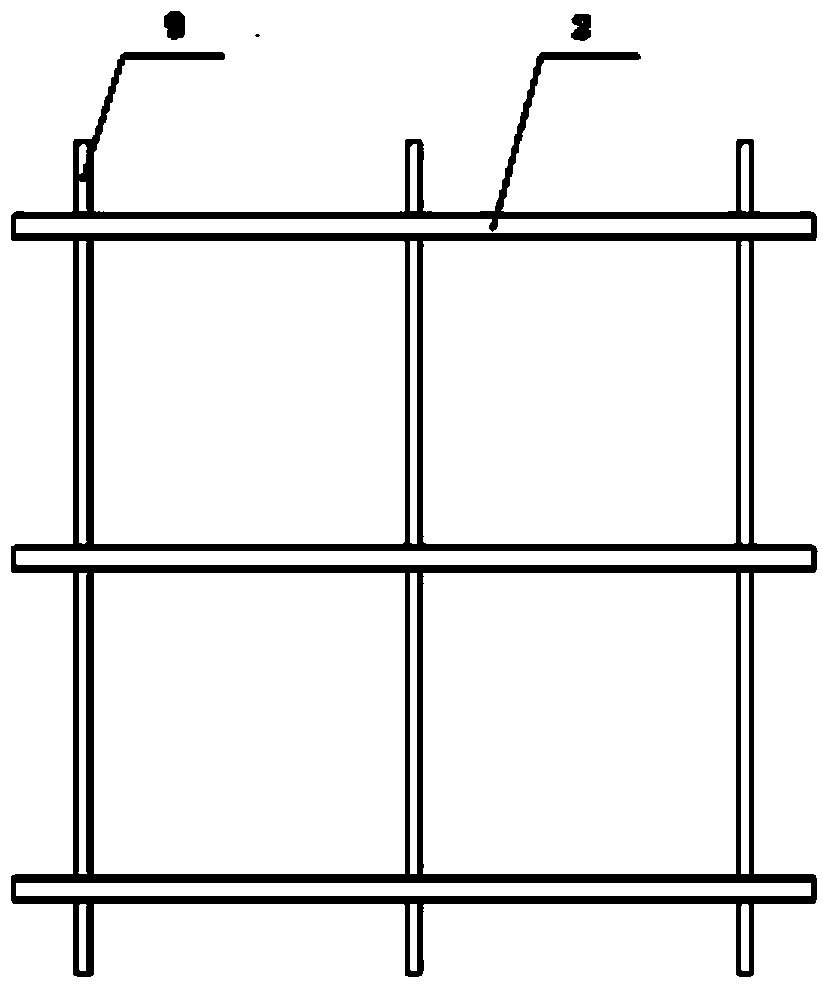

[0059] In the foregoing, as attached figure 2 As shown, the six-sided square frame structure of the darkroom is composed of a group of main beams 1 in the horizontal direction on the top and a group of main columns 8 in the vertical direction. A grid back frame 6 formed by cross connections. A grounding device 7 is installed and connected to the outside of the mesh ba...

Embodiment 2

[0080] The main keel 9 stands on the ground, the auxiliary keel 2 is welded on the main keel 9, and the shielding steel plate 3 is welded on the back frame composed of the main keel 9 and the auxiliary keel 2; cold-rolled steel plate; all extinction absorbing wedges 5 are only coated with a layer of extinction coating 12 before hanging; the actual measurement shows that the extinction effect of the darkroom reaches 95.5%, and the electrical performance of the darkroom has a shielding effect of 90dB on 2GHZ-18GHZ microwave signals.

Embodiment 3

[0082] It is basically the same as Example 2, except that the matting and absorbing wedge 5 is coated with three layers of matting coatings 12 before hanging; simultaneously, the matting efficiency of the darkroom is improved.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Shielding effectiveness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com