Rankine cycle engine with rotary shell

A Rankine cycle engine technology, applied in the field of rotary casing Rankine cycle engines, can solve problems such as bulky, bulky, and complex pumping systems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

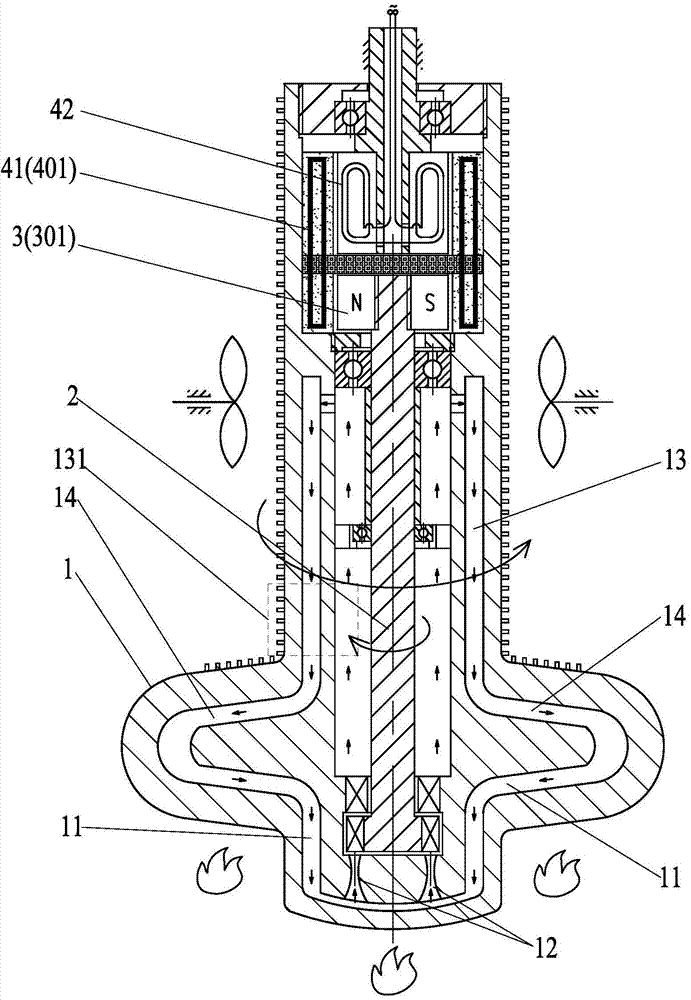

[0080] Such as figure 1 The rotary casing Rankine cycle engine shown includes a rotating airtight outer casing 1, an independent impeller rotor 2, a permanent magnet 3, an injection injection channel and a rotating induction coil, and a working medium heating channel 11 is arranged on the rotating airtight outer casing 1, The injection injection channel is arranged with the rotating airtight outer shell 1 at an angle, the gas-phase working medium outlet of the working medium heating channel 11 communicates with the working medium inlet of the injection injection channel, and the impeller independent rotor 2 is arranged on the The inside of the rotating airtight outer casing 1, the rotation axis of the impeller independent rotor 2 is collinear with the rotation axis of the rotating airtight outer casing 1, and the impeller independent rotor 2 is arranged in rotation with the rotating airtight outer casing 1, The gas working medium injected by the injection injection channel ac...

Embodiment 2

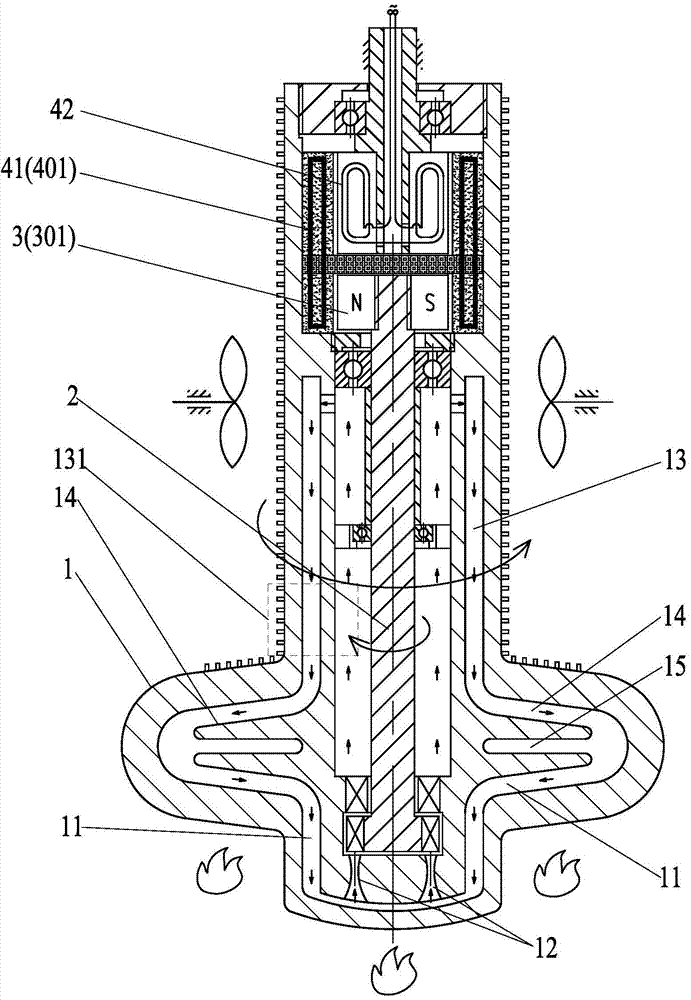

[0083] Such as figure 2 The rotary casing Rankine cycle engine shown is based on Embodiment 1: a working fluid storage space 15 is provided on the rotating airtight outer casing 1, and the working fluid storage space 15 communicates with the working fluid circulation channel.

Embodiment 3

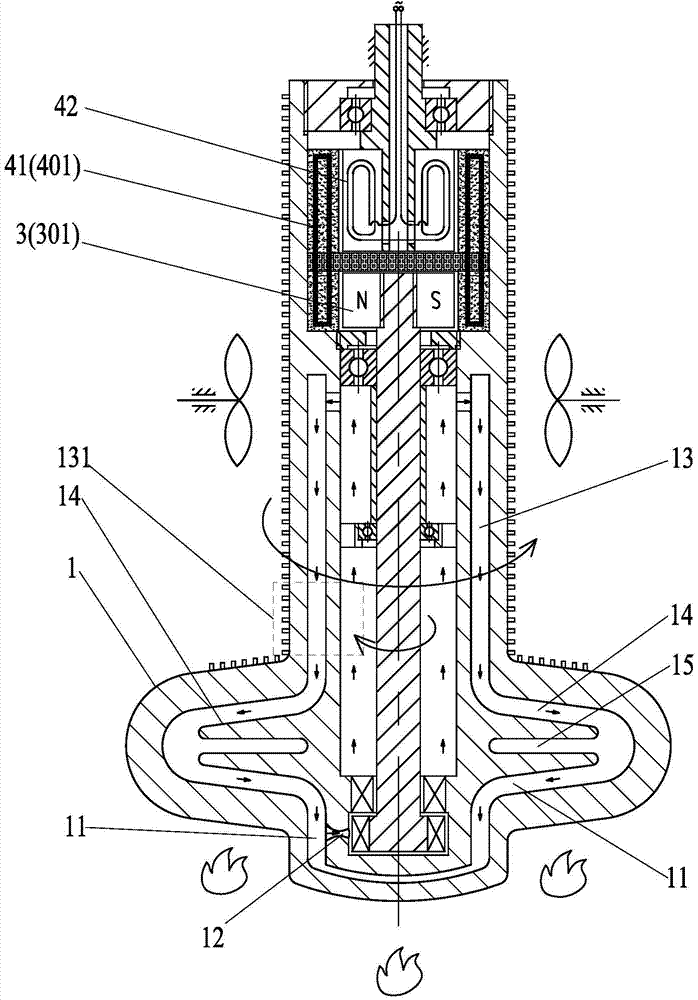

[0085] Such as image 3 Shown rotary casing Rankine cycle engine, its difference with embodiment 2 is:

[0086] The inner injection Laval nozzle 12 is changed to be arranged radially with the rotating airtight outer casing 1, and the impeller structure is set as a radial flow turbine.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com