Diesel engine inlet air humidifying system with high humidifying efficiency

A humidification system, diesel engine technology, applied in charging systems, mechanical equipment, engine components, etc., can solve the problems of small contact surface between intake air and atomized droplets, limited number of nozzles, complex structure, etc. Flexible and controllable, improve humidification efficiency, and increase the effect of contact area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

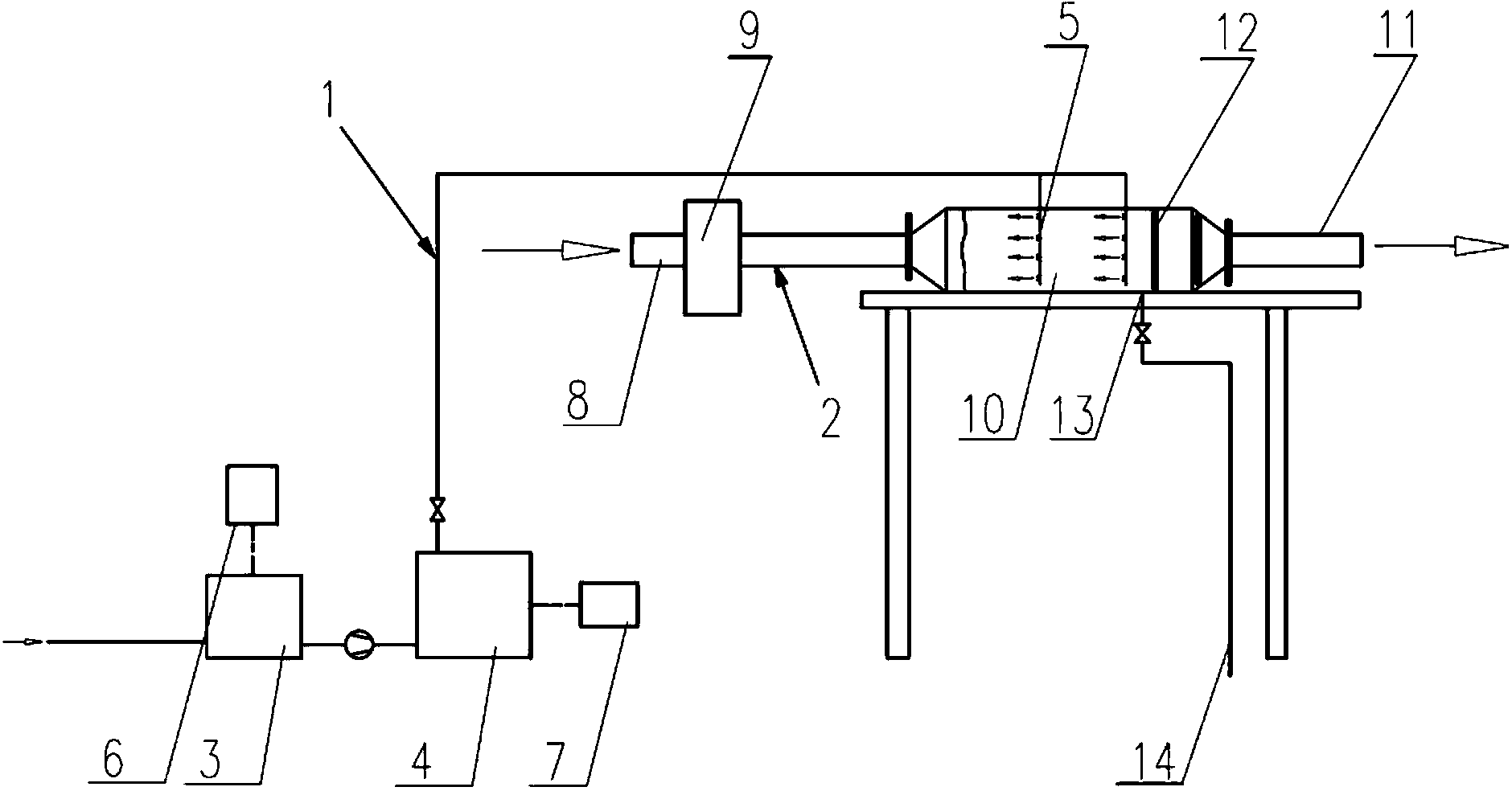

[0029] Such as figure 1 As shown, an air intake humidification system for a marine diesel engine includes a water spray pipeline 1, an air intake pipeline 2, a main control box 7 and an auxiliary control box 6, and the water spray pipeline 1 is sequentially provided with an automatic constant temperature water tank 3 along the waterway direction , high-pressure micro-mist device 4 and water spray device 5. The main control box 7 is connected with the high-pressure micro-mist device 4, and the main control box 7 controls the opening and closing of each spray branch pipe in the nozzle group 5 through the high-pressure micro-mist host 4 (or solenoid valve). The auxiliary control box 6 is connected with the automatic constant temperature water tank 3, and is used to control the temperature and liquid level of the water stored in the water tank.

[0030] Optionally, the water injection port of the water spray device 5 faces into the intake pipe of the diesel engine; the intake pip...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com