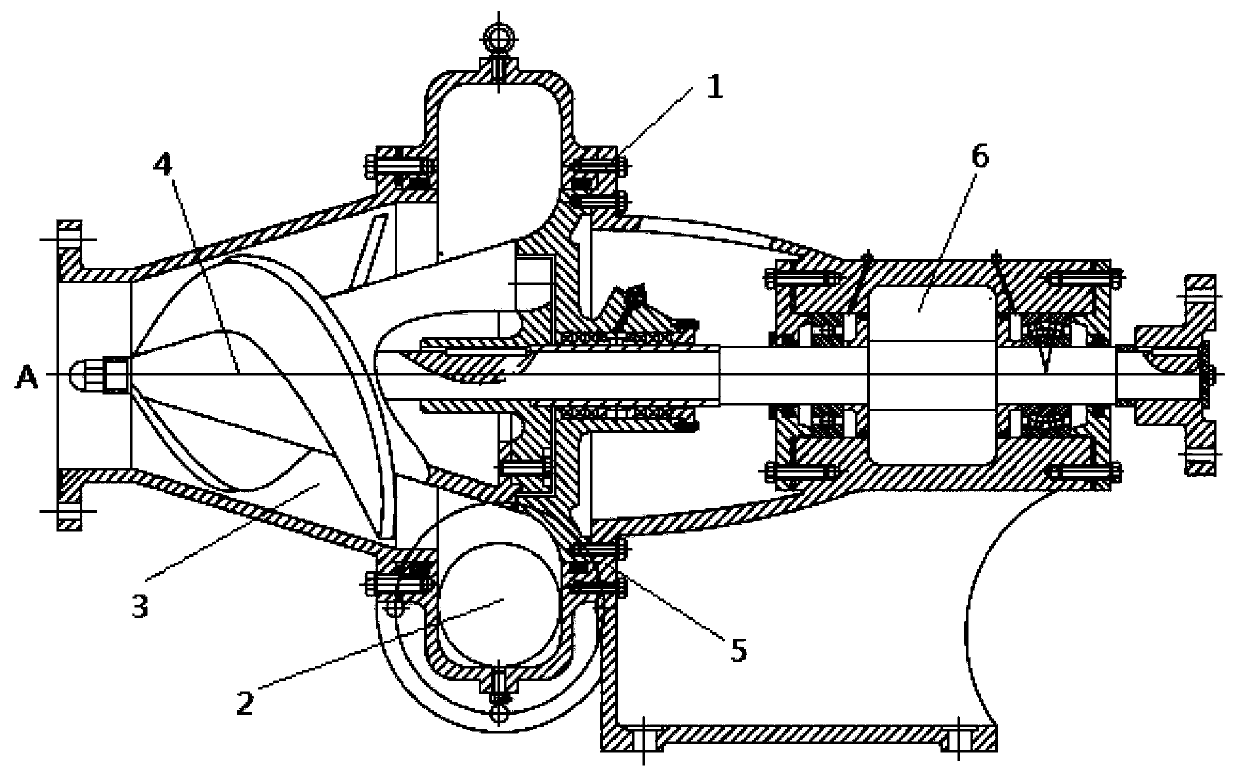

Spiral centrifugal pump

A technology of spiral and spiral impeller, which is applied in the field of spiral sand and gravel pump equipment, can solve the problems of material damage, insufficiency, winding and blockage, etc., and achieve the effect of improving the technological level.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] Connect point A to the water inlet pipe, open the bottom valve ⑸ to fill the pressurized water chamber ⑶ with water, adjust the regulating valve ⑴ to the desired value, turn on the motor ⑹, and the motor shaft drives the spiral impeller ⑷ to perform high-speed rotation, forcing the pressurized water chamber The liquid in the water chamber ⑶ rotates, and the liquid is discharged from the discharge short pipe ⑵ by centrifugal action, and the water is sucked into the pressurized water chamber ⑶ from A, and the cycle is like this.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com