Aluminum based alloy sliding bearing bush

An aluminum-based alloy and sliding shaft technology, applied in the direction of bearing components, shafts and bearings, mechanical equipment, etc., can solve the problems affecting the operation of the unit, slag accumulation, etc., to solve the effect of not being durable and improving the use efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

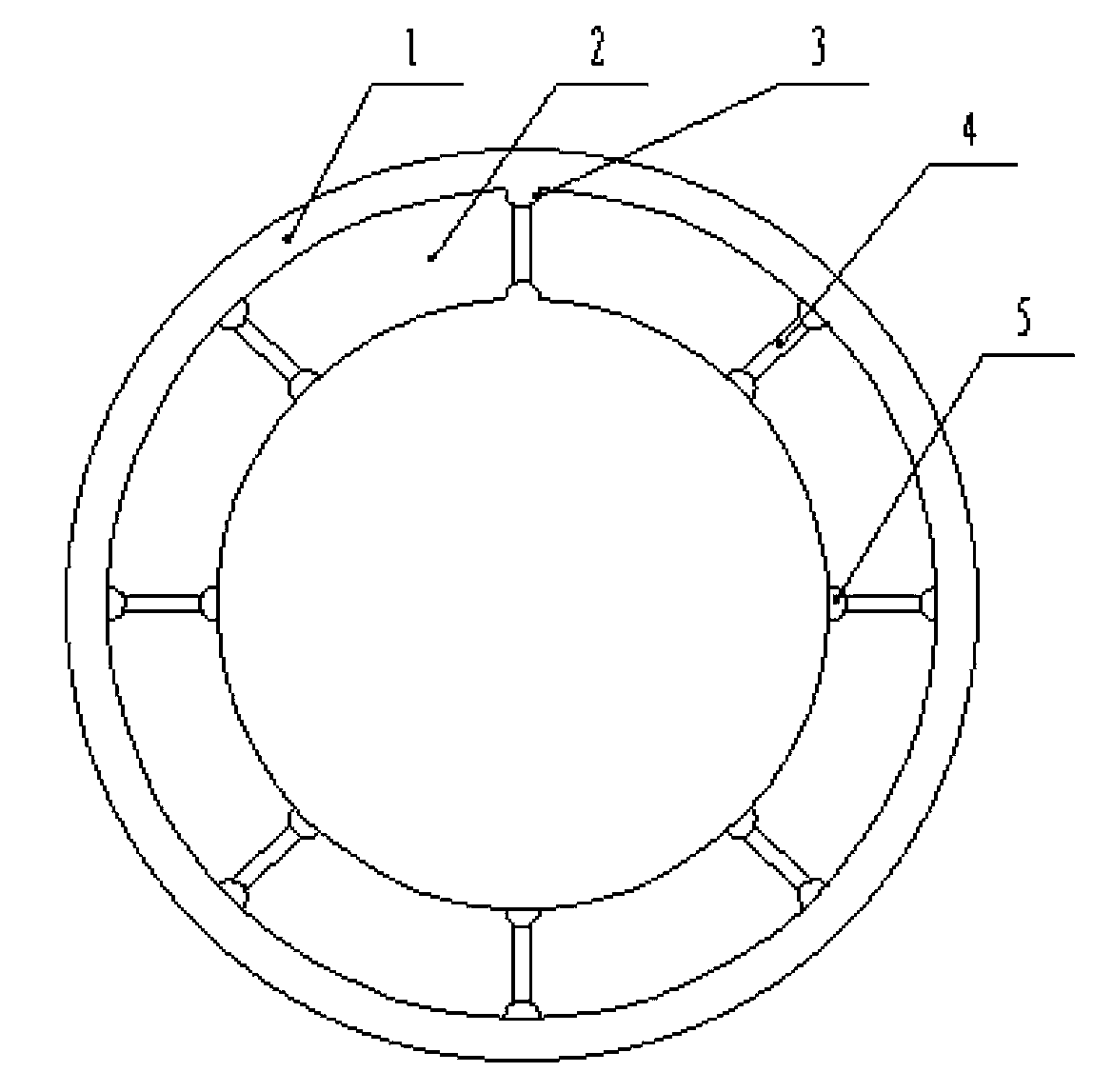

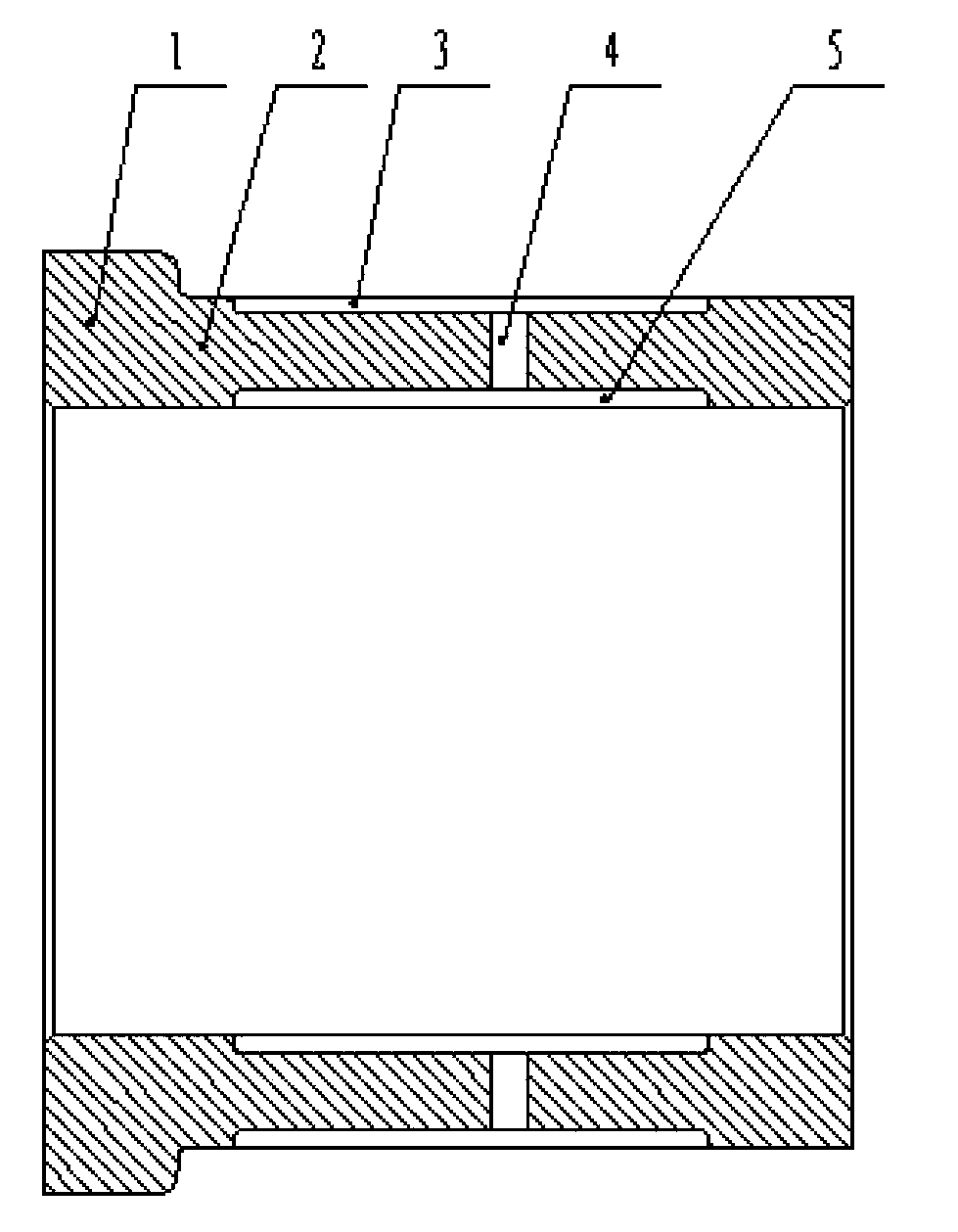

[0009] Embodiments of the present invention will be further described in detail below in conjunction with the accompanying drawings.

[0010] Such as figure 1 and figure 2 As shown, the aluminum-based alloy sliding bearing includes a fixed boss 1, a bearing body 2, an outer oil groove 3, an oil through hole 4, and an inner oil groove 5. The fixed boss 1 is connected to the bearing body 2, and the outer oil groove 3 is connected to the bearing body 2. , the outer oil groove 3 is connected to the oil hole 4, the oil hole 4 is connected to the bearing body 2, the oil hole 4 is connected to the inner oil groove 5, the inner oil groove 5 is connected to the bearing body 2, the outer oil groove 3 is 6 mm wide, and the groove depth is 4 mm. Both ends are arc-shaped transitions, eight outer oil grooves 3 are evenly distributed along the circumference of the bearing body 2, inner oil grooves 5 are 5 mm wide and 3 mm deep, and both ends of the grooves are arc-shaped transitions, eight...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com