A control reversing device for the gas circuit of an oxygen concentrator

The technology of an oxygen concentrator and a reversing device is applied in the direction of valve devices, mechanical equipment, engine components, etc., which can solve the problems of unsuitability for mass production, low work efficiency, complex circuits, etc., and achieve simple structure, low cost, and high efficiency. flexible effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The technical solution of the present invention is further described below in conjunction with the accompanying drawings, but the scope of protection is not limited to the description.

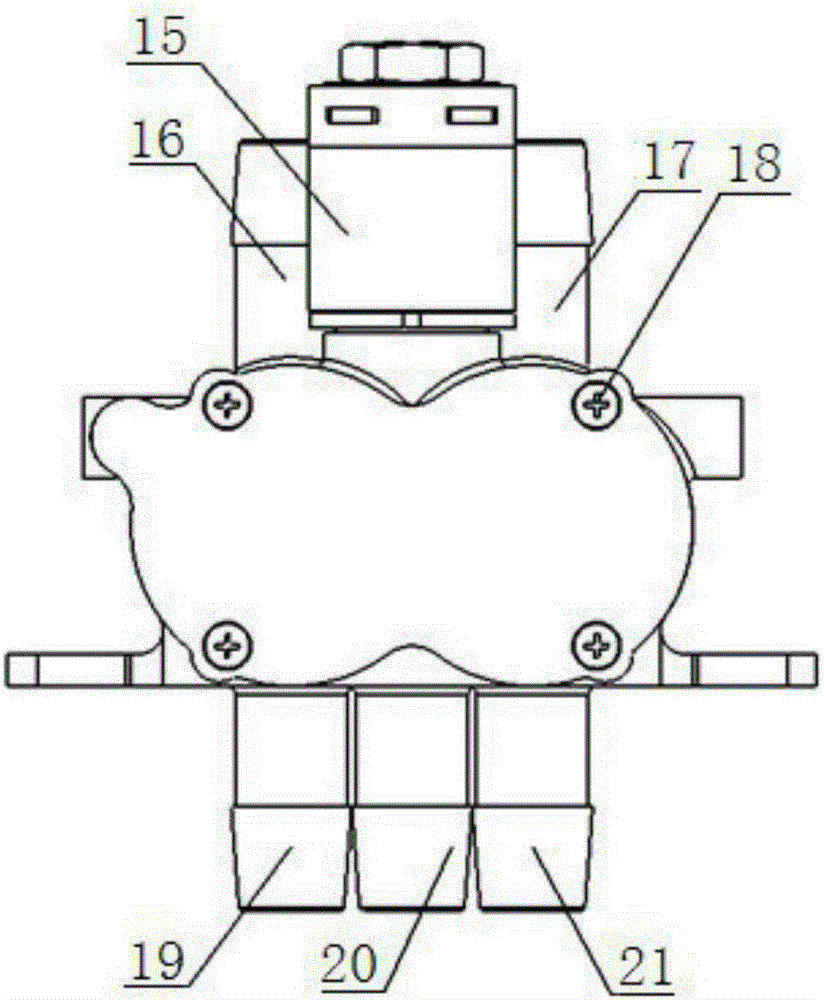

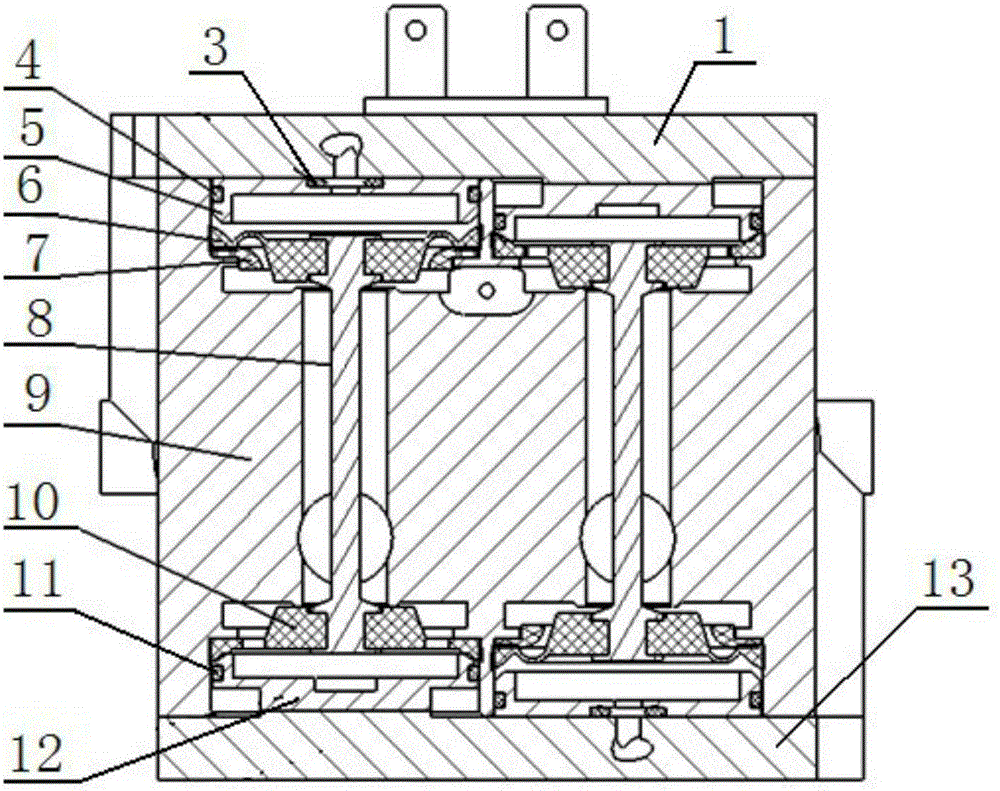

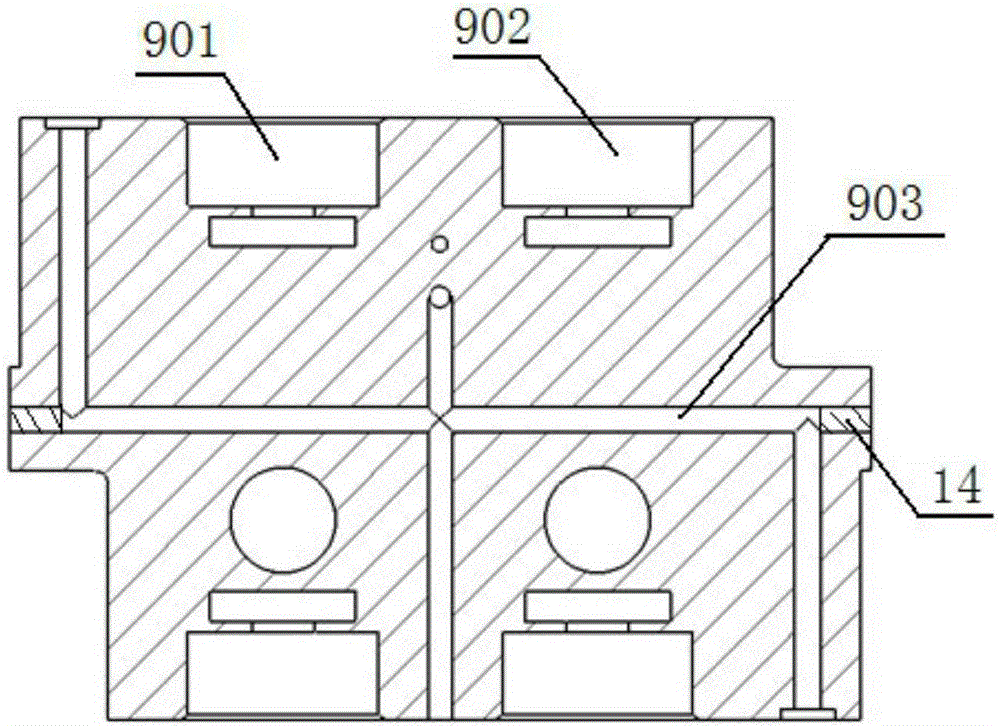

[0026] like Figure 1 to Figure 6 As shown, a control reversing device for the gas circuit of an oxygen concentrator according to the present invention includes an upper cover plate 1, a valve body 9 and a lower cover plate 13, and a left cavity 901 and a right cavity 901 are arranged inside the valve body 9. Cavity 902, in the left cavity 901 and the right cavity 902 of the valve body 9, the support frame 7, the linkage assembly, the upper end cover sealing assembly and the lower end cover sealing assembly are respectively installed, the upper cover plate 1 and the lower cover plate 13 Installed on the valve body 9 by screws 18, the valve body 9 is provided with a valve body gas path 903, and a cover plate gas path 101 is provided on the upper cover plate 1 and the lower cover plate 13...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com