A contact sealed inverted gas wave refrigerator

A gas wave refrigerator and contact sealing technology, which is applied in the field of pressure gas expansion refrigeration, can solve problems such as vibration, vibration receiving tube fracture, and severe noise, and achieve the goals of simplifying the lubrication and cooling system, improving manufacturing precision, and improving refrigeration efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] Embodiments of the present invention will be further described in detail below in conjunction with the accompanying drawings.

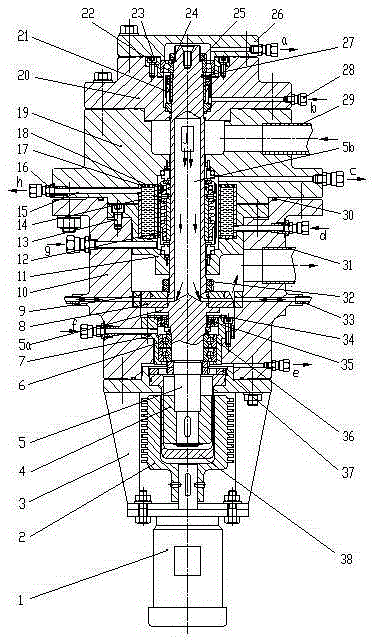

[0034] Figure 1 shows the structure diagram of a contact sealed inverted gas wave refrigerator. In the figure, the contact seal inverted type gas wave refrigerator includes the shell of the machine composed of the main body 10, the upper body 19, the upper transition box seat 20, the top cover 26 and the coupling support 3, etc. There are a main shaft mechanism that drives the rotating nozzle 8 to rotate, a supporting device for the main shaft, a mechanical sealing device and a cooling and lubricating system. From top to bottom, the body is fixedly connected together by the top cover 26, the upper transition box seat 20, the upper body 19, the main body 10, the coupling support 3 and the motor 1. The shaft is connected to the main shaft 5, and a boss plane is used to fix the rotating nozzle 8 on the main shaft 5. Since the motor is at the bott...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com