Rotary type vehicle-wheel airtightness detection machine

一种检测机、旋转式的技术,应用在车辆的测试、流体密封性的测试、通过在漏泄点检测流体的出现等方向,能够解决设备磨损、不能方便、没有车轮等问题,达到性能安全稳定、工艺先进、自动化程度高的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

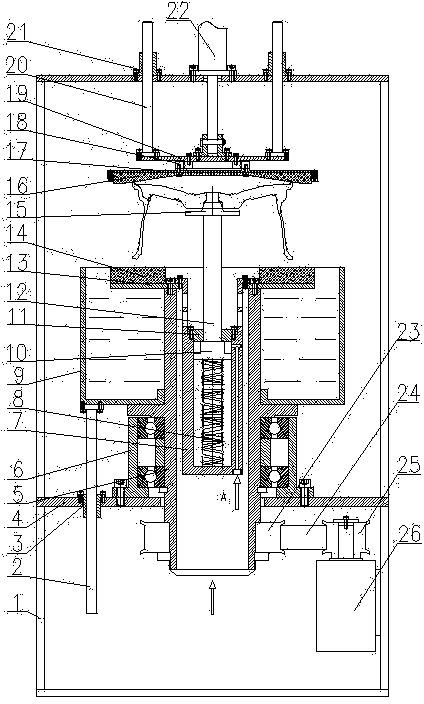

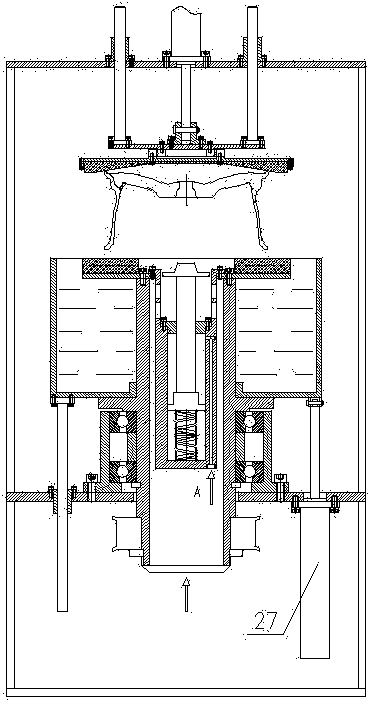

[0013] The details and working conditions of the specific device proposed according to the present invention will be described below in conjunction with the accompanying drawings.

[0014] The device consists of frame 1, guide column I2, guide sleeve I3, lower platform 4, hollow shaft 5, bearing seat 6, cylinder barrel 7, spring 8, water tank 9, piston 10, cylinder head 11, cylinder rod 12, upper platform 13. Lower seal 14, guide flange 15, upper seal 16, lower plate 17, swivel 18, upper plate 19, guide post Ⅱ20, guide sleeve Ⅱ21, compression cylinder 22, pulley Ⅰ23, synchronous belt 24, pulley II 25, motor 26 and lifting cylinder 27 are formed. The four guide sleeves I3 are fixed on the lower platform 4, and cooperate with the four guide columns I2 on which the water tank 9 is fixed at the upper end; the lifting cylinder 27 is also fixed on the lower platform 4, and its output rod is hinged to the bottom of the water tank 9; the upper platform is installed at the upper end 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com