An experimental device for dynamic demonstration of cutting tool working angle changes

A technology of working angle and cutting processing, which is applied in the field of experimental teaching aids, can solve the problems of irrational effect, not intuitive enough, and poor help in learning and understanding the working angle of cutting tools, and achieve the effect of simple structure, easy operation and strong help

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

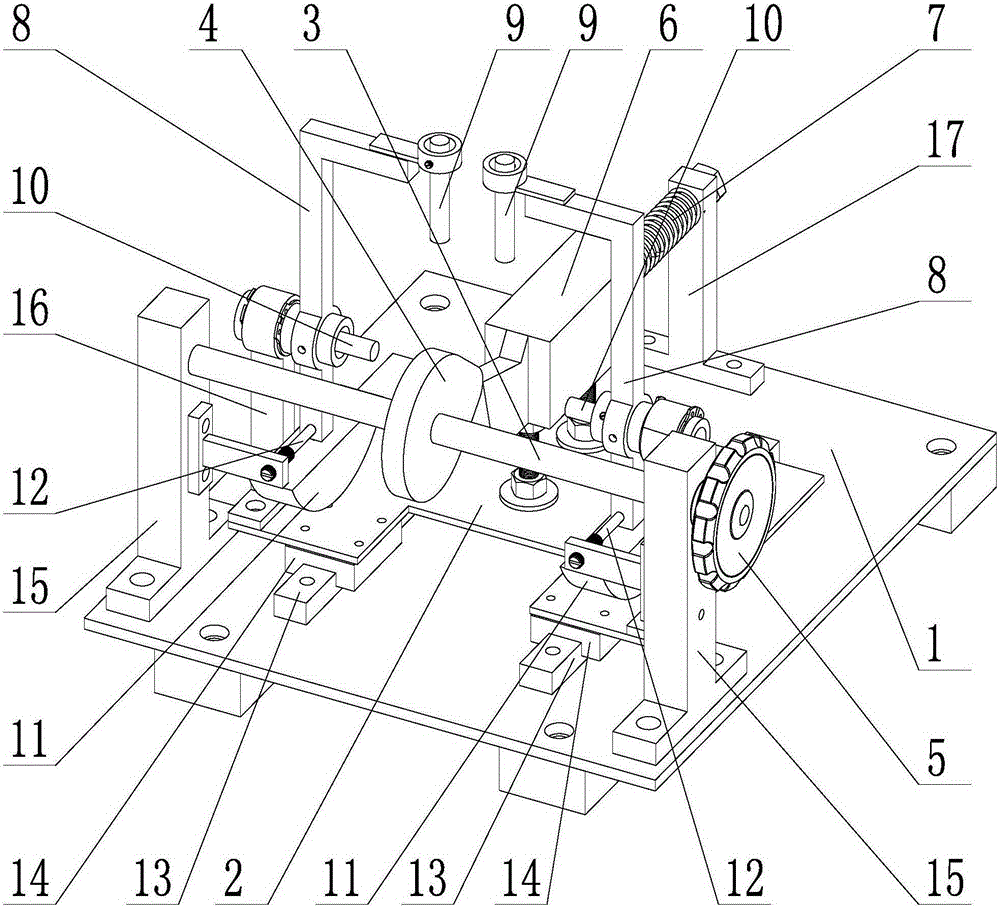

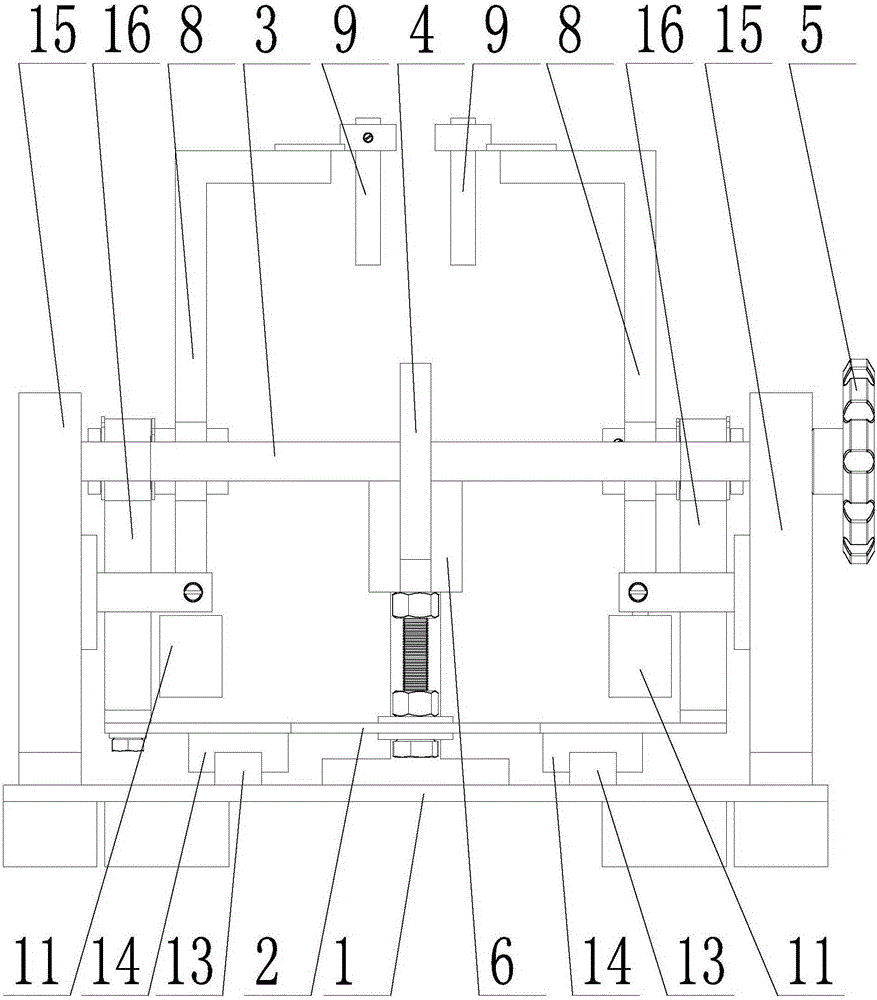

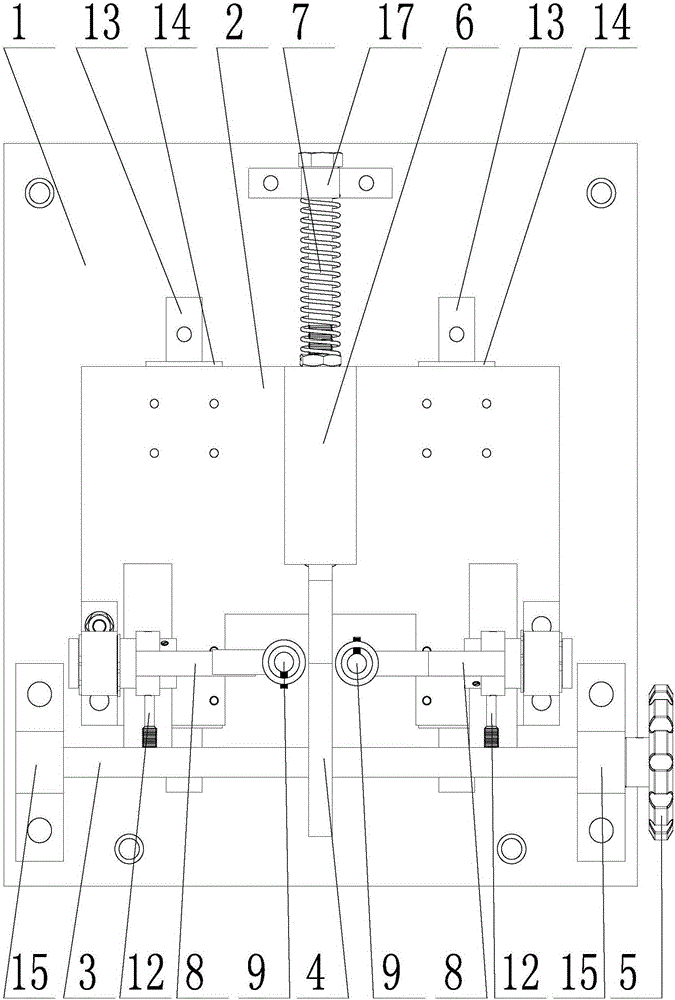

[0022] Such as figure 1 , 2 , 3, and 4, a dynamic demonstration experimental device for cutting tool working angle changes, including a fixed base plate 1, a sliding base plate 2, a rotary shaft 3, a cam 4, a tool 6, a swing frame 8, a vertical light source 9 and a horizontal light source 10. The sliding bottom plate 2 is arranged above the fixed bottom plate 1, and the sliding bottom plate 2 is slidably matched with the fixed bottom plate 1. The tool 6 is fixed on the sliding bottom plate 2, and a spring 7 is connected to the tail end of the tool 6, and the spring 7 passes through The third support 17 is fixed on the fixed base plate 1;

[0023] The rotary shaft 3 is installed on the fixed base plate 1 through the first support 15, the rotary shaft 3 is perpendicular to the feed direction of the tool 6, the cam 4 is fixedly set in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com