A kind of preparation method of finfet structure

A wet etching and fin-shaped technology, which is applied in the field of FINFET structure preparation, can solve problems such as nitride removal defects, achieve the effect of avoiding incomplete removal, increasing the contact area, and the method is simple and easy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

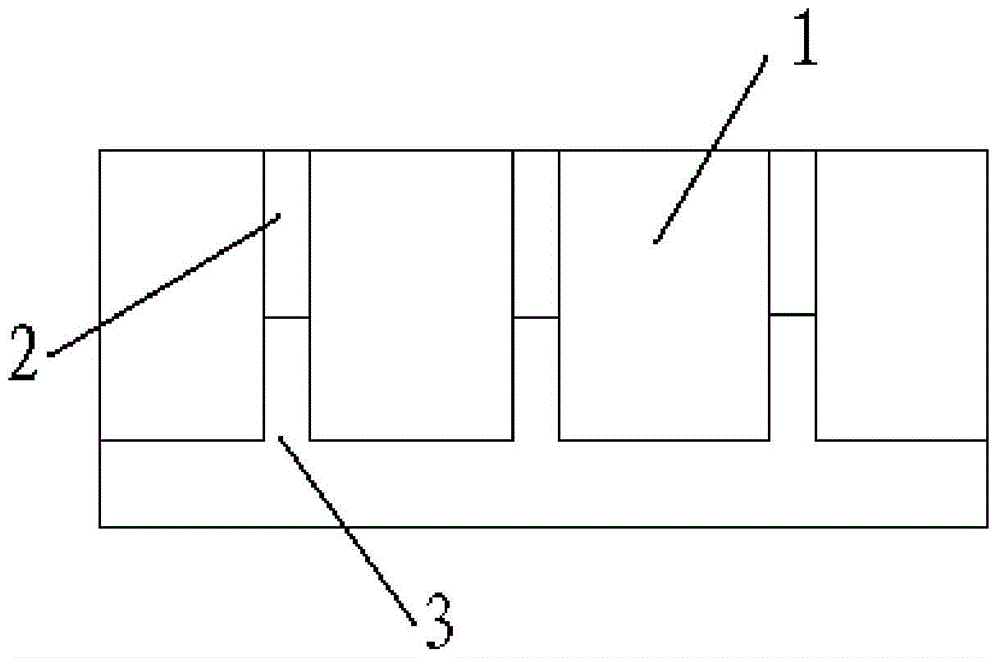

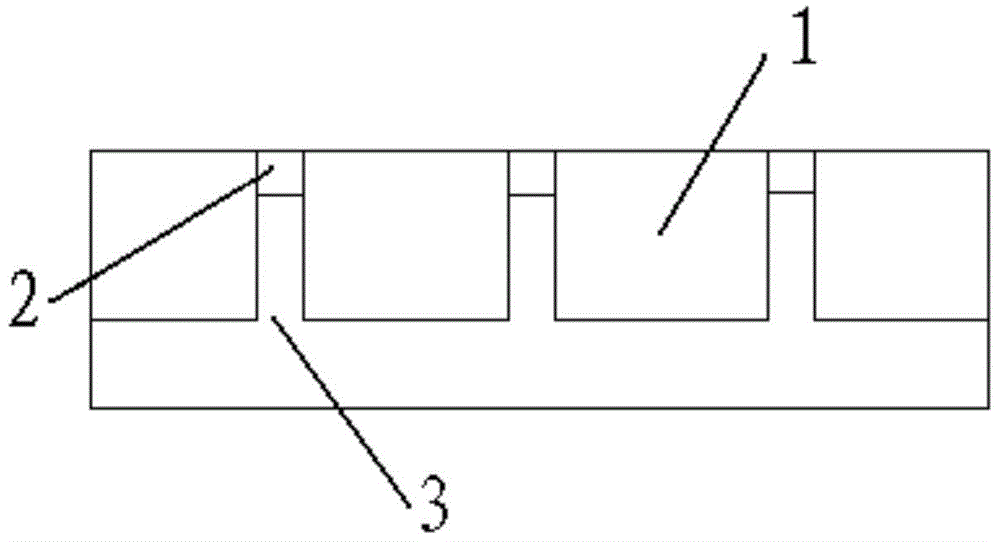

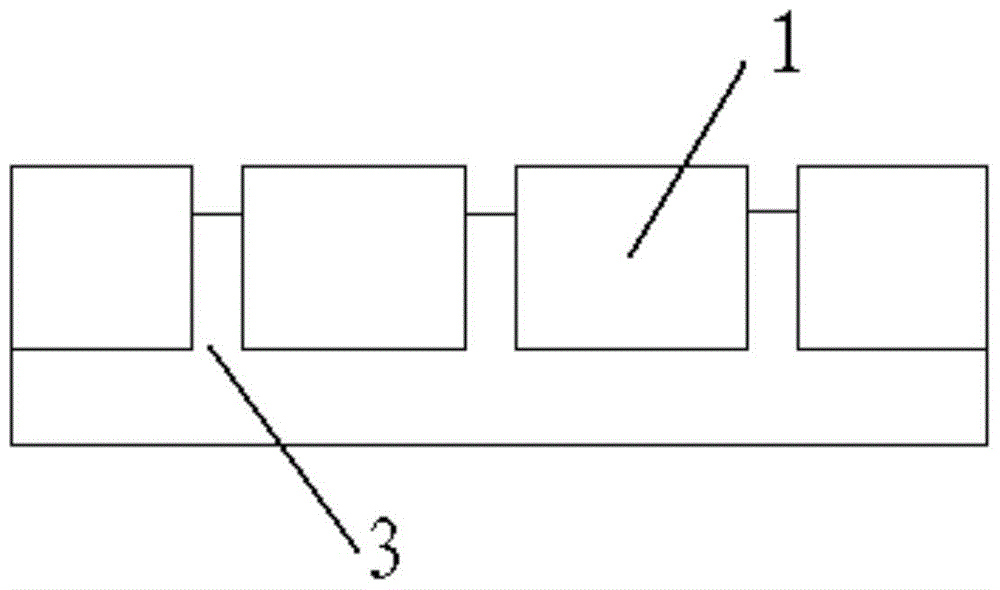

[0030] The invention provides a method for preparing a FINFET structure. After the conventional first step of CMP is completed, the grinding liquid with a low selectivity ratio is further used for grinding to reduce the thickness of silicon nitride, and finally make the silicon nitride reach an acceptable thickness. Meets the requirements for subsequent wet removal. Compared with the prior art, this method reduces the thickness of silicon nitride, and after a period of grinding, the width of exposed silicon nitride will also increase, which will be beneficial to wet cleaning. And because the rate of removal of silicon oxide by the low-selectivity slurry is greater than that of silicon nitride, after a period of grinding, the silicon nitride is in a raised state, which is more conducive to the removal of wet methods, and finally achieves the complete removal of silicon nitride. Effect.

[0031] The method of the present invention will be described in detail below in conjunctio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com