Ethyl acetate extract product of gentrin knotweed, preparation method and application thereof

A technology of ethyl acetate extraction and ethyl acetate extraction, which is applied in the field of ethyl acetate extract of Polygonum cuspidatum and its preparation, can solve the problems that there is no ethyl acetate extract, and achieve the prevention and treatment of senile dementia and the inhibition of butyrylcholine Effect of esterase activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

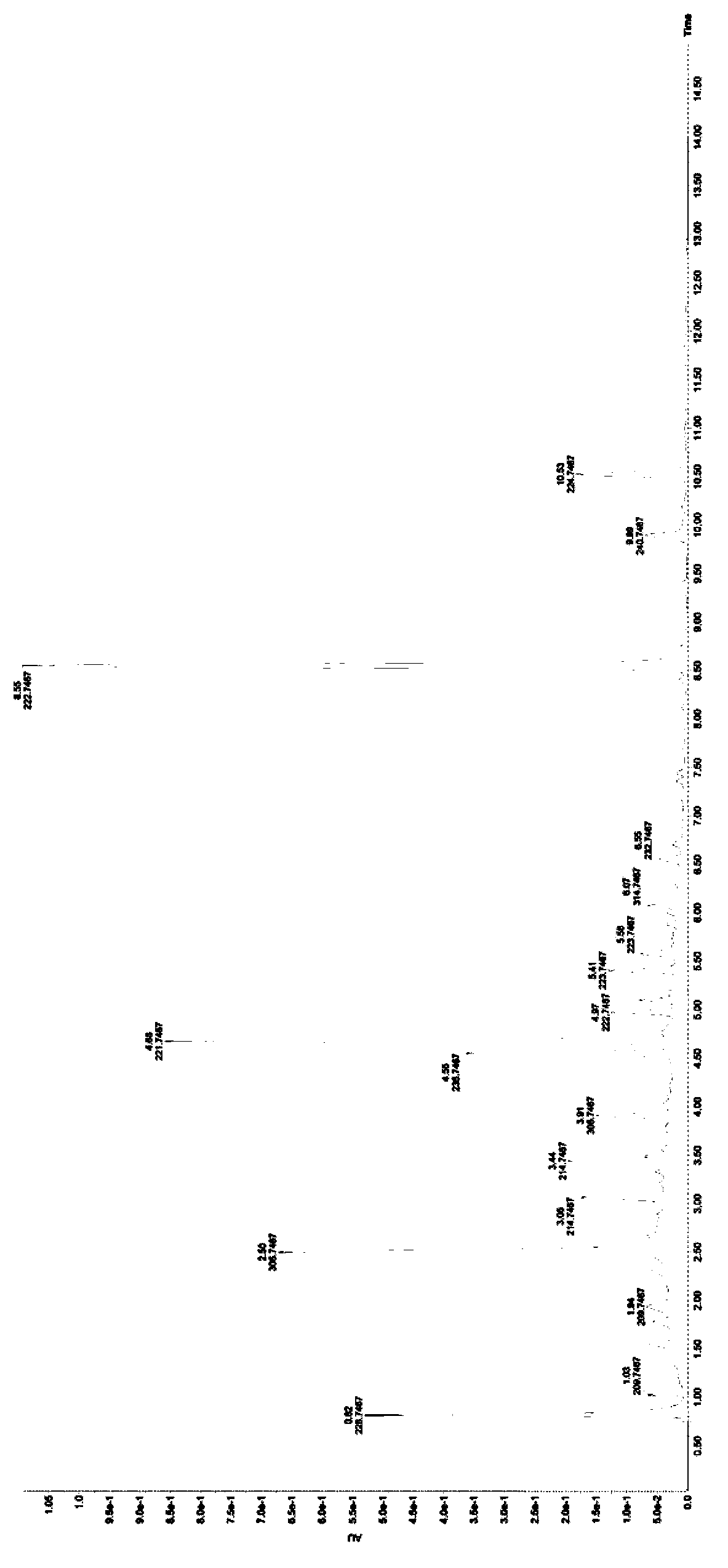

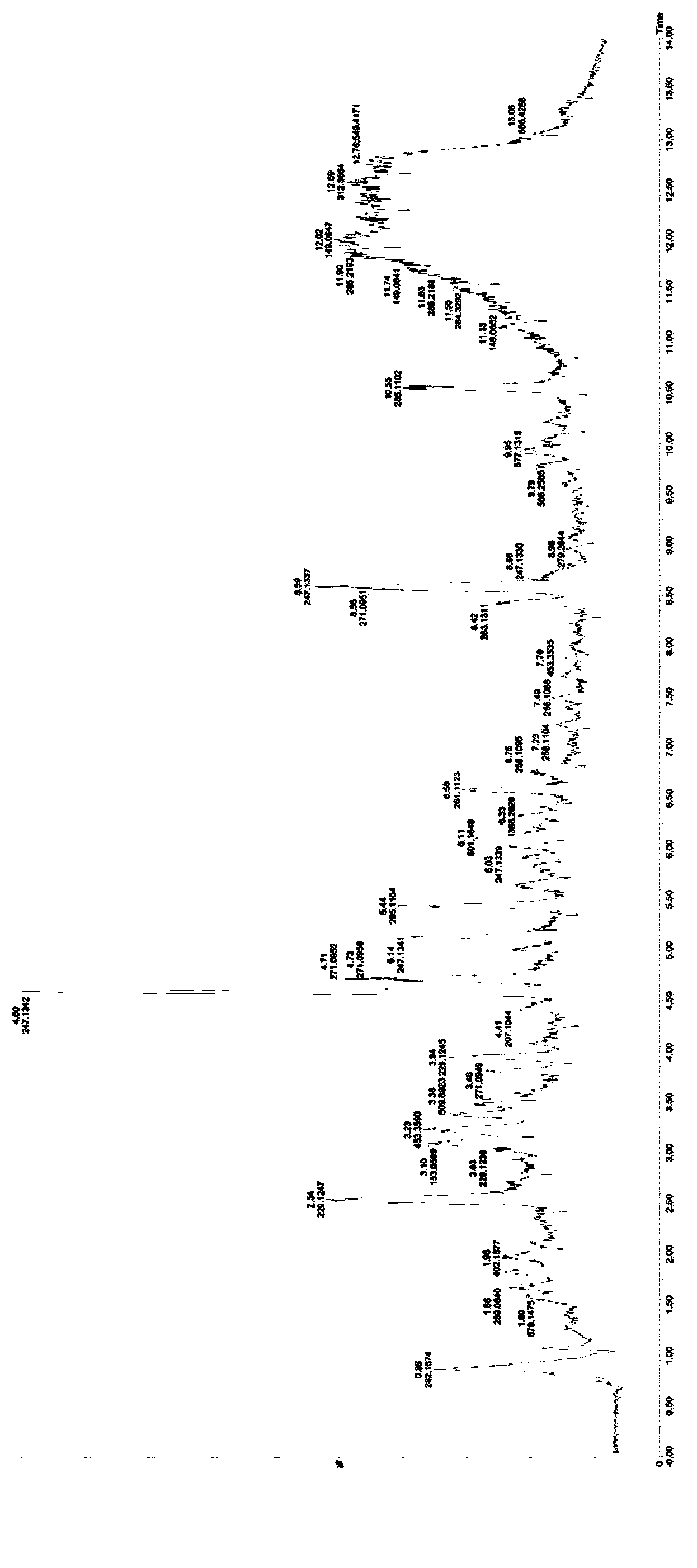

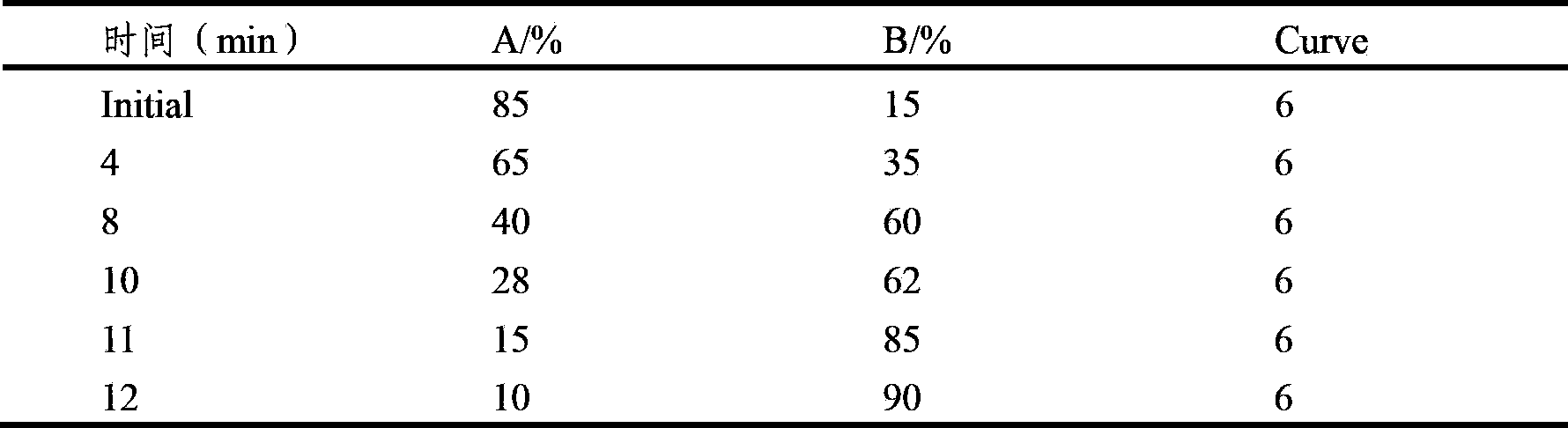

Image

Examples

Embodiment 1

[0045] Example 1: Ethyl acetate extract of Polygonum cuspidatum

[0046] 1. Pulverize the knotweed into coarse powder, weigh 500g of knotweed, soak it in 1500ml of petroleum ether three times the weight of the knotweed for 24 hours, and percolate with petroleum ether until the color of the percolate becomes lighter (2500ml of petroleum ether leachate is obtained), recycling residue;

[0047] 2. Drain the solvent in the residue, then extract the residue with 2500ml of 80% ethanol for 2 times, each extraction time is 2h, combine the two alcohol extracts, concentrate it under reduced pressure until there is no alcohol smell, and then mix with etc. Volume of ethyl acetate was extracted, the supernatant was collected, and the extract was evaporated to dryness to obtain 6.69 g of ethanol extract and ethyl acetate extract (yield 1.34%).

Embodiment 2

[0048] Example 2: Ethyl acetate extract of Polygonum cuspidatum

[0049] 1. Pulverize the knotweed into coarse powder, weigh 500g of knotweed, soak it in petroleum ether 5 times the volume (2500ml) of the weight of knotweed for 36 hours, and permeate with petroleum ether until the color of the percolating liquid becomes lighter (obtain 3500ml of filtrate), the residue is recovered;

[0050] 2. Drain the solvent in the residue, then extract the residue twice with 3500ml of 90% ethanol, the extraction time is 3 hours and 2 hours in turn, combine the extracts, and then concentrate until there is no alcohol smell, and then mix with an equal volume of ethanol. Extract with ethyl acetate, collect the supernatant, evaporate to dryness to obtain 4.014 g of ethyl acetate extract (yield: 0.803%).

Embodiment 3

[0051] Example 3: Ethyl acetate extract of Polygonum cuspidatum

[0052] 1. Crushed Polygonum cuspidatum into coarse powder, take 500g of it and soak it in petroleum ether with 3 times the volume (2000ml) of the weight of Polygonum cuspidatum for 18 hours, and percolate until the color of the leachate becomes lighter (3000ml of petroleum ether leachate is obtained), and the residue is recovered. ;

[0053] 2. Drain the solvent in the residue, then extract the residue with 1500ml of 70% ethanol for 3 times, the extraction time is 2 hours, 1.5 hours, 1.5 hours in turn, combine the extracts, and concentrate them under reduced pressure until there is no alcohol smell , and then extracted with an equal volume of ethyl acetate, the supernatant was collected and evaporated to dryness to obtain 5.352 g of ethyl acetate extract (1.07% yield).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com