Stirrer with high stirring strength and high shearing force

A technology of stirring strength and high shear force, applied in mixers with rotary stirring devices, chemical instruments and methods, dissolution and other directions, can solve the problems of energy waste, equipment idling loss, reduction of cylinder height-diameter ratio, etc. The effect of reducing energy consumption and operating costs, less maintenance failure points, and reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be described in detail below in conjunction with the accompanying drawings.

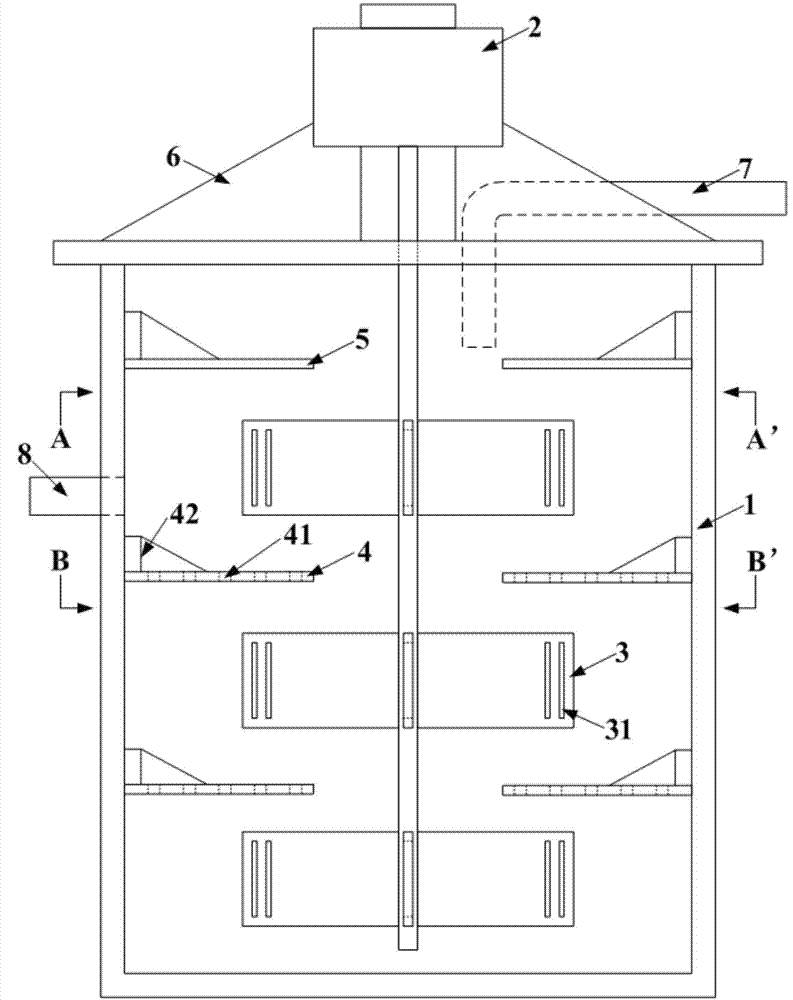

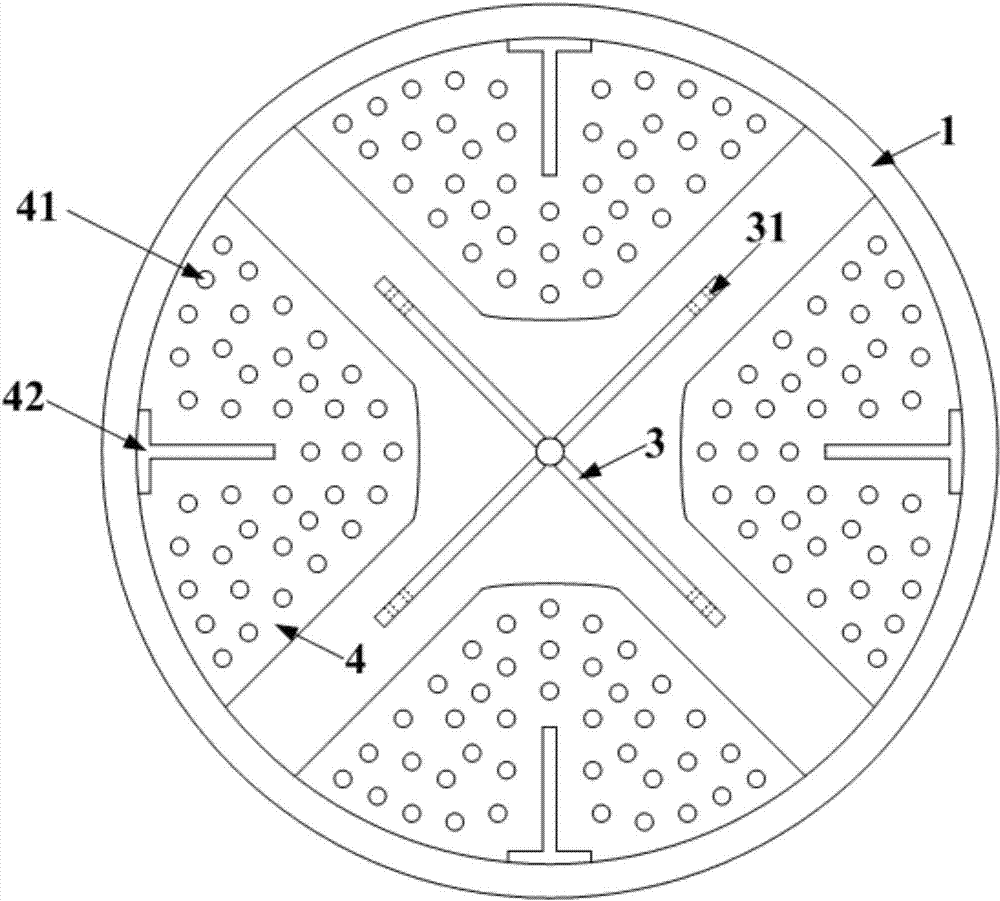

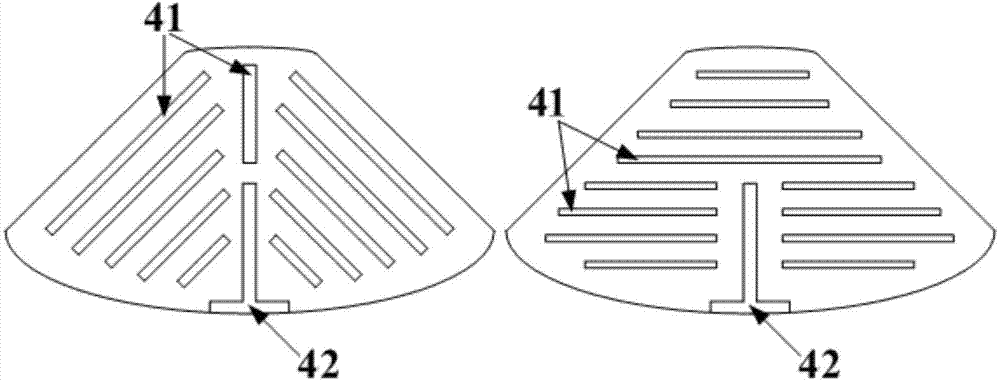

[0018] figure 1 It is a structural schematic diagram of an embodiment of the present invention, comprising a cylinder 1, a permanent magnet direct drive motor 2 and a feed inlet 7 are arranged on the top of the cylinder 1, the permanent magnet direct drive motor 2 is directly connected with the rotating shaft of the stirring paddle, and simultaneously The fixed bracket 6 fixes the permanent magnet direct drive motor 2 on the cylinder body 1, the control end of the motor is connected with the frequency conversion speed control machine, and the feeding port 7 is used for connecting with upstream equipment. The directly connected permanent magnet direct drive motor 2 greatly increases the torque of the agitator, while reducing energy consumption and maintenance costs.

[0019] After the fluid material enters the cylinder 1 through the feed port 7, it flows downward alo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com