Environmental-protection waste gas heat exchange comprehensive utilization carbon drying kiln

An environmentally friendly, drying kiln technology, applied in drying, dryers, heating devices, etc., can solve problems such as air pollution, human health hazards, and inability to achieve, reduce energy consumption and operating costs, and save environmental protection costs , to achieve the effect of energy reuse

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

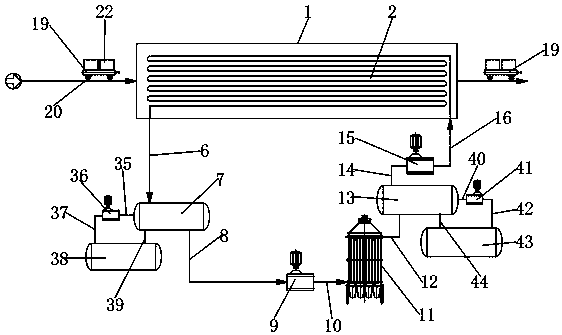

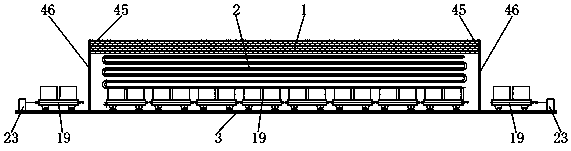

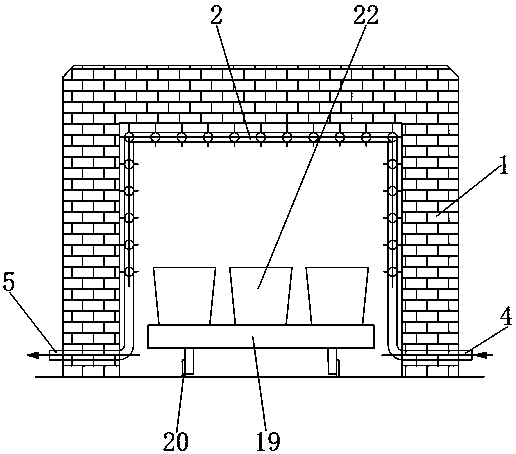

[0024] Below in conjunction with accompanying drawing and specific embodiment the present invention will be described in further detail:

[0025] see Figure 1 to Figure 7 , the present invention provides an environment-friendly exhaust gas heat exchange comprehensive utilization charcoal drying kiln, comprising a tunnel-shaped heat exchange kiln 1, the inner wall of the heat exchange kiln 1 is provided with a disc-shaped oil pipe 2; the lower inner wall of the heat exchange kiln 1 A calcium carbide feeder track 3 is provided; a calcium carbide conveying device matching it is provided on the calcium carbide feeder track 3; a coil inlet 4 and a coil outlet 5 are respectively provided at both ends of the coiled oil pipe 2; The pipe outlet 5 is connected to a high-temperature heat-conducting oil storage tank 7 through a first high-temperature oil pipe 6; the high-temperature heat-conducting oil storage tank 7 is connected to the first oil pump 9 through a second high-temperature ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com