Method of reducing sludge of petrochemical wastewater by aerating combination of ozone and pure oxygen

A technology of pure oxygen aeration and petrochemical wastewater, which is applied in the field of environmental engineering, can solve the problems of high energy consumption, high inorganic salt content, high sludge yield, etc., to reduce energy consumption and operation costs, improve treatment efficiency, and reduce residual sewage. The effect of reducing the amount of mud

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

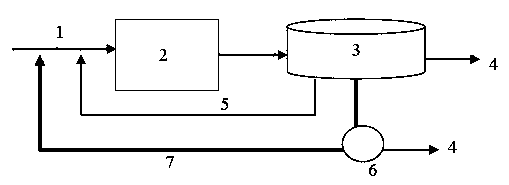

Image

Examples

Embodiment 1

[0024] Example 1: When the test pure oxygen aeration tank is operating at full capacity, the remaining sludge is oxidized by ozone.

[0025] 1. Pump the sewage into the pure oxygen aeration tank with an effective volume of 1000L, and inject pure oxygen into the tank for aeration; the pure oxygen aeration tank is controlled to operate at full load, and the corresponding HRT is 12h.

[0026] 2. The sewage after pure oxygen aeration is pumped into the conical sedimentation tank for 1.0h, and then filtered to complete the solid-liquid separation. 50% of the separated sludge is used as return sludge, and the remaining 50% is used as ozonated sludge;

[0027] 3. Then pump the return sludge separated from the conical sedimentation tank to the pure oxygen aeration tank with an effective volume of 1000L as described in step 1. The return sludge concentration is 16g / L, and the water volume in the tank is maintained. At 900L, keep the oxygen pipe valve open at the same time for aeration....

Embodiment 2

[0029] Example 2: When the pure oxygen aeration tank is running at half load, the remaining sludge is oxidized by ozone.

[0030] 1. Pump the sewage into the pure oxygen aeration tank with an effective volume of 1000L, and inject pure oxygen into the tank for aeration. The pure oxygen aeration tank is controlled to operate at half load, and the corresponding HRT is 24h.

[0031] 2. The sewage after pure oxygen aeration is pumped into the conical sedimentation tank to settle for 2 hours, and then filtered to complete the solid-liquid separation, 60% of the separated sludge is used as return sludge, and the remaining 40% is used as ozonated sludge;

[0032] 3. Then pump the return sludge separated from the conical sedimentation tank to the pure oxygen aeration tank with an effective volume of 1000L as described in step 1. The return sludge concentration is 18g / L, and the water volume in the tank is maintained. At 920L, keep the oxygen pipe valve open at the same time for aeratio...

Embodiment 3

[0034] Example 3: When the pure oxygen aeration tank is running at half load, the remaining sludge is oxidized by ozone.

[0035] 1. Pump the sewage into the pure oxygen aeration tank with an effective volume of 1000L, and inject pure oxygen into the tank for aeration. The pure oxygen aeration tank is controlled to operate at half load, and the corresponding HRT is 24h.

[0036] 2. The sewage after pure oxygen aeration is pumped into the conical sedimentation tank for sedimentation for 2 hours, and then filtered to complete solid-liquid separation. 55% of the separated sludge is used as return sludge, and the remaining 45% is used as ozonated sludge;

[0037] 3. Then pump the return sludge separated from the conical sedimentation tank to the pure oxygen aeration tank with an effective volume of 1000L as described in step 1. The return sludge concentration is 16g / L, and the water volume in the tank is maintained. At 900L, keep the oxygen pipe valve open at the same time for aer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com