A Coal Chemical Wastewater Biological Treatment System and Treatment Method Based on Sludge Ozone Catalytic Oxidation

A technology for ozone catalytic oxidation and coal chemical wastewater treatment, which is applied in the fields of oxidized water/sewage treatment, water/sludge/sewage treatment, anaerobic digestion treatment, etc. The problem of low rate of sludge digestion can be achieved to achieve the effect of low-cost sludge digestion promotion, beneficial to reduction, and complete sludge digestion.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

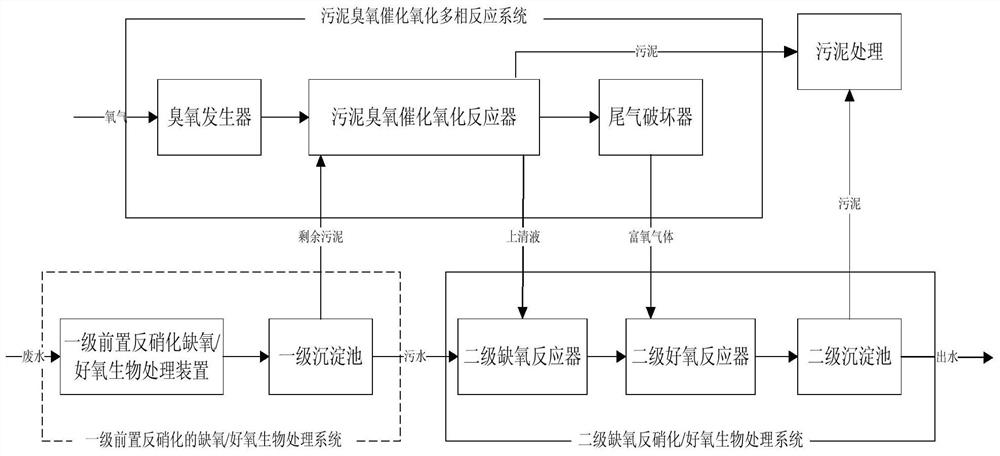

[0093] This embodiment provides a biological treatment system for coal chemical wastewater, which includes a first-stage pre-denitrification anoxic / aerobic biological treatment system, a sludge ozone catalytic oxidation multi-phase reaction system and a second-stage anoxic denitrification / Aerobic biological treatment system;

[0094] Among them, the first-stage sedimentation tank in the anoxic / aerobic biological treatment system with pre-denitrification and the sludge ozone catalytic oxidation reactor in the sludge ozone catalytic oxidation multiphase reaction system are connected through sludge pipelines, and the sludge The clear liquid outlet of the ozone catalytic oxidation reactor in the ozone catalytic oxidation multiphase reaction system and the sewage discharge outlet of the primary sedimentation tank in the anoxic / aerobic biological treatment system of primary pre-denitrification are simultaneously connected with the secondary The liquid inlet of the secondary anoxic...

Embodiment 2

[0101] In this embodiment, the coal chemical wastewater biological treatment system described in Example 1 is used to treat the coal chemical wastewater. The COD content in the coal chemical wastewater to be treated is 3000-8000 mg / L, and the ammonia nitrogen content is 50-300 mg / L.

[0102] The coal chemical wastewater to be treated enters the anoxic / aerobic biological treatment system of the first-level pre-denitrification for the first-level anoxic treatment, the first-level aerobic treatment and the first-level sedimentation treatment. Among them, the first-level anoxic treatment adopts biological Membrane method, the primary aerobic treatment adopts the activated sludge method, the hydraulic retention time in the primary anoxic reactor is 25-30h, the hydraulic retention time in the primary aerobic reactor is 60-70h, and the primary The total hydraulic retention time of the denitrification anoxic / aerobic biological treatment unit is 100-120h.

[0103] The concentration of ...

Embodiment 3

[0108] In this example, the coal chemical wastewater biological treatment system described in Example 1 is used to treat coal chemical wastewater. Except that the hydraulic retention time in the primary anoxic reactor is 40-45h, the hydraulic retention time in the primary aerobic reactor is The residence time is 80-90h, and the total hydraulic retention time of the anoxic / aerobic biological treatment unit of the first-stage pre-denitrification is 130-140h; the flow ratio of the sludge used for backflow and the sludge used for ozone catalytic digestion is 10:1; the ozone generator produces ozone with a concentration of 10-12%, and the dosage of ozone in the sludge ozone catalytic oxidation reactor is 0.05-0.06O 3 / MLSS(g / g), the ozone catalytic digestion time is 20-30min; the hydraulic retention time of the secondary anoxic treatment is 15-20h, and the hydraulic retention time of the secondary aerobic treatment is 10-15h, other operating steps All the same as in Example 2.

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com